Are you confused about wire rope types? Choosing the right one is critical. Picking the wrong rope costs money and creates safety risks.

Bright wire rope is strong and affordable for dry, protected needs. Galvanized rope adds corrosion resistance. Stainless steel offers top rust protection for harsh environments.

Let me tell you about Andri. He always pushed for the best quality, but cost was a major concern. Finding the right balance for him was not easy, but we always managed it.

What Is Bright Wire Rope and When Should You Use It?

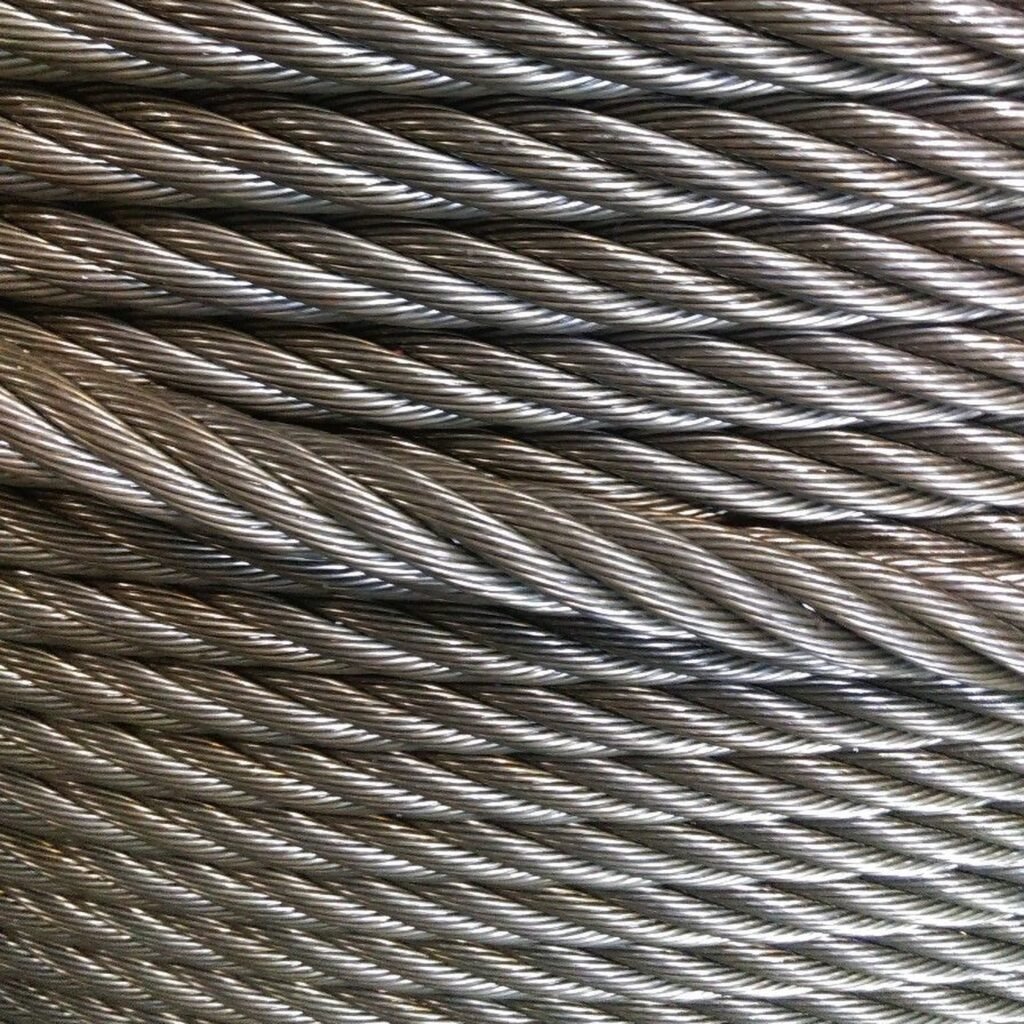

Bright wire rope is made from bare steel. It lacks any coating. This makes it strong and good for many jobs.

Bright wire rope is plain steel. It is strong. Use it indoors. Use it in dry places. It is for jobs without rust risk.

Dive Deeper: Bright Wire Rope’s Specifics

Bright wire rope is a basic option. It has high tensile strength. This means it can handle heavy loads well.

- Cost-effectiveness: Bright rope is often the cheapest. This saves money.

- Lubrication: It usually comes pre-lubricated. This reduces wear. It extends rope life.

- Indoor Use: Best for indoor lifting. Good for hoists or cranes in factories. Works for general rigging. Places where water is not present.

- Protection Needed: It will rust if exposed to moisture. Keep it dry.

| Property | Description |

|---|---|

| Material | Uncoated high-carbon steel |

| Appearance | Shiny, metallic silver |

| Corrosion Res. | Very Low |

| Strength | High tensile strength |

| Cost | Low |

| Typical Use | General industrial, indoor, protected areas |

Why Choose Galvanized Wire Rope for Outdoor or Wet Conditions?

Do your projects face rain or humidity? Bright wire rope will not last. Galvanized wire rope is a better choice.

Galvanized wire rope has a zinc coating. It fights rust. It is good for outdoor use. It works in damp places. It lasts longer than bright rope here.

Dive Deeper: The Benefits of Zinc Coating

Galvanized wire rope is steel with a zinc layer. This layer protects the steel. Zinc corrodes before the steel. This sacrificial protection saves the rope.

