Does your wire rope look rusty? Rust can cause big problems. It makes ropes weaker and unsafe. You need to fix it.

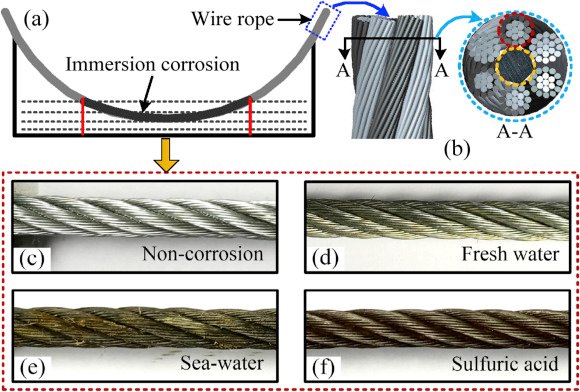

Wire rope corrosion is metal breakdown caused by environment. It lowers strength and safety. Prevention needs proper lubrication and storage.

I remember a time when a new client, quite particular about quality, almost walked away. Their previous supplier had issues. This made me understand that small issues like a tiny bit of rust can lead to very big problems.

What causes wire rope to corrode?

Wire ropes often corrode due to many factors. These include water, chemicals, and air. Moisture is a common cause. Saltwater is very corrosive.

Wire rope corrosion often happens when moisture, chemicals, or salt attack the metal. This breaks down the steel over time.

Corrosion is a big problem for wire ropes. It harms their strength. It makes them break down. This happens in many ways.

Exposure to Moisture

Water is a major enemy. Rain, humidity, or even damp air can cause rust. This happens especially in marine settings. Think of ropes on ships or oil rigs. They are always wet. This makes them rust much faster.

Chemical Exposure

Chemicals also cause damage. Acids and bases can eat away at the metal. This applies to ropes used in industrial plants. They might touch harsh cleaning agents. Or they could be near chemical spills. This quickens corrosion.

Lack of Lubrication

Proper lubrication protects ropes. It creates a barrier. This barrier keeps out moisture and chemicals. Without it, the metal is open to attack. Old grease dries out. It then cracks. This lets water in.

Environmental Factors

Air pollution plays a part. Industrial areas have more sulfur dioxide. This gas can react with moisture. It forms sulfuric acid. This acid then attacks the rope. Extreme temperatures also cause issues. Hot and cold cycles lead to condensation. This brings moisture in.

Improper Storage

Storing ropes incorrectly causes damage. Leaving them on wet ground is bad. Storing them outside in the rain is worse. They should be in a dry, clean place. They need to be off the ground. This prevents moisture buildup.

Material Quality

The type of steel matters. Low-quality steel corrodes faster. It has more impurities. Better steel, like stainless steel, resists rust more. But even the best material can corrode without care.

What are the dangers of corroded wire ropes?

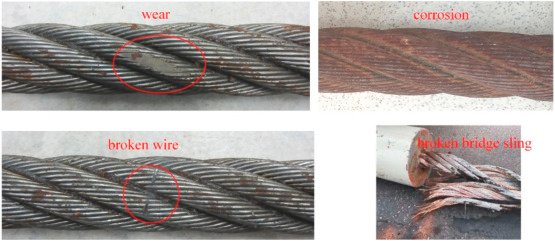

Corroded wire ropes are very dangerous. They can break without warning. This causes risks to people. It also damages property.

Corroded wire ropes are a high risk for failure. They lose strength, leading to sudden breaks. This can cause severe accidents and injuries.

When wire ropes corrode, they lose their strength. This means they cannot lift as much. They can snap suddenly. This can harm people and equipment.

Reduced Breaking Strength

Corrosion reduces the rope’s breaking load. The metal inside gets weaker. This means the rope can fail under less weight. This is very risky in heavy lifting.

Increased Risk of Failure

A corroded rope can break without signs. Rust hides other problems. You cannot see frayed wires. This makes inspection hard. A sudden break can cause crashes. It can hurt workers. It can destroy property.

