Does your project need a specific wire rope? Choosing the wrong one can cause big problems. It can lead to safety risks and project delays.

Choosing the right wire rope requires thinking about factors like strength, material, and environment. You also need to know its intended use.

I’ve spent years working with wire ropes. I’ve seen projects succeed and fail because of wire rope choices. Let me share what I’ve learned.

What Factors Should You Consider When Selecting Wire Rope?

Do you know what makes a wire rope right for a job? It’s more than just thickness. You must think about many things.

When selecting wire rope, consider its breaking strength, material type, resistance to corrosion, and flexibility needs. The environment it will be used in also matters.

When I work with clients, these are the first things we talk about. They have high standards. They need exact matches for their projects. We look at the load the rope will carry. We check the temperature and moisture where it will operate. We discuss if it touches chemicals. All these details influence the choice.

Breaking Strength and Working Load Limit

The breaking strength is how much force the rope can take before it breaks. The working load limit (WLL) is a fraction of this. It ensures safety. Always choose a rope with a WLL much higher than your expected load.

Material Composition

Wire ropes are often made from carbon steel or stainless steel. Carbon steel is strong. Stainless steel resists rust. Galvanized carbon steel has a coating for rust resistance. Plastic impregnated ropes offer extra protection.

Environmental Conditions

If the rope will be exposed to water, salt, or chemicals, you need a special kind. Marine wire ropes are designed for sea environments. Galvanized wire ropes are good for outdoor use.

Flexibility and Construction

Rope construction counts. It affects how flexible the rope is. A 6×19 construction is common. It balances strength and flexibility. A 6×36 much more flexible. The application tells you what flexibility you need.

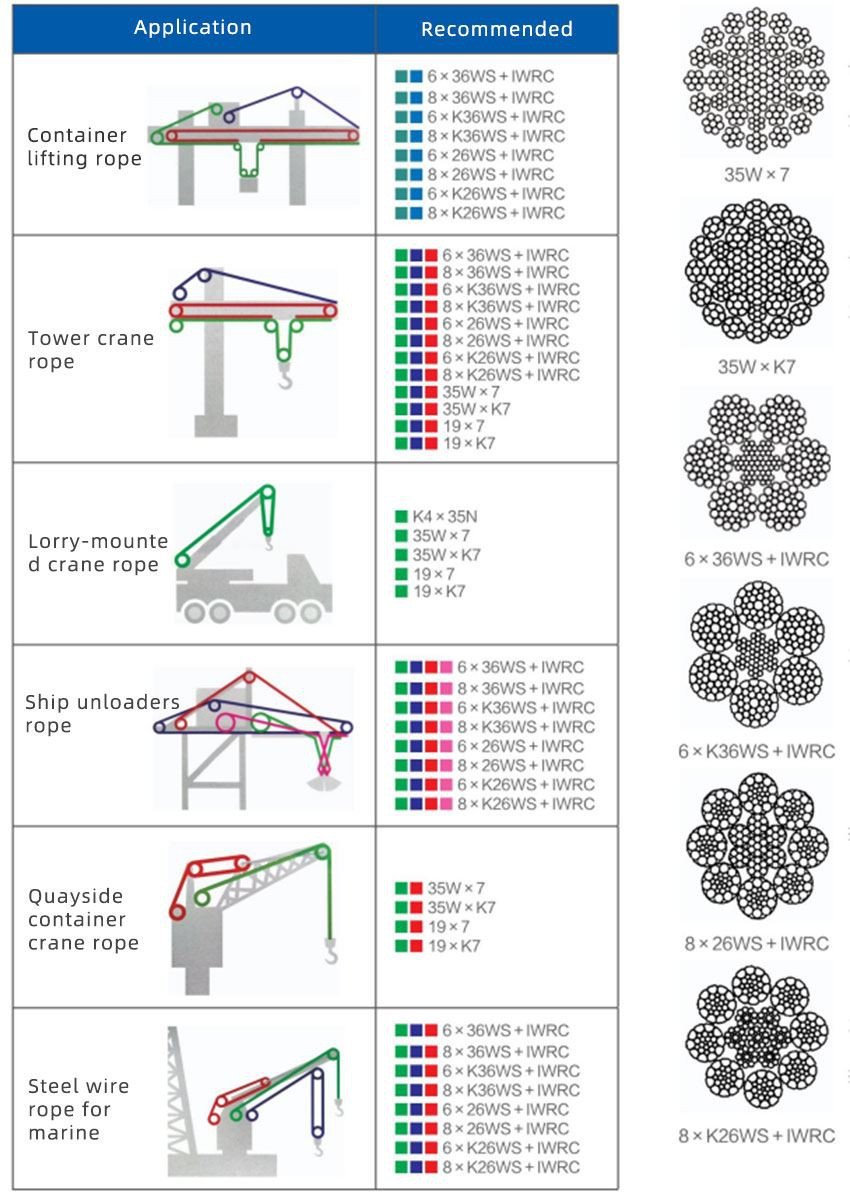

What Are the Different Types of Wire Ropes and Their Uses?

Are you aware of the different types of wire ropes? Each one serves a unique purpose. Knowing them helps you pick the best fit.

