Have you ever considered what makes a wire rope so dependable? How does it hold up in extreme conditions? The truth is, quality starts from the very beginning of its making.

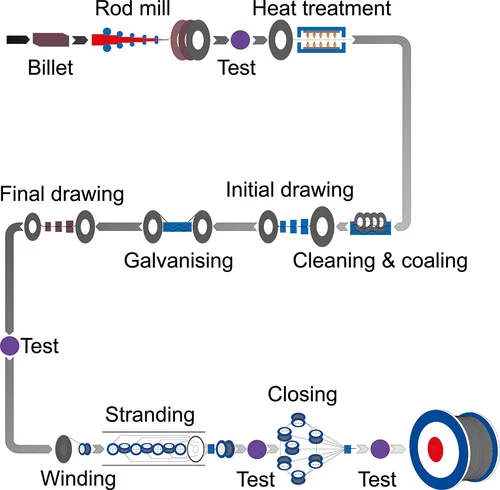

Wire rope is a complex product, meticulously crafted from high-quality steel wires. We draw these wires, then twist them into strands, and finally lay these strands around a central core to form the finished rope, ensuring high strength and reliability.

When I first started in this business, I was fascinated by the art and science behind wire rope. It’s more than just metal; it’s a careful dance of precision and strength. From raw materials to the final product, every step is crucial. Let me explain.

What Materials Go Into Our Wire Rope?

Before we can twist anything, we need the right foundation. This means starting with high-quality materials. It is the first step in our process.

We use only premium, high-carbon steel rods as our base material. This choice is crucial because it gives the initial high tensile strength needed. This material then goes through a cleaning and drawing process.

1. Raw Material Preparation

Material Selection

- Steel rods are the primary raw material. These are typically:

- High-carbon steel (for strength and wear resistance)

- Stainless steel (for corrosion resistance)

- Galvanized steel (zinc-coated for added rust protection)

- Alloy steel (e.g., with chromium, molybdenum for specialty ropes)

2. Wire Drawing

Goal: Reduce large-diameter steel rods (usually 5.5–6.5 mm) to fine-diameter wires used in rope strands.

Process

- Pickling: Rods are passed through acid to remove surface scale and rust.

- Coating: Sometimes a layer of lime or borax is applied to assist the drawing process.

- Drawing: Rods are pulled through a series of progressively smaller tungsten carbide or diamond dies.

- Example: A rod might go from 5.5 mm → 2.0 mm → 1.0 mm → 0.3 mm in successive dies.

Heat Treatments (Optional)

- Annealing: Softens the wire, improves ductility.

- Patenting: Controlled heating and cooling to refine microstructure, increasing fatigue resistance.

- Galvanizing: Zinc coating applied by hot-dip or electroplating for corrosion resistance.

3. Stranding – Building the Strands

Goal: Twist individual wires together to form strands.

Structure Patterns

Different configurations affect strength, flexibility, and abrasion resistance. Common strand designs include:

Seale

- Large outer wires, fewer layers.

- Good abrasion resistance.

- Warrington

- Alternating large and small wires in the outer layer.

- More flexible.

Filler Wire

- Small wires fill gaps between large wires.

- Increases strand diameter while improving support.

Warrington-Seale (WS)

- Hybrid pattern – balances flexibility and wear resistance.

- Used in hoist ropes, cranes, elevators.

Stranding Machine

- Twists wires around a central core wire (king wire).

- Strands like 1+6, 1+6+12, etc., are common.

- Example: 6×K36WS means 6 strands, each made of 36 wires in a K-style (Warrington-Seale).

4. Closing – Assembling the Rope

Goal: Twist strands around a core to form the finished rope.

Core Types

| Core Type | Description | Usage |

|---|---|---|

| Fiber Core (FC) | Natural or synthetic fiber | Flexible, but lower strength |

| Steel Core (WSC) | One steel strand as core | Good strength, moderate flexibility |

| Independent Wire Rope Core (IWRC) | A small wire rope used as core | High strength and crush resistance |

➿ Lay Direction

- Right Lay (Z) or Left Lay (S) – direction of strand twist.

- Regular Lay: Strands and wires twisted in opposite directions.

- More stable, less prone to untwisting.

- Lang Lay: Strands and wires twisted in the same direction.

- More flexible, but less stable.

5. Optional: Pre-forming

What is it?

- Each wire or strand is pre-bent into its final helical shape before assembly.

Benefits

- Prevents wires from springing out if cut.

- Helps maintain rope shape under load.

- Essential in high-performance and non-rotating ropes.

6. Optional: Compaction

Why?

- Compresses strands or the whole rope to reduce outer diameter and increase contact area.

Types

- Strand compacted: Individual strands compressed before closing.

- Rope compacted: Rope is compressed after closing (with dies or rollers).

Advantages

- Higher breaking load (up to 20% more).

- Smoother surface.

- Lower internal wear.

7. Lubrication

Purpose

- Reduces internal wear.

- Protects against corrosion.

Methods

- During manufacture: Grease injected during closing.

- Post-manufacture: Surface sprayed or dipped.

- Types of lubricants:

- Mineral oils, synthetic grease, dry lubricants, or food-grade oils (for food industry ropes).

8. Plastic Insertion / Coating (EPIWRC, PPI, PVC-coated ropes)

Internal Plastic Layer (EPIWRC)

- A plastic layer is extruded between core and outer strands.

- Prevents internal wear, corrosion.

- Used in offshore, marine, and rotary drilling applications.

External Coating

- Some ropes are fully coated with PVC or nylon for aesthetic or corrosion reasons.

9. Quality Control & Testing

Routine Checks

- Diameter measurement

- Tensile strength

- Elongation at break

- Wire ductility (bend test)

- Zinc coating thickness (if galvanized)

- Fatigue life (bend over sheave test)

Certificates

- ISO, API, DNV, ABS, CCS, Lloyd’s, etc., depending on usage.

- Third-party inspection often required in critical industries like oil & gas, mining, and shipbuilding.

10. Final Finishing & Packaging

Steps

- Rope is cut to required length.

- End fittings (thimbles, sockets) may be applied.

- Rope is coiled on reels, drums, or steel spools.

- Tags include:

- Rope type

- Construction

- Breaking load

- Manufacturer info

- Date of production

- Traceability batch number

Summary Table

| Step | Description |

|---|---|

| 1 | Steel rod preparation |

| 2 | Drawing wires through dies |

| 3 | Stranding wires into strands |

| 4 | Closing strands into rope with a core |

| 5 | Optional pre-forming for shape memory |

| 6 | Optional compacting for strength |

| 7 | Lubrication for corrosion & wear |

| 8 | Plastic insertion for high-performance use |

| 9 | Testing for strength and quality |

| 10 | Packaging & labeling |