Plastic Coated Wire Rope

High-Performance Wire Ropes and Sling Solutions

High-performance plastic-coated wire ropes are designed to offer superior strength, durability, and resistance to harsh conditions, making them ideal for demanding applications. These ropes are manufactured using advanced materials and specialized techniques to meet the highest standards of performance.

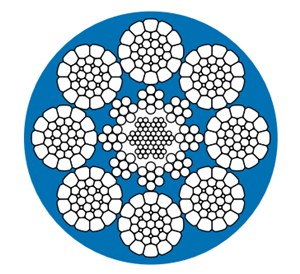

EP6XK36WS-IWRC

Our Advantage

- Good resistance to fatigue

- Plastic polymer cushions strands, distributes internal stresses and keeps out dirt.

- 6-strand & compacted.

- Good abrasion resistance.

- Keeps lubricant in, allowing internal movement between wires and strands.

- Superior abrasion resistance.

- Reduced coefficient of friction between rope and overburden

- Improved performance.

- Keeps lubricant in, allowing internal movement between wires and strands.

lt is recommended to RHLL lay types, excellent wear resistance and impact resistance, especially suitable for iron rope single rope winding operation, reducing contact stress with the wheeltrain.

Typical structure: 6xK36WS-IWRC, 6XK36WS-EPIWRC, EP6XK36WS-IWRC, 6xK41WS-IWRC, 6XK41WS- EPIWRC,EP6xK41WS-IWRC,6x K49WS-IWRC, 6xK49WS-EPIWRC, EP6xK49WS-IWRC.

Application: WK, P & H, EKG, BE series electric shovel main hoisting wire rope for open-pit coal mine,iron ore, copper ore, construction and other mining

| Diameter | Approx. | Tensile strength (MPa) | ||

| (mm) | weight | 1770 | 1960 | 2160 |

| (kg/100m) | Minimum breaking load (kN) | |||

| 52 | 1200 | 1814 | 2009 | 2214 |

| 53 | 1248 | 1888 | 2090 | 2303 |

| 54 | 1298 | 1962 | 2173 | 2395 |

| 55 | 1348 | 2038 | 2257 | 2488 |

| 56 | 1400 | 2116 | 2343 | 2582 |

| 57 | 1452 | 2195 | 2431 | 2679 |

| 58 | 1505 | 2276 | 2520 | 2777 |

| 59 | 1560 | 2358 | 2611 | 2877 |

| 60 | 1615 | 2441 | 2703 | 2979 |

| 61 | 1671 | 2526 | 2797 | 3083 |

| 62 | 1728 | 2613 | 2893 | 3188 |

| 63 | 1786 | 2700 | 2990 | 3295 |

| 64 | 1845 | 2790 | 3089 | 3404 |

| 65 | 1905 | 2880 | 3189 | 3515 |

| 66 | 1966 | 2972 | 3292 | 3627 |

| 67 | 2028 | 3066 | 3395 | 3742 |

| 68 | 2091 | 3161 | 3500 | 3858 |

| 69 | 2155 | 3258 | 3607 | 3975 |

| 70 | 2220 | 3356 | 3716 | 4095 |

| 71 | 2285 | 3455 | 3826 | 4216 |

| 72 | 2352 | 3556 | 3938 | 4339 |

| 73 | 2420 | 3658 | 4051 | 4464 |

| 74 | 2488 | 3762 | 4166 | 4591 |

| 75 | 2558 | 3867 | 4282 | 4719 |

| 76 | 2628 | 3974 | 4401 | 4850 |

| 77 | 2700 | 4082 | 4520 | 4982 |

| 78 | 2772 | 4192 | 4642 | 5115 |

| 79 | 2846 | 4303 | 4765 | 5251 |

| 80 | 2920 | 4415 | 4889 | 5388 |

EP8XK36WS-IWRC

Our Advantage

- Good resistance to fatigue

- Plastic polymer cushions strands, distributes internal stresses and keeps out dirt

- Proprietary 8-strand construction

- Good abrasion resistance

- Keeps lubricant in, allowing internal movement between wires and strands

- Superior abrasion resistance

- Reduced coefficient of friction between rope and overburden

- Improved performance

- Keeps lubricant in, allowing internal movement between wires and strands

Application: They can be used as Variable amplitude rope on mobile crane, vessel crane and grab bucket crane. And can be used as hoisting rope on container crane, floating crane, portal crane and steel factory crane etc… Also be applicable to multi-multiplying power system with smaller hoisting height, double coiling block system with matched left-hand and right-hand pairs using for deep hoisting height.

The EP8XK36WS-IWRC wire ropes are the most fatigue-resistant ropes we offer for shovel hoist applications, offering benefits such as maximum service for longer digging times between rope changes.

Rope series : 8×K31WS, 8×K36WS, 8×K41WS

In accordance with the EN 12385-4 standard.

