UHMWPE (ULTRA HIGH MOLECULAR WEIGT POLYETHYLENE )

The AOMAX ROPE is made of ultrahigh molecular weight polyethylene fibre, which is interwoven with six strands each twisted in the direction of “S” and “Z”, so that the rope does not spin. The rope is hollow woven.The ultra high molecular weight polyethylene rope has the physical properties of high specific strength and high specific modulus. The specific strength is the same section of steel wire more than ten times, the specific modulus is second only to super carbon fiber.Secondly, its fiber density is low, the density is 0.97~0.98 grams/cubic centimeter, can float on the surface of the water.In addition, it has the advantages of low breaking elongation, large breaking power and strong ability to absorb energy, so it has outstanding impact resistance and cutting resistance.The rope made of ultra high molecular weight polyethylene is resistant to chemical corrosion, wear resistance and has a long flex ural life. It is widely used in Marine rescue, defense ships, shipbuilding industry, Marine operation survey, Marine geophysical exploration, ship mooring and other fields.

The wide use of ultra high molecular weight polyethylene rope:

Ultra high molecular weight polyethylene rope can be used in all directions because of its superior performance.

1. tow rope: high strength,light weight,easy to operate.

2. Heavy-duty rope used in Marine, fishing and coastal industries.Marine salvage systems, rescue systems, offshore oil platform systems, berthing, anchoring, embedded mooring lines, Marine seismic survey, submarine rope systems.

3.Yacht series: sail rope, foot line, halyard, sail rope, bowstring for shooting, etc.

4. Sports series: fishing line series, gliding line, parachute line, mountaineering line, sailing line, shooting bow string, etc.

5.military series: the navy with rope, sail rope, parachute troops with parachute and other sail rope, helicopter sling, rescue rope and army troops and armored forces with a variety of sail, maneuver with strong ropes, because of its strong high, small diameter, light weight, easy to carry and operation advantages,in many aspects suitable for use.

Main performance

| UHMWPE (Ultra High Molecular Weigt Polyethylene ) |

| Construction: 8 /12-strand etc |

| Application: ocean |

| Colour of Rope: White |

| Approx. Spec. Density 0.975 floating |

| Melting Point: 145℃ |

| Abrasion Resistance: Excellent |

| U.V.resistance: Good |

| Temperature resistance: 70℃ max |

| Chemical resistance: Excellent |

| Dry & wet conditions: Wet strength equals dry strength |

| Range of use: Fishing, off-shore installation, mooring |

| Coil length: 220m |

| Spliced strength: -10% |

| Weight and length tolerance: ±5% |

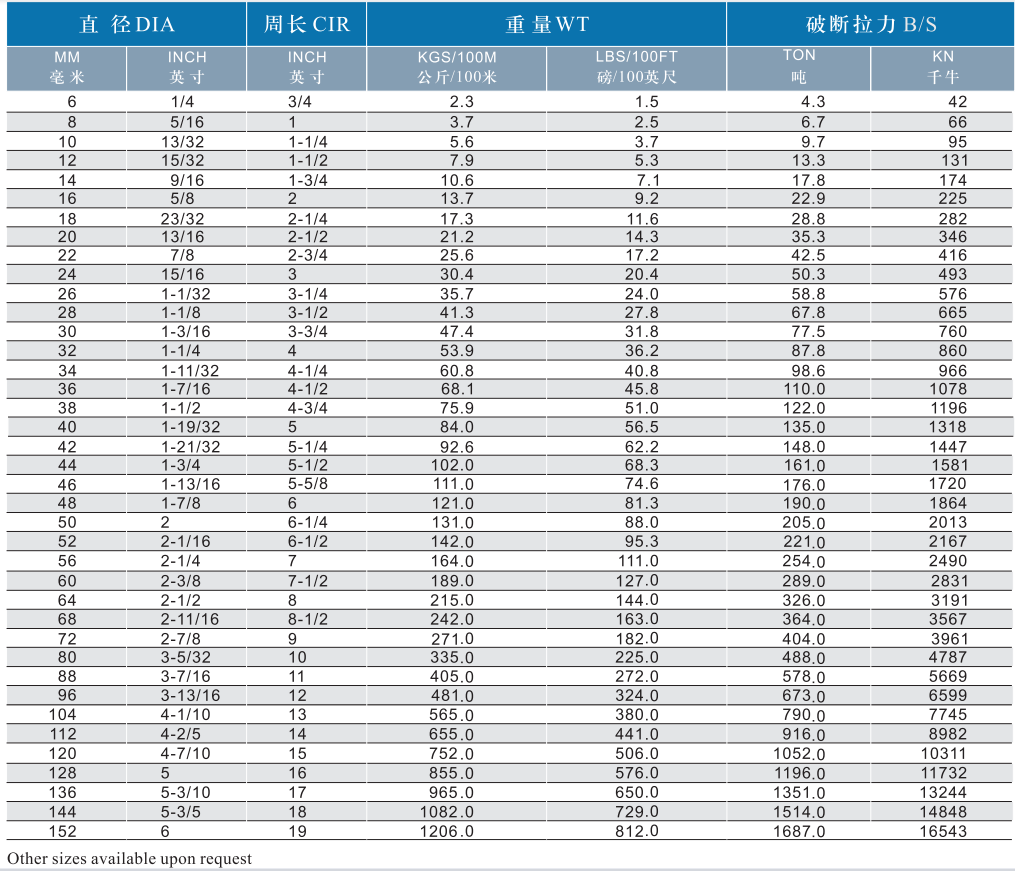

| MBL= Minimum Breaking Load conform ISO 2307 |

| Other sizes available upon request |

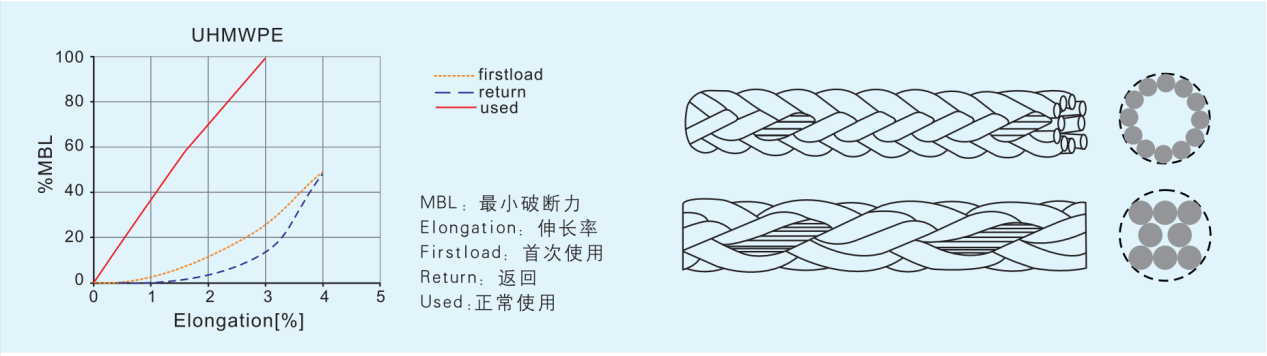

Technology Comparison

Parameter Table

Product picture