Marine and fishing wire rope

Ensuring Strength & Reliability at Sea

Marine and fishing wire rope is a specialized type of equipment crucial for various operations in the maritime and fishing industries. Here’s a detailed description of its attributes and uses:

1. Marine Rope

Marine rope is crucial in nautical applications, and its design is focused on strength, durability, and resistance to harsh maritime environments.

Uses:

Mooring: Securing boats to docks or piers.

Anchoring: Holding a boat in place via an anchor.

Towing: Pulling boats or other maritime structures.

Rigging: Used in the handling of sails and other equipment on boats.

Material and Construction:

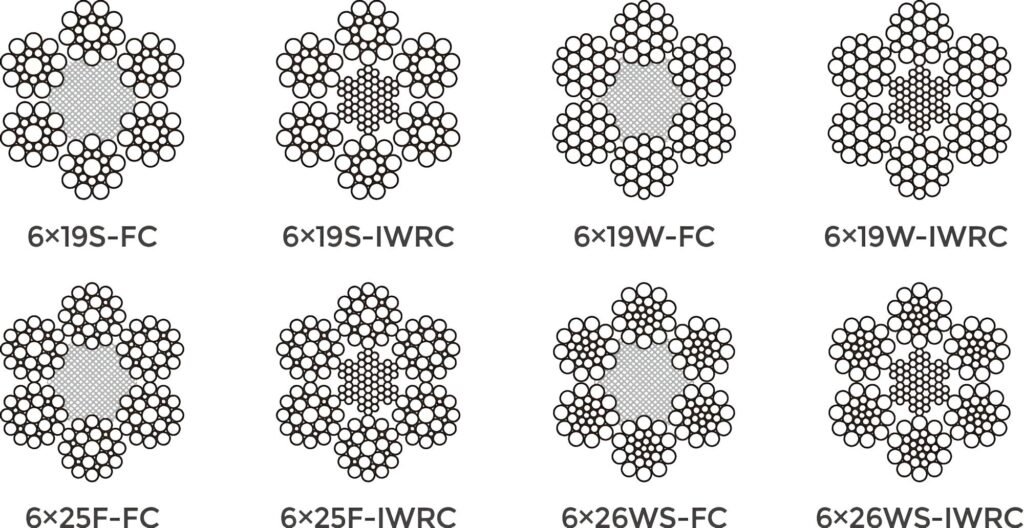

Marine and fishing wire ropes are typically made from stainless steel or galvanized steel to resist corrosion caused by saltwater and harsh marine conditions. These ropes consist of several strands of wire twisted together to provide strength and flexibility. The specific construction of the wire rope can vary depending on its intended use, with common configurations including 6×19, 6X26, 6XK19S, 6XK26 and 8×19 strands.

Strength: Must withstand high loads without breaking.

Elasticity: Some applications require elasticity to absorb shocks.

Weather Resistance: Resistant to UV rays, saltwater, and wear.

2. Fishing Rope

Fishing rope is designed specifically for the fishing industry, tailored to handle interactions with marine life and underwater obstacles efficiently.

Uses:

Netting: Used in the construction of fishing nets.

Long-lines: For long-line fishing, where baited hooks are spread out over large distances.

Trawling: Heavy ropes used for dragging fishing nets.

Materials:

Polyethylene: Common for fishing nets due to its durability and resistance to chemicals and water.

Braided Spectra: Used for deep-sea fishing lines because of its extreme strength and resistance to abrasion.

Monofilament Nylon: Popular for its stretch and invisibility underwater, suitable for lines in clear water.

Properties:

Abrasion Resistance: Essential for ropes that contact with underwater surfaces.

Controlled Stretch: Important for managing the impact of large fish.

Buoyancy: Some ropes need to float, while others must sink, depending on the fishing technique.

Both types of ropes share the need for resilience and strength but are differentiated by their specific applications and the environments in which they are used. Their construction and material composition are directly influenced by their required mechanical properties and environmental resilience.

Steel Wire Rope

Advantage

- Proven strand design and high adaptability.

- Fit-for-purpose, robust rope construction.

- Fully lubricated during manufacturing.

- Low maintenance costs, fair cost-benefit ratio.