Wire ropes vary in type, including general purpose, crane, elevator, mining, galvanized, marine, synthetic, and stainless steel ropes. Each is designed for specific applications and environments.

At Aulone, we produce a wide range. I often explain these differences to customers. For example, a crane needs a very strong rope. An elevator needs one built for smooth, vertical movement. Each plays a critical role.

General Purpose Wire Ropes

These are versatile. They are used in many common lifting situations. They balance strength and flexibility.

| Type | Common Uses | Key Features |

|---|---|---|

| 6×19 | General lifting, rigging | Good balance of flexibility and wear |

| 6×36 | Crane hoist, logging | More flexible, good for bending |

Crane Wire Ropes

These are built for heavy lifting. They have high breaking loads. They are crucial for safety in construction. They are central to many industrial operations. They need to meet strict safety standards.

Elevator Wire Ropes

These ropes prioritize smooth movement and safety. They are designed for cyclic loading. They must have good fatigue resistance. They ensure passenger safety.

Mining Wire Ropes

Mining operations are tough. These ropes must withstand extreme conditions. They are resistant to abrasion and heavy loads. They are vital for moving materials and equipment underground.

Galvanized Wire Ropes

These ropes are coated with zinc. This coating protects against rust. They are excellent for outdoor use. They are good in wet or humid places.

Marine Wire Ropes

Marine ropes face harsh saltwater. They often use stainless steel or special coatings. They resist corrosion. They are used on ships, docks, and underwater.

Synthetic Ropes

These ropes are lighter than steel. They can be very strong. They are often used when weight is a concern. They are also non-conductive.

Stainless Steel Wire Ropes

Stainless steel wire ropes are highly resistant to rust. They are good for corrosive environments. They are also used where appearance matters.

Specialized Assemblies

Sometimes, a standard rope isn’t enough. We make custom assemblies. These have special fittings. They meet unique project needs.

Why is Quality and Certification Important for Wire Ropes?

Are you sure about the quality of your wire rope? Low quality can cause accidents. It can lead to project failure. High quality is not just a choice, it is a must.

Quality and certification are crucial for wire ropes as they ensure safety, reliability, and compliance with industry standards. High-quality ropes reduce risks and save costs long-term.

Many of my clients ask about certifications. They want to know if they meet EN12385-4. At Aulone, we provide many certificates. We offer BV, CE, RMRS, DNV, and ABS. These certificates prove our quality. They show our ropes meet global standards. We focus on high tensile strength and high breaking load. This means our ropes are strong. They are reliable.

Compliance with Standards

Following standards like EN12385-4 ensures ropes are made to perform. It means they pass critical tests. This gives you peace of mind.

| Standard | Description | Importance for Wire Rope |

|---|---|---|

| EN12385-4 | Steel wire ropes for general lifting purposes | Ensures safety and performance in lifting |

| ISO 2408 | Steel wire ropes – Characteristics and testing | Provides global guidelines for quality and testing |

| DNV GL (DNV) | Maritime classification society | Certifies ropes for marine and offshore use |

| American Bureau of Shipping (ABS) | Marine and offshore classification society | Ensures ropes meet standards for shipbuilding |

| Russian Maritime Register of Shipping (RMRS) | Russian classification society for ships | Required for vessels operating under Russian flag |

High Tensile Strength and Breaking Load

These are key indicators of a rope’s strength. High values mean the rope can handle heavy loads. This prevents early failure.

Certifications and Traceability

Certificates show that the rope meets specific standards. Traceability allows you to track its origin and production data. This is important for quality control. It helps in auditing.

Customizable Options

We offer customized options. You can get ropes with a custom logo. You can choose plastic impregnated or galvanized finishes. These options meet specific project needs. They help with branding too.

What Are the Benefits of Partnering with a Reliable Wire Rope Manufacturer?

Are you getting the service you deserve from your wire rope supplier? A good partner helps you succeed. A bad one can cause big delays.

Partnering with a reliable wire rope manufacturer ensures high-quality products, consistent supply, expert support, and adherence to delivery schedules. It results in reduced risks and better project outcomes.

Many clients look for a long-term partner. They care about pricing. They care a lot about consistent quality. They need their orders delivered on time. My company, Aulone, has four production lines. This means we can handle big orders. We ship to many countries. These include Singapore, Indonesia, and Australia. We work hard to meet customer needs. This builds trust. We make sure our ropes comply with international standards.

Consistent Supply and Production Capacity

A reliable manufacturer has strong production. This means they can meet your demands. This prevents delays in your projects. Our four production lines help us do this.

Expert Technical Support

Good manufacturers offer technical advice. They help you choose the right rope. They solve problems. They understand complex projects.

Competitive Pricing and Payment Terms

Finding a balance between cost and quality is vital. A reputable manufacturer offers fair prices. They also provide flexible payment terms. We offer 30% T/T in advance. The rest is paid against the B/L copy.

Global Export and Logistics

A manufacturer with global reach makes shipping easy. They understand customs. They ensure timely delivery. We export to over ten countries. This includes Canada and the UAE.

Conclusion

Choosing the right wire rope is crucial for safety and success. Consider strength, material, and environment carefully. Always pick a certified, high-quality product from a reliable partner like Aulone.