Opening paragraph: Is your crane hoist struggling? Do you need a lifting solution that you can trust? Poor quality wire ropes can cause serious problems for your operations.

Snippet paragraph: A wire rope crane hoist uses a powerful motor to reel a steel wire rope around a drum. This simple yet effective system lifts and lowers heavy loads safely.

Transition paragraph: I remember a time when a client had constant issues with their old hoist. It wasn’t just about the machine. It was about how the wire rope worked with it.

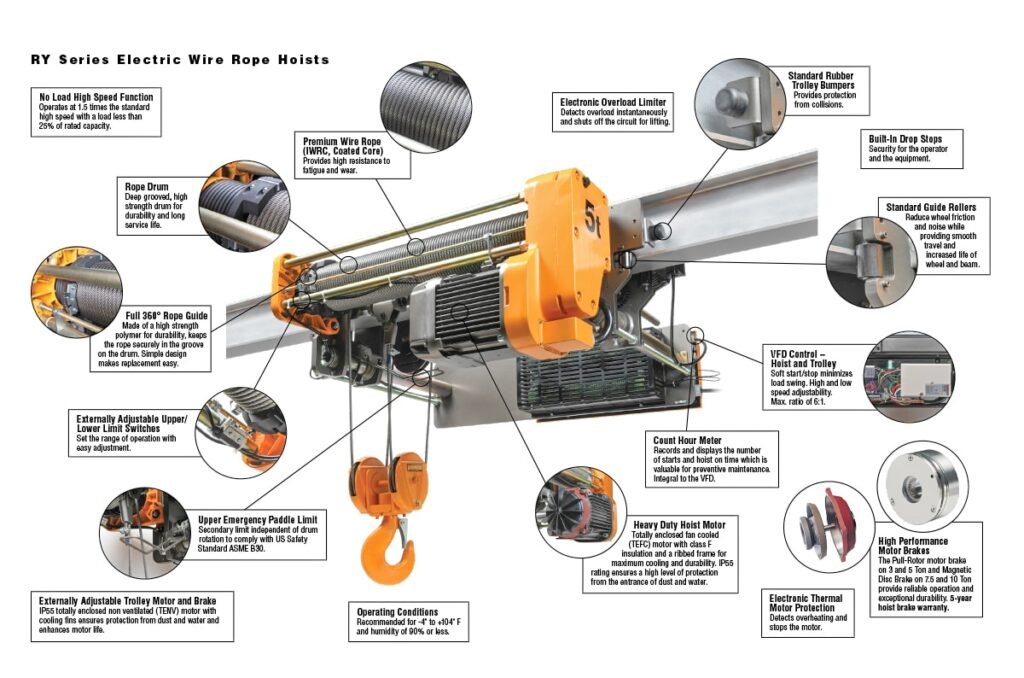

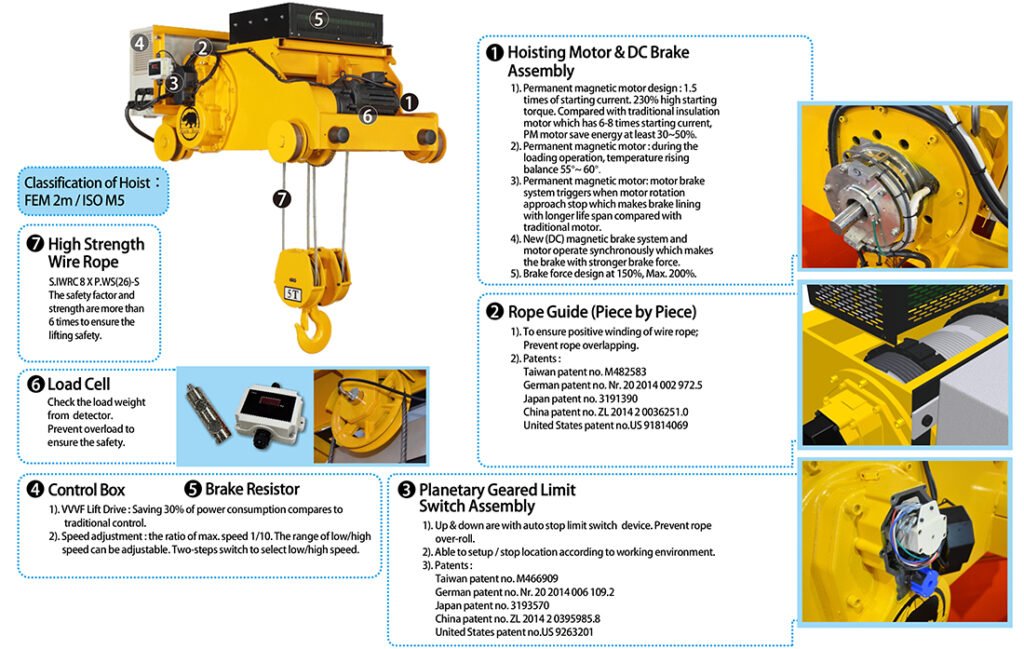

What are the key components of a wire rope hoist?

Do you know what makes a wire rope hoist work? Understanding each part is important for safe and strong lifting.

A wire rope hoist has several key parts. These include the drum, the motor, the gearbox, the brakes, and the wire rope itself. Each part plays a vital role.

Let’s look closer at each part.

The Wire Rope Drum

The drum is like a reel. It winds up and unwinds the wire rope. Its size is important. A larger drum reduces stress on the rope. This helps the rope last longer. My factory uses strong steel for our drums. This ensures they can handle heavy work.

The Electric Motor

