Are you struggling to pick the right wire rope? Choosing the wrong lay direction can cause big problems. You need to get this right for safety and performance.

You must match the rope’s lay direction to your drum and sheave grooves. This stops rotation and wear. Most often, a regular lay rope is the correct choice.

I remember one time a client picked the wrong rope. The machine vibrated and wore down fast. It caused costly delays. Let me show you how to avoid that.

Should my crane wire rope be right regular lay or left regular lay?

Picking the right rope lay is critical. It makes sure your crane works well. An incorrect lay can cause serious issues.

For most cranes, a regular lay rope is best. This means the strands twist opposite to the wires. Right regular lay is very common for overhead cranes.

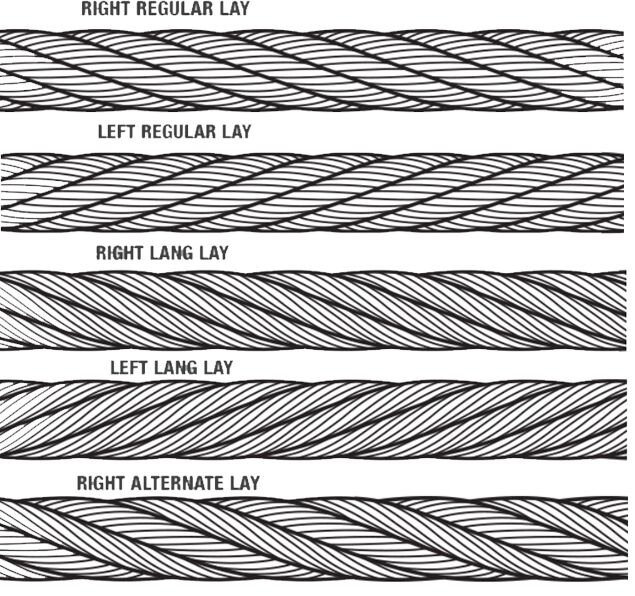

Let’s look deeper at rope lay. There are a few types to consider. Understanding them helps you make good choices.

What are the main types of wire rope lay?

The way wires and strands are twisted defines the lay. This greatly affects rope behavior. Here are the common types:

| Lay Type | Wire Twist | Strand Twist | Characteristics |

|---|---|---|---|

| Regular Lay | Z-lay | S-lay | Wires and strands twist in opposite directions. |

| Lang Lay | Z-lay | Z-lay | Wires and strands twist in the same direction. |

| Right Lay (RH) | Clockwise | Clockwise | Strands move up and to the right. |

| Left Lay (LH) | Counter-clockwise | Counter-clockwise | Strands move up and to the left. |

How does ‘lay’ affect rope performance?

Lay direction impacts how the rope handles and wears. A regular lay rope is stable. It resists rotation well. This is good for lifting. Lang lay ropes are more flexible. They resist abrasion better. But, they can untwist if not properly secured. Choosing depends on your specific needs. My team always helps clients understand these differences. We ship many high-quality ropes. They go to places like Singapore and Canada. We ensure the right fit.

What is the difference between right lay and left lay for wire rope?

The difference is simple. It’s about the twist direction. This matters for how the rope winds. It also affects how the rope works with your equipment.

Right lay rope twists clockwise. Left lay rope twists counter-clockwise. You must match this to your drum grooving. This keeps the rope winding smoothly.

The rope must sit well in the grooves. If it does not, you will see problems. Wear will increase. Safety can be put at risk.

Why does drum grooving affect the lay direction I choose?

Drum grooves guide the rope. They make sure the rope winds evenly. If your drum has right-hand grooves, you often need right lay rope. If it has left-hand grooves, you need left lay rope. This simple match prevents overlap and crushing. It helps your rope last longer. I always tell my clients to check their drum first. It saves trouble later.

Can I use a regular lay wire rope in all hoisting applications?

Regular lay ropes are versatile. They are used in many hoisting tasks. They offer good balance. They have fair flexibility and good stability. This makes them a strong choice. However, some specific applications might need different types. For example, some multi-part line systems might need rotation-resistant ropes. This prevents twisting. We can provide full technical support. We make sure our ropes meet EN12385-4. We also offer BV and CE certificates.

What are the benefits of choosing the correct lay direction for my wire rope?

Choosing the correct lay direction has many benefits. It is not just about performance. It also greatly affects safety and cost.

The correct lay direction ensures stable operation. It reduces wear and extends rope life. It also greatly improves overall safety on site.

Failure to do this can lead to serious issues. I have seen machinery fail because of wrong rope selection. It is a costly mistake.

How does the correct lay direction improve rope life and safety?

When the lay direction is correct, the rope sits properly. It moves smoothly over sheaves and drums. This reduces friction. Less friction means less wear. Less wear means your rope lasts much longer. It also means less chance of sudden failure. A safe workplace is critical. Our ropes have high tensile strength. They have high breaking loads. This provides extra safety margin.

What happens if I use the wrong lay direction for my mine hoisting wire rope?

Using the wrong lay direction can cause big problems. The rope will not spool properly. It can rub against itself. It might also rub against drum flanges. This leads to rapid wear. It can cause twisting or kinking. These issues lead to premature rope failure. This can be very dangerous. It can also shut down your operations. This means big financial losses. My Australian client, Andri, always stressed strict quality control. He knows the importance of getting these details right.

Conclusion

Choosing the right wire rope lay direction is very important. It ensures smooth operation. It extends rope life. It also keeps your operations safe.