| Diameter (mm) | Approx. weight (kg/100m) | Tensile strength (MPa) | ||||||||

| 1570 | 1770 | 1960 | 2160 | |||||||

| Minimum breaking load (kN) | ||||||||||

| (mm) | FC | WC | FC | WC | FC | WC | FC | WC | FC | WC |

| 6 | 13.7 | 15.0 | 18.7 | 20.1 | 21 | 22.7 | 23.3 | 25.1 | 25.7 | 27.7 |

| 7 | 18.6 | 20.5 | 25.4 | 27.4 | 28.6 | 30.9 | 31.7 | 34.2 | 34.9 | 37.7 |

| 8 | 24.3 | 26.8 | 33.2 | 35.8 | 37.4 | 40.3 | 41.1 | 44.7 | 45.6 | 49.2 |

| 9 | 30.8 | 33.9 | 42 | 45.3 | 47.3 | 51 | 52.4 | 56.5 | 57.5 | 62.3 |

| 10 | 38.0 | 41.8 | 51.8 | 55.9 | 58.4 | 63 | 64.7 | 69.8 | 71.3 | 76.9 |

| 11 | 46.0 | 50.6 | 62.7 | 67.6 | 70.7 | 76.2 | 78.3 | 84.4 | 86.2 | 93.0 |

| 12 | 54.7 | 60.2 | 74.6 | 80.5 | 84.1 | 90.7 | 93.1 | 100 | 103 | 111 |

| 13 | 64.2 | 70.6 | 87.6 | 94.5 | 98.7 | 106 | 109 | 118 | 120 | 130 |

| 14 | 74.5 | 81.9 | 102 | 110 | 114 | 124 | 127 | 137 | 140 | 151 |

| 16 | 97.3 | 107 | 133 | 143 | 150 | 161 | 166 | 179 | 182 | 197 |

| 18 | 123 | 135 | 168 | 181 | 189 | 204 | 210 | 226 | 231 | 249 |

| 20 | 152 | 167 | 207 | 224 | 234 | 252 | 259 | 279 | 285 | 308 |

| 22 | 184 | 202 | 251 | 271 | 283 | 305 | 313 | 338 | 345 | 372 |

| 24 | 219 | 241 | 298 | 322 | 336 | 363 | 373 | 402 | 411 | 443 |

| 26 | 257 | 283 | 350 | 378 | 395 | 426 | 437 | 472 | 482 | 520 |

| 28 | 298 | 328 | 406 | 438 | 458 | 494 | 507 | 547 | 559 | 603 |

| 32 | 389 | 428 | 531 | 572 | 598 | 645 | 662 | 715 | 730 | 787 |

| 36 | 492 | 542 | 671 | 724 | 757 | 817 | 838 | 904 | 924 | 997 |

| 40 | 608 | 669 | 829 | 894 | 935 | 1010 | 1030 | 1120 | 1140 | 1230 |

| 44 | 736 | 809 | 1000 | 1080 | 1130 | 1220 | 1250 | 1350 | 1380 | 1490 |

| 48 | 876 | 963 | 1190 | 1290 | 1350 | 1450 | 1490 | 1610 | 1640 | 1770 |

| 52 | 1030 | 1130 | 1400 | 1510 | 1530 | 1700 | 1750 | 1890 | 1930 | 2080 |

| 56 | 1190 | 1310 | 1620 | 1750 | 1830 | 1980 | 2030 | 2190 | 2240 | 2410 |

Rope type:6×K19, 6×K36

Rope Construction:6XK19S, 6×K26WS, 6×K31WS, 6×K36WS, 6×K41WSIn accordance with the EN 12385-4 standard.

Different constructions depending on the diameter.

Grade:1770mpa,1960mpa,2160mpa

Lay: sZ,zS,zZ,sS

Our Advantage

- Abrasion resistance performance.

- High breaking force.

- Fatigue resistant performance

- Improved support of outer strands in service.

- Improved ton-mile performance

| Diameter (mm) | Approx. weight (kg/100m) | Tensile strength (MPa) | ||||||||||||

| 1570 | 1670 | 1770 | 1870 | 1960 | 2160 | |||||||||

| Minimum breaking load (kN) | ||||||||||||||

| FC | WC | FC | WC | FC | WC | FC | WC | FC | WC | FC | WC | FC | WC | |

| 12 | 61.2 | 67.0 | 84.3 | 93.8 | 89.7 | 99.8 | 95.1 | 106 | 100 | 112 | 105 | 117 | 116 | 129 |

| 14 | 83.3 | 91 | 115 | 128 | 122 | 136 | 129 | 144 | 137 | 152 | 143 | 159 | 158 | 176 |

| 16 | 109 | 119 | 150 | 167 | 159 | 177 | 169 | 188 | 179 | 199 | 187 | 208 | 206 | 230 |

| 18 | 138 | 151 | 190 | 211 | 202 | 225 | 214 | 238 | 226 | 251 | 237 | 264 | 261 | 290 |

| 20 | 170 | 186 | 234 | 261 | 249 | 277 | 264 | 294 | 279 | 310 | 292 | 325 | 322 | 359 |

| 22 | 206 | 225 | 283 | 315 | 301 | 335 | 320 | 356 | 338 | 376 | 354 | 394 | 390 | 434 |

| 24 | 245 | 268 | 337 | 375 | 359 | 399 | 380 | 423 | 402 | 447 | 421 | 469 | 464 | 516 |

| 26 | 287 | 314 | 396 | 440 | 421 | 469 | 446 | 497 | 472 | 525 | 494 | 550 | 545 | 606 |

| 28 | 333 | 365 | 459 | 511 | 488 | 543 | 518 | 576 | 547 | 608 | 573 | 638 | 632 | 703 |

| 30 | 382 | 419 | 527 | 586 | 561 | 624 | 594 | 661 | 628 | 698 | 658 | 732 | 725 | 807 |

| 32 | 435 | 476 | 600 | 667 | 638 | 710 | 676 | 752 | 714 | 795 | 749 | 833 | 825 | 918 |