Shortened Lifespan

Corrosion shortens the rope’s life. Ropes need replacement more often. This causes higher costs. It means more downtime for machines. This is bad for business.

Hidden Damage

Rust often starts inside the rope. You cannot see it from the outside. The outer wires might look fine. But inner wires could be very weak. This makes it a silent danger.

Operational Downtime

When a rope fails, work stops. Machines cannot run. This stops production. It means lost money. It takes time to replace the rope. It takes time to check what went wrong.

Safety Violations and Fines

Using corroded ropes is a safety violation. Companies can face big fines. They can get legal trouble. This harms their reputation. It can lead to severe penalties.

How can I prevent wire rope corrosion effectively?

Preventing wire rope corrosion is crucial. It saves money. It keeps workers safe. You need to use the right methods.

To prevent wire rope corrosion, keep it clean and lubricated. Store it properly. Choose suitable materials for the environment.

Preventing corrosion is not hard. It needs constant care. Here are some key ways to prevent it.

Regular Cleaning and Inspection

Clean ropes remove dirt and chemicals. Use a brush to clean them. Then wipe them down. Inspect them often. Look for rust, broken wires, or kinks. Early detection helps.

Proper Lubrication

Lubrication is key. Use a good wire rope lubricant. Apply it regularly. This coats the wires. It fills inner spaces. It keeps moisture out. It reduces friction. Make sure to use the right type of lubricant for your environment.

Optimized Storage Conditions

Store ropes in a dry place. Keep them off the ground. Use reels or pallets. Protect them from weather. Cover them if stored outside. Keep them away from chemicals.

Material Choice

Choose the right rope material. For harsh environments, use galvanized ropes. Or choose stainless steel ropes. Galvanized ropes have a zinc coating. This layer protects against rust. Stainless steel resists corrosion better. But it costs more. It is good for very wet or salty places.

Environmental Controls

Try to control the environment. Use dehumidifiers in storage areas. If possible, avoid chemicals near ropes. This reduces risks.

Training and Awareness

Train your staff. Make sure they know about corrosion. They need to know how to inspect ropes. They need to know how to maintain them. This helps prevent problems.

What is the best way to choose a high-quality wire rope?

Choosing a high-quality wire rope is vital. It impacts safety and performance. You need to know what to look for.

The best way to choose high-quality wire rope is to check its breaking strength, material quality, and compliance with standards. Look for certifications.

Selecting the right wire rope is not simple. You need to consider several factors. A good choice ensures safety and lasts longer.

Understand Your Needs

First, know what you need the rope for. What is the load? What environment will it be in? Will it be wet or dry? Will it be hot or cold? This helps you pick the right type.

Check Material and Construction

Look at the material. Is it carbon steel or stainless steel? For rust resistance, stainless steel or galvanized ropes are better. Check the rope construction. Different constructions (e.g., 6×19, 6×37) offer different strengths and flexibility.

Verify Breaking Strength

High breaking strength is key. This means the rope can handle more weight. Always check the supplier’s data. Compare it with your lifting needs. Make sure it has a safe working load.

Look for Certifications

Certifications show quality. They mean the rope meets specific standards. For example, our ropes comply with EN12385-4. We also provide BV & CE, RMRS, DNV, and ABS certificates. These ensure the rope meets safety and performance rules.

Supplier Reputation

Choose a trusted supplier. A good supplier has experience. They provide good customer service. They offer product support. Check their history and reviews.

Customization Options

Sometimes you need custom ropes. Look for suppliers who can customize. We offer customizable logos. This flexibility helps meet specific project needs.

Consider Plastic Impregnation

For extra protection, consider plastic impregnated ropes. These have plastic filling the spaces between wires. This keeps moisture out. It prevents internal corrosion. It also reduces wear.

Conclusion

Wire rope corrosion is serious. It weakens ropes and creates risks. Prevent it with proper care and materials.