The motor provides the power. It turns the drum. Different hoists need different motor sizes. A strong motor helps lift heavy things easily. We make sure our motors are matched to the hoist’s lifting capacity. This ensures good performance.

The Gearbox System

The gearbox connects the motor to the drum. Gears change the motor’s speed and power. This allows the hoist to lift very heavy objects. My team designs gearboxes for smooth and efficient operation. This means less wear and tear.

The Braking System

Brakes are for safety. They stop the load from falling. There are often two types of brakes. These include an electric brake and a mechanical brake. Both work together to hold the load in place. We strictly follow safety standards. This ensures our brakes are reliable.

The Wire Rope Itself

The wire rope is the lifting tool. It is made of many strong steel wires. These wires are twisted together. This makes a very strong rope. My company specializes in high-quality wire ropes. We make them with high tensile strength. They have a high breaking load. This high breaking load means they can lift much more than their rated capacity. This provides an extra layer of safety. We also make sure they follow EN12385-4 standards. This ensures quality.

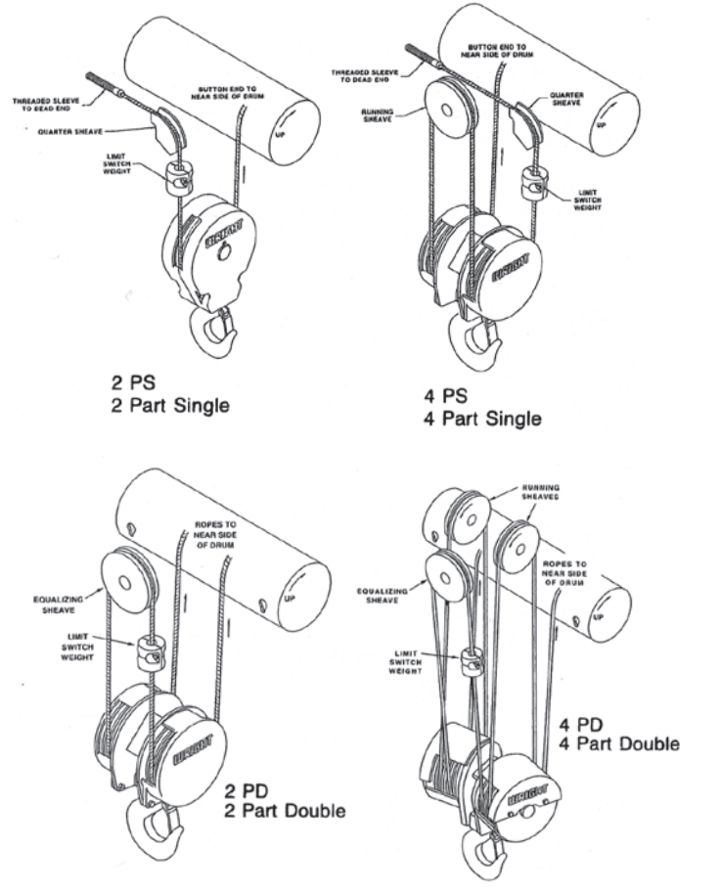

How does the wire rope interact with the hoist?