| 34 | 491 | 538 | 677 | 753 | 720 | 801 | 763 | 849 | 806 | 897 | 845 | 940 | 931 | 1040 |

| 36 | 551 | 603 | 759 | 844 | 807 | 898 | 856 | 952 | 904 | 1010 | 947 | 1050 | 1040 | 1160 |

| 38 | 614 | 671 | 846 | 941 | 899 | 1000 | 950 | 1060 | 1010 | 1120 | 1060 | 1170 | 1160 | 1290 |

| 40 | 680 | 744 | 937 | 1040 | 1000 | 1110 | 1060 | 1180 | 1120 | 1240 | 1170 | 1300 | 1290 | 1430 |

| 42 | 750 | 820 | 1030 | 1150 | 1100 | 1220 | 1160 | 1300 | 1230 | 1370 | 1290 | 1430 | 1420 | 1580 |

| 44 | 823 | 900 | 1130 | 1260 | 1210 | 1340 | 1280 | 1420 | 1350 | 1500 | 1420 | 1570 | 1560 | 1740 |

| 46 | 899 | 984 | 1240 | 1380 | 1320 | 1470 | 1400 | 1550 | 1480 | 1640 | 1550 | 1720 | 1700 | 1900 |

| 48 | 979 | 1070 | 1350 | 1500 | 1440 | 1600 | 1520 | 1690 | 1610 | 1790 | 1680 | 1870 | 1860 | 2070 |

| 50 | 1060 | 1160 | 1460 | 1630 | 1560 | 1730 | 1650 | 1840 | 1740 | 1940 | 1830 | 2030 | 2010 | 2240 |

| 52 | 1150 | 1260 | 1580 | 1760 | 1680 | 1870 | 1790 | 1990 | 1890 | 2100 | 1980 | 2200 | 2180 | 2420 |

| 54 | 1240 | 1360 | 1710 | 1900 | 1820 | 2020 | 1930 | 2140 | 2030 | 2260 | 2130 | 2370 | 2350 | 2610 |

| 56 | 1330 | 1460 | 1840 | 2040 | 1950 | 2170 | 2070 | 2300 | 2190 | 2430 | 2290 | 2550 | 2530 | 2810 |

| 58 | 1430 | 1560 | 1970 | 2190 | 2100 | 2330 | 2220 | 2470 | 2350 | 2610 | 2460 | 2740 | 2710 | 3020 |

| 60 | 1530 | 1670 | 2110 | 2350 | 2240 | 2490 | 2380 | 2640 | 2510 | 2790 | 2630 | 2930 | 2900 | 3230 |

Synthetic rope

Synthetic ropes are increasingly popular in marine applications due to their unique properties and advantages over traditional natural fiber ropes. Here’s a detailed overview of synthetic ropes used in marine settings:

Types of Synthetic Ropes

Nylon: Known for its incredible strength and elasticity, nylon rope is commonly used for mooring, anchoring, and towing because it can absorb shock loads well.

Polyester: While it doesn’t stretch as much as nylon, polyester rope is highly resistant to abrasion and UV degradation, making it suitable for mooring lines that remain static.

Polypropylene: This is a lightweight rope that floats, which is ideal for use in fishing lines, marker buoys, and water rescue lines. It’s also quite resistant to moisture and chemicals.

HMPE (High Modulus Polyethylene): Aulone are known for high strength-to-weight ratios, excellent abrasion resistance, and buoyancy. These ropes are used in critical applications, such as the rigging on sailing boats and in commercial fishing operations.

Advantages of Synthetic Marine Ropes

Strength: Synthetic ropes generally offer greater break strength than natural fiber ropes of the same diameter.

Durability: They are resistant to rot, mildew, and corrosion by saltwater.

Lightweight: Easier handling and less labor-intensive operations, as these ropes are lighter than equivalent natural fiber ropes.

UV Resistance: Many synthetic ropes are treated for UV protection to enhance longevity, especially important in sun-exposed maritime environments.

Elasticity: Certain types like nylon provide elasticity, which helps absorb sudden loads smoothly.

Applications in Marine Settings

Mooring Lines: Used to secure boats to docks or mooring buoys; synthetic ropes offer the required strength and durability.

Towing Lines: For towing boats or other marine structures, synthetic ropes provide strength and shock absorption.

Fishing Lines: Synthetic ropes are used in commercial fishing for nets and trawls due to their durability and resistance to rotting in wet conditions.

Sailing Rigging: On sailboats, synthetic ropes are favored for running rigging due to their strength, light weight, and low stretch.

Maintenance and Care

While synthetic ropes are robust, they require proper maintenance to maximize their lifespan:

Regular Inspections: Check for signs of wear, abrasion, or chemical damage.

Proper Storage: Store ropes dry and away from direct sunlight when not in use.

Cleaning: Wash with fresh water to remove salt and debris, which can degrade the fibers over time.

Synthetic ropes have revolutionized marine operations with their advanced properties, providing enhanced safety, efficiency, and reliability in diverse maritime activities.

How to order?

An Order and inquiry for Aulone company should be accompanied by the following information.

Want to buy wire rope & sling?

We’re happy to assist you in finding the ideal rope for your application

86-15573139663

86-15363044363