- Corrosion Resistance: The zinc coating protects against rust. It does well in rain. It also performs in humid air.

- Durability: It lasts longer than bright rope outdoors. This reduces replacement costs.

- Common Applications: Widely used for marine applications. Good for construction sites. Used in general outdoor rigging.

- Cost vs. Performance: It costs more than bright rope. But it offers much better protection. This makes it cost effective over time.

| Property | Description |

|---|---|

| Material | Steel core with zinc coating |

| Appearance | Dull gray |

| Corrosion Res. | Medium |

| Strength | High, but slightly less than bright of same size |

| Cost | Moderate |

| Typical Use | Outdoor use, marine, construction, damp environments |

When Is Stainless Steel Wire Rope the Ultimate Choice for Extreme Environments?

Are you dealing with salt water or harsh chemicals? Galvanized rope might not be enough. Stainless steel wire rope is the answer.

Stainless steel wire rope has chromium added. It provides excellent rust resistance. It is best for marine, chemical, or very corrosive places. It handles high temperatures too.

Dive Deeper: Stainless Steel’s Superiority

Stainless steel wire rope has high chromium content. This creates a passive layer on its surface. This layer prevents rust. It also resists other forms of corrosion.

- Maximum Corrosion Resistance: It stands up to salt water. It resists many chemicals. It does not rust in high humidity.

- Aesthetic Appeal: It keeps a bright, clean look. This is good for architectural rigging. It is also good for decorative uses.

- High Temperature Use: It performs well in hot conditions. It keeps its strength.

- Specialized Needs: Essential for marine environments. Good for chemical plants. Used in food processing facilities.

- Higher Cost: It is more expensive than galvanized. But its long life in harsh settings makes it worth it.

| Property | Description |

|---|---|

| Material | Steel alloy with chromium (e.g., 304, 316) |

| Appearance | Bright, shiny, clean |

| Corrosion Res. | Excellent (for salt, chemicals, high heat) |

| Strength | Good, but often lower than carbon steel |

| Cost | High |

| Typical Use | Marine, chemical plants, food processing, architecture |

How Do Breaking Load and Tensile Strength Differ Between Types?

Breaking load and tensile strength are key terms. They tell you about rope limits. Each rope type performs differently.

Breaking load is how much force breaks the rope. Tensile strength is the material’s internal stress limit. Bright rope often has highest tensile strength. Stainless steel is often lower.

Dive Deeper: Understanding Rope Performance

All wire ropes, regardless of type, are designed for heavy lifting. But their material properties affect performance.

- Bright Wire Rope: Generally offers the highest tensile strength. This means it can be made thinner for high loads. This makes it efficient. It is why it is common for lifting.

- Galvanized Wire Rope: The zinc coating adds some weight. It slightly reduces the effective steel cross-section. This can mean a tiny drop in breaking load compared to bare steel. But this loss is minimal. The rust protection gained is more important.

- Stainless Steel Wire Rope: Stainless steel alloys are designed for corrosion. They might have a lower tensile strength compared to plain carbon steel. So, for the same breaking load, a stainless steel rope might need to be slightly thicker. However, their specific grades (like 316) offer great resistance. They are good for their intended uses.

| Rope Type | Typical Breaking Load (Relative) | Notes |

|---|---|---|

| Bright | Highest for its size | Most direct strength from steel |

| Galvanized | Very High (slightly less than bright) | Zinc coating affects strength slightly |

| Stainless Steel | High (potentially lower than bright) | Strength optimized for corrosion resistance |

What Certifications and Customizations Are Available for Each Type?

Certifications prove quality. Customizations meet your specific needs. Knowing these options is important when buying.

We offer BV, CE, RMRS, DNV, ABS certificates. We comply with EN12385-4. Custom logos and plastic impregnation are available for some types. Galvanized options are also customizable.

Dive Deeper: Ensuring Quality and Fit

Certifications are crucial for safety. They show the rope meets strict standards. For example, EN12385-4 is important for general lifting.

- Quality Standards: We make our ropes to high quality. We ensure high breaking load. We also check for tensile strength. Our ropes comply with EN12385-4. This standard is for steel wire ropes for general lifting.

- Certification Importance: For Andri, certifications were always non-negotiable. He knew that without proper papers, his projects could not pass strict inspections. This is especially true for projects in critical infrastructure. Getting BV, CE, RMRS, DNV, or ABS certificates means our ropes are safe. They are reliable for many global uses.

- Custom Features:

- Customizable Logo: Yes, your brand logo can be added. This helps with branding.

- Plastic Impregnated: This is often done with bright or galvanized ropes. It adds lubrication. It protects the core. This helps extend life.

- Galvanized Option: This is a key customization. It adds rust protection. It is common for all rope constructions.

| Feature / Certification | Bright Rope | Galvanized Rope | Stainless Steel Rope |

|---|---|---|---|

| BV & CE | Yes | Yes | Yes |

| RMRS, DNV, ABS | Yes | Yes | Yes |

| EN12385-4 Compliant | Yes | Yes | Yes |

| Custom Logo | Yes | Yes | Yes |

| Plastic Impregnated | Yes | Yes | No |

| Galvanized Available | N/A | Yes | N/A |

Conclusion

Choosing the right wire rope depends on your project’s needs. Consider environment, strength, and budget. Each type offers distinct benefits.