Opening paragraph: Have you ever stared at a steel cable, wondering how to cut it? Trying to cut steel cables can be frustrating. Many people think bolt cutters are the answer.

Snippet paragraph: Bolt cutters can cut some steel cables. But it depends on the cable’s strength and thickness. Thicker, stronger cables are often too tough.

Transition paragraph: I remember a time on the factory floor. We needed to cut a specific cable. My team grabbed the bolt cutters first. Here’s what we learned then.

Are All Steel Cables the Same for Cutting?

Not all steel cables are alike. They come in many types. Each type has different properties.

No, steel cables differ in material, construction, and strength. These factors affect how easily you can cut them. Some are much harder to cut.

When we talk about cutting, understanding the cable is key. For example, some cables are galvanized. This means they have a zinc coating. This coating protects against rust. But it also adds a layer of hardness.

Think about tensile strength. This is how much pulling force a cable can handle before breaking. Cables with high tensile strength are very hard to cut. They are made for tough jobs. For instance, our crane wire ropes have very high tensile strength. This is why we need special tools for them.

Here is a simple breakdown:

| Cable Type | Materials | Typical Use | Cutting Difficulty |

|---|---|---|---|

| Galvanized Wire Rope | Carbon Steel, Zinc | General purpose, outdoors | Medium |

| Stainless Steel Wire Rope | Stainless Steel | Marine, corrosive environments | High |

| Crane Wire Rope | High-Carbon Steel | Lifting heavy loads | Very High |

| Synthetic Rope | Nylon, Polyester | Mooring, light lifting | Low |

We also need to consider the cable’s construction. Some cables have many small wires twisted together. This makes them flexible. Others have fewer, thicker wires. This makes them stiffer and stronger. Both affect how a cutting tool performs.

For instance, our factory makes specialized assemblies. These often use cables with specific constructions. This design makes them super strong. So, bolt cutters are just not enough. We use hydraulic cutters for these.

What Are Bolt Cutters Made For?

Opening paragraph for h2: Bolt cutters look strong. They seem like they can cut anything. But they have specific uses.

