Are you uneasy about your wire ropes? Do you worry about their reliability? Wire rope safety is critical. It directly impacts your work efficiency and people’s lives.

To ensure wire rope safety, you must conduct regular inspections, store them correctly, and operate them properly. Choose high-quality, compliant products.

I once saw an accident happen due to neglected wire rope safety. I was on an overseas project. A team used a worn-out wire rope. The heavy object almost fell. This made me realize how important safety is, no matter how small the detail.

Why Is Choosing the Right Wire Rope Crucial for Safety?

Choosing the correct wire rope is fundamental for safety. The wrong type or material can lead to disastrous outcomes. A suitable product ensures safe and stable operations every time.

Choosing the right wire rope is crucial for safety. It directly impacts load capacity, wear resistance, and environmental suitability. This prevents safety risks from mismatches.

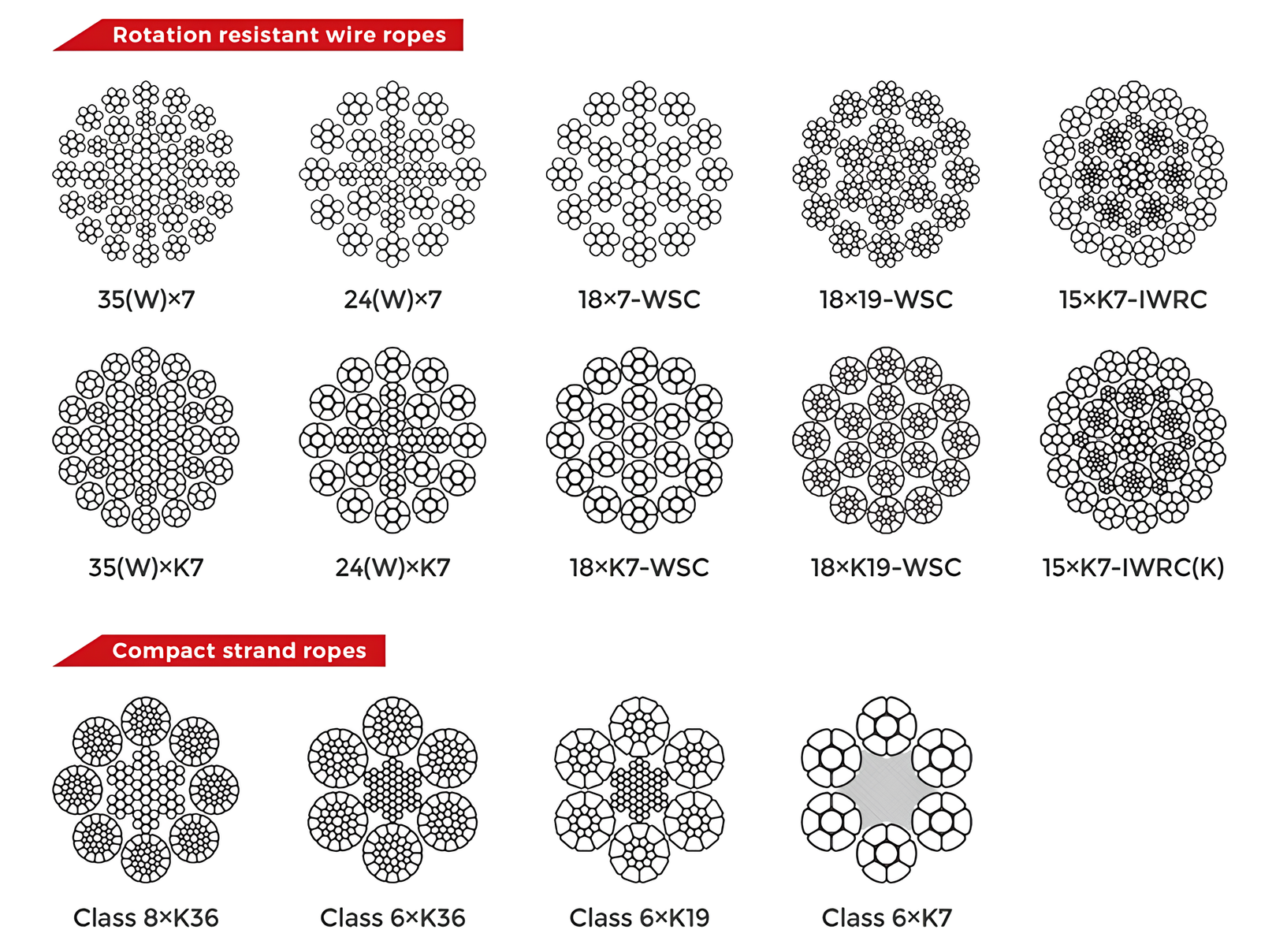

Different Wire Rope Types and Their Applications

Each wire rope type has a specific design purpose.