Opening paragraph for h2: Have you ever wondered why the wire rope is so important? Its connection to the hoist is key for safe lifting.

The wire rope wraps around the hoist drum. The motor powers the drum to wind or unwind the rope. This action lifts or lowers the hook and its load. The rope’s strength determines how much the hoist can lift.

The wire rope is the direct link to the load. It bears all the weight. We need to understand how this works.

Rope Structure and Strength

My factory makes wire ropes with different structures. Each structure offers different benefits. For example, some ropes are made for flexibility. Others are made for more strength. We use specific grades of steel. This makes our ropes very strong. Our ropes also have a high breaking load. This means they can handle extreme pressure.

How the Rope Winds on the Drum

The rope winds onto the drum in a specific pattern. Grooves on the drum guide the rope. This helps the rope wind evenly. Even winding prevents tangles. It also helps the rope last longer. If the rope winds unevenly, it can cause damage. We design our hoists to ensure smooth winding.

The Importance of Rope Tension

The wire rope needs proper tension. Too much slack can be dangerous. It can cause the rope to jump off the drum. Too much tension can damage the rope and hoist. Regular checks are important. This ensures correct tension. My team trains clients on how to check this.

Customized Wire Ropes for Hoists

We can customize wire ropes. We offer plastic impregnated ropes. These ropes have plastic inside. This makes them more durable. We also offer galvanized ropes. Galvanized ropes have a zinc coating. This protects them from rust. We can even add your logo. This is useful for distributors.

What safety features are built into wire rope hoists?

\Are you concerned about safety? Wire rope hoists have several features to keep workers safe.

Snippet paragraph for h2: Wire rope hoists include many safety features. These include overload protection, limit switches, and emergency stop buttons. These features prevent accidents and protect the equipment.

Safety is always our top priority. Here are some key safety features.

Overload Protection

This system prevents lifting too much weight. If the load is too heavy, the hoist will not lift it. This protects the hoist motor and rope from damage. It also prevents the crane from tipping. I always advise my clients to respect the hoist’s load limit.

Limit Switches

Limit switches control movement. They stop the hoist at the top and bottom of its travel. This prevents the hook from hitting the hoist body. It also stops the hook from unwinding too much rope. These small devices make a big difference in safety.

Emergency Stop Button

This button stops all hoist movement immediately. Workers can use it in an emergency. It is usually big and red. Everyone should know where it is. This is a very basic but important safety feature.

Certification and Standards

We make sure our products meet international standards. We can provide BV, CE, RMRS, DNV, and ABS certificates. These certificates show our products are tested and safe. For example, our wire ropes meet EN12385-4. This means they are made to high quality specifications. This gives customers peace of mind.

How do you maintain a wire rope crane hoist?

Do you want your hoist to last longer? Proper maintenance is key to keeping it running well.

Regular maintenance for a wire rope hoist includes checking the wire rope for wear. You also need to inspect the drum, motor, and brakes. Lubrication and timely repairs are also very important for its long life.

Regular checks prevent problems. Here are some maintenance tips.

Wire Rope Inspection

Always check the wire rope. Look for signs of wear. Look for broken wires or rust. Look for kinks or flattened parts. If you see damage, replace the rope. My factory makes durable ropes. But even the best ropes need checking.

Lubrication

Lubrication keeps parts moving smoothly. It reduces friction. This lowers wear. Make sure to lubricate the gearbox and bearings. Also, some wire ropes benefit from external lubrication. This can extend their life.

Brake Checks

Test the brakes often. Make sure they stop the load quickly. Check for any unusual sounds. If the brakes feel weak, get them serviced. Faulty brakes are a major safety risk.

Electrical System Checks

Check all electrical connections. Look for loose wires. Make sure all switches work. A stable electrical supply is important for the motor. Problems here can cause the hoist to fail.

Regular Servicing Schedule

It is best to have a planned service schedule. This means checking the hoist at regular times. For example, weekly, monthly, or yearly. This helps find problems early. Early fixes save money and prevent bigger issues. My company can guide you on the best schedule for your hoist.

Conclusion

Wire rope crane hoists are complex machines. They rely on many parts working together. Understanding each part helps ensure safe and efficient lifting. Regular maintenance is crucial for long-term use.