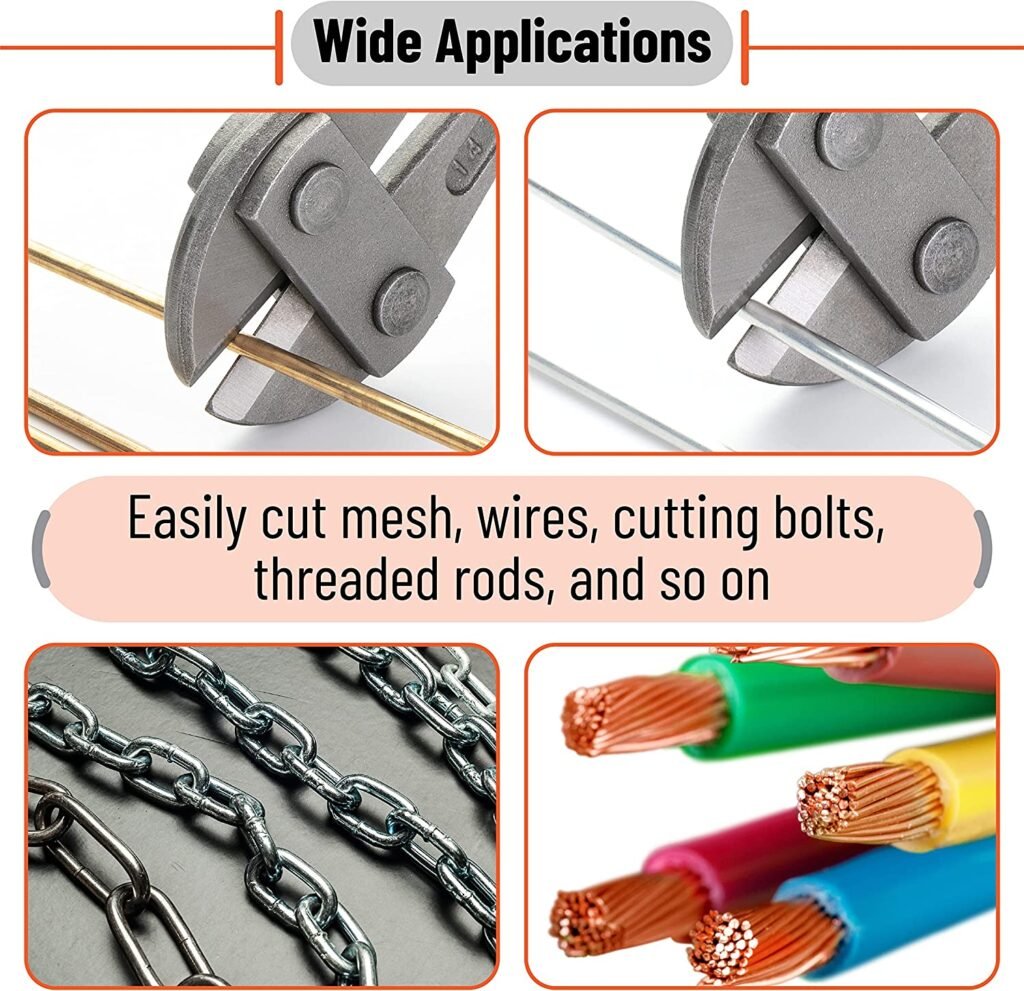

Bolt cutters are designed to cut soft or medium-hard metals. They excel at cutting bolts, chains, and padlocks. They are not made for high-strength steel.

Bolt cutters work by leverage. You apply force to the long handles. This force gets magnified at the short jaws. This allows them to cut through materials. But there’s a limit.

The jaws of bolt cutters are usually made from hardened steel. But high-strength steel cables are even harder. Trying to cut them can damage the bolt cutter blades. I have seen blades chip. This makes the tool useless.

Here’s a look at what bolt cutters are typically used for:

- Bolts and Rods: Up to a certain diameter.

- Chains: Small to medium links.

- Padlocks: Shackles depending on their hardness.

- Fencing Wire: Common for farm use.

When we deal with our wire ropes, especially for mining or elevators, their breaking load is very high. Bolt cutters simply cannot handle that. Their blades would deform or break. We need tools that apply massive pressure.

What Tools Should You Use to Cut Steel Cable?

Opening paragraph for h2: Don’t just grab bolt cutters. Choosing the right tool is vital. It keeps you safe. It also gets the job done right.

Snippet paragraph for h2: You should use tools like hydraulic cutters, angle grinders, or specific wire rope cutters. These tools are designed for the hardness and structure of steel cables.

At Aulone, we use different tools for different cables. Safety is always our top priority. The wrong tool can lead to serious injury.

Here are the tools we recommend and use:

- Hydraulic Cutters: These are very powerful. They use hydraulic pressure to sever thick cables. We use these for our larger diameter crane wire ropes. They make clean cuts.

- Angle Grinders: An angle grinder with a metal cutting disc can cut steel cables. It creates a lot of sparks. You must wear safety glasses and gloves. This method is effective for galvanized wire ropes.

- Cable Cutters (Dedicated): These are specialized hand tools. They have curved blades. They grip the cable and make a clean cut. They are good for smaller diameter wire ropes. We use these for elevator wire ropes. It stops the cable from fraying.

- Oxy-Acetylene Torches: These use a flame to melt through the metal. They are good for very thick cables. But they require special training and safety measures.

Andri, a buyer from Australia, once asked about cutting tools. He has critical quality control. I explained that using the right tool ensures a clean cut. A clean cut is important for installation and safety. It prevents fraying. Fraying can lead to early failure of the rope.

Here is a quick comparison of suitable tools:

| Tool Type | Suited For | Advantages | Disadvantages |

|---|---|---|---|

| Hydraulic Cutters | Thick, high-tensile cables | Powerful, clean cuts | Expensive, needs power source |

| Angle Grinders | Various steel cables | Versatile, accessible | Sparks, heat, safety concerns |

| Dedicated Cable Cutters | Smaller diameter wire ropes | Clean cuts, portable | Limited to smaller diameters |

| Oxy-Acetylene Torch | Very thick cables | Cuts almost anything | High heat, safety, requires skill |

Choosing the right tool also prevents damage to the cable. A bad cut can weaken the cable. This reduces its breaking load. We always aim for perfect cuts. This ensures our products meet high quality standards like EN12385-4.

Conclusion

Bolt cutters are not for every steel cable. They work for some, but not all. Always use the right tool. This ensures safety and a successful cut.