For instance, hoisting wire ropes need high strength. They also need excellent fatigue resistance.

Mining wire ropes require extreme wear resistance.

Marine wire ropes need strong corrosion resistance.

| Type | Typical Applications | Characteristics |

|---|---|---|

| 6×19 | General lifting, slings | Good flexibility, wide use |

| 6×36 | Heavy lifting, construction | High breaking load, strong compression resistance |

| 8×19 | Elevators, precision equipment | Better flexibility, smooth operation |

| 18×7 | Non-rotational needs, multi-layer drums | Non-rotating, reduces tangling |

Material and Environmental Adaptability

The material of a wire rope also determines its suitable environment.

Galvanized wire ropes are suitable for wet or corrosive environments.

Stainless steel wire ropes are used in marine or medical fields.

Regular carbon steel wire ropes are for dry environments.

The Importance of Standards and Certifications

Wire ropes compliant with international standards like EN12385-4 have undergone strict testing.

These standards ensure the product’s quality and performance.

All our Aulone products strictly follow these standards.

We can also provide BV, CE, and RSRM certifications.

This offers customers additional quality assurance.

How Should Daily Inspection and Maintenance of Wire Ropes Be Performed?

Daily inspection is key to preventing accidents. Regular maintenance extends wire rope life. Neglecting an inspection can turn small issues into major failures.

Daily inspection should focus on wear, broken wires, deformation, and corrosion. Proper maintenance includes regular cleaning, lubrication, and correct storage to ensure performance.

Key Areas and Signs to Look for During Inspection

During inspection, you need to pay special attention to several critical wire rope parts.

For example, check for broken strands. This is the most common wear.

Changes in wire rope diameter are also important.

If the diameter decreases, it may mean internal corrosion or looseness.

The end connections are points of maximum stress. They need careful checking.

If there are kinks, distortions, or bird caging, the wire rope is damaged.

The Necessity of Lubrication and Cleaning

Lubrication reduces internal friction within the wire rope.

This helps prevent wear and corrosion.

Cleaning removes surface dust and debris.

These impurities can accelerate wear.

Choosing the right lubricant is also important.

Different wire ropes require different lubricants.

At Aulone, we can advise you based on your needs.

When Is It Time to Replace Wire Ropes?

Knowing when to replace a wire rope is vital.

When the number of broken wires exceeds the specified limit, replacement is mandatory.

For example, if more than a certain number of broken wires per strand.

If the wire rope diameter significantly reduces, it also needs replacement.

Severe corrosion or deformation also warrants replacement.

These signs indicate the wire rope is no longer safe.

Do not risk using a defective wire rope.

How to Properly Store and Transport Wire Ropes to Preserve Their Performance?

Correct storage and transport methods effectively protect wire ropes. Improper storage can lead to premature aging. Proper transport ensures products arrive in good condition.

Properly store wire ropes in a dry, ventilated area, free from corrosive substances. During transport, prevent severe shocks and tangles. Ensure the wire rope is not crushed or contaminated to maintain its initial performance.

Requirements for Storage Environment

The ideal storage environment should be dry.

Good indoor ventilation is also important.

Avoid direct sunlight and high humidity.

These factors accelerate wire rope corrosion.

The storage area should be away from chemicals or corrosive gases.

These substances can corrode the wires.

Store wire ropes coiled on pallets.

Avoid direct contact with the ground.

Precautions During Transportation

When transporting wire ropes, prevent severe impacts.

Impacts can cause wire rope deformation.

Use appropriate supports and securing devices.

Ensure the wire rope remains stable during transport.

Avoid contact between the wire rope and sharp objects.

Sharp objects can scratch or damage the strands.

If transporting large reels, use specialized equipment.

Ensure safe loading and unloading processes.

Norms for Packaging and Marking

Wire ropes are professionally packaged upon leaving the factory.

For example, they use moisture-proof materials and wooden reels.

This packaging protects the wire rope from external environmental factors.

The packaging will have clear markings.

Markings include wire rope specifications, length, and production date.

This information is crucial for both storage and use.

It helps you quickly identify and manage inventory.

Conclusion

Ensuring wire rope safety involves selecting the right products, performing daily checks and maintenance, and proper storage and transport. These steps guarantee safe operations and improve efficiency.