Core:IWRC, Independent Wire Rope Core

Grade:1770mpa,1960mpa,2160mpa

| Diameter | Approx. | Tensile strength (MPa) | ||

| (mm) | weight | 1770 | 1960 | 2160 |

| (kg/100m) | Minimum breaking load (kN) | |||

| 52 | 1275 | 1814 | 2009 | 2214 |

| 53 | 1327 | 1888 | 2090 | 2303 |

| 54 | 1379 | 1962 | 2173 | 2395 |

| 55 | 1433 | 2038 | 2257 | 2488 |

| 56 | 1487 | 2116 | 2343 | 2582 |

| 57 | 1543 | 2195 | 2431 | 2679 |

| 58 | 1599 | 2276 | 2520 | 2777 |

| 59 | 1657 | 2358 | 2611 | 2877 |

| 60 | 1716 | 2441 | 2703 | 2979 |

| 61 | 1775 | 2526 | 2797 | 3083 |

| 62 | 1836 | 2613 | 2893 | 3188 |

| 63 | 1898 | 2700 | 2990 | 3295 |

| 64 | 1960 | 2790 | 3089 | 3404 |

| 65 | 2024 | 2880 | 3189 | 3515 |

| 66 | 2089 | 2972 | 3292 | 3627 |

| 67 | 2155 | 3066 | 3395 | 3742 |

| 68 | 2222 | 3161 | 3500 | 3858 |

| 69 | 2289 | 3258 | 3607 | 3975 |

| 70 | 2358 | 3356 | 3716 | 4095 |

| 71 | 2428 | 3455 | 3826 | 4216 |

| 72 | 2499 | 3556 | 3938 | 4339 |

| 73 | 2571 | 3658 | 4051 | 4464 |

| 74 | 2644 | 3762 | 4166 | 4591 |

| 75 | 2718 | 3867 | 4282 | 4719 |

| 76 | 2793 | 3974 | 4401 | 4850 |

| 77 | 2869 | 4082 | 4520 | 4982 |

| 78 | 2946 | 4192 | 4642 | 5115 |

| 79 | 3024 | 4303 | 4765 | 5251 |

| 80 | 3103 | 4415 | 4889 | 5388 |

Your Ultimate Guide to Acquiring Plastic Coated Wire Rope

Acquiring plastic-coated wire rope requires attention to specific factors to ensure you select a product that meets your needs in terms of durability, flexibility, and corrosion resistance. Plastic coating provides an extra layer of protection to the wire rope, making it suitable for various applications where environmental conditions may cause wear and corrosion. Here’s your ultimate guide to acquiring plastic-coated wire rope:

Table of contents

Chapt 1

What is Plastic Coated Wire Rope?

Plastic-coated wire rope, also known as PVC-coated wire rope, involves a steel wire rope encased in a plastic (typically PVC or polyurethane) sheath. This coating provides several benefits:

Protection Against Corrosion: The plastic layer helps protect the metal wire from environmental factors like moisture, chemicals, and salt, which can lead to corrosion.

Increased Durability: The coating also helps to reduce wear and tear on the rope, making it last longer, especially in harsh or abrasive environments.

Reduced Friction: The smooth surface of the plastic can decrease the amount of friction between the wire rope and the pulleys or guides it runs through, which can enhance the lifespan of both the rope and the equipment.

Noise Reduction: Plastic-coated wire ropes tend to operate more quietly than uncoated ropes, which can be beneficial in noise-sensitive areas.

Aesthetic and Visibility: The coating can be produced in various colors for aesthetic purposes or to enhance visibility for safety reasons.

This type of wire rope is widely used in various applications, including fitness equipment, marine environments, architectural structures, and wherever additional protection for the wire rope and/or the surrounding environment is required.

Chapt 2

Advantege of Plastic Coated Wire Rope

Plastic-coated wire rope offers several advantages compared to uncoated wire rope:

Corrosion Resistance: The plastic coating provides a protective barrier against moisture, chemicals, and other corrosive substances, extending the lifespan of the wire rope, especially in outdoor or marine environments.

Abrasion Resistance: The plastic coating helps to reduce friction and wear on the wire rope, increasing its durability, particularly when used in applications where it comes into contact with rough surfaces or edges.

Flexibility: The plastic coating can enhance the flexibility of the wire rope, making it easier to handle and manipulate, as well as reducing the risk of kinking or bending damage.

Noise Reduction: Plastic-coated wire rope tends to operate more quietly than uncoated wire rope, making it suitable for applications where noise levels need to be minimized.

Improved Grip: The smooth surface of the plastic coating can provide a better grip, making it easier to handle the wire rope and reducing the risk of slippage, especially when used in lifting or towing applications.

Aesthetic Options: Plastic-coated wire rope is available in a variety of colors, allowing for customization to match specific aesthetic requirements or to enhance visibility for safety purposes.

Versatility: Plastic-coated wire rope can be used in a wide range of applications, including marine, architectural, industrial, and recreational settings, thanks to its durability and resistance to environmental factors.

Easy Identification: The plastic coating can be color-coded or labeled with identifying information, making it easier to distinguish between different types or sizes of wire rope and simplifying inventory management and maintenance.

Chapt 3

Plastic Coated Wire Rope Production Procedure

Manufacturing

Auxiliary materials select raw material selection

(1) Choose high -quality wire rod

High Quality Raw Material

Wire Rod Grade : 72A, 82B

Performance of the wire rod: strength, organization

(2) Select German Lube

Oil drop point Drop Point: > 110 ° C

Britty Point: <-53 ℃

Auxiliary material selection

Imported brand for plastic use of injection molding

Tensile strength: ≥27.4

Hardness: 55D

Low temperature performance: -60 ℃

Fragmentation elongation: ≥ 550%

Wire Drawing

Steel wire drawing using in the domestic more common direct type large diameter wire drawing mechanism, our company through research and test and verification, the use of unique wire drawing process, the production of steel wire torsion, bending indicators are 20% higher than the standard, strength loss and dispersion is small, steel wire residual stress elimination is complete, good performance

Strand & Rope Closing

Our tubular & planet strand & rope closing machine can cover variety of wire rope products

These applications benefit from the compacted wire rope’s enhanced properties, such as increased load-bearing capacity, improved flexibility, reduced internal friction, and superior resistance to fatigue and environmental damage.

Chapt 4

Quality Assurance For Plastic Coated Wire Rope

Quality assurance for plastic-coated wire rope is crucial to ensure that the product is safe, durable, and performs as expected under various conditions. Here are the key steps involved in the quality assurance process:

Raw Material Inspection: The first step in quality assurance involves inspecting the raw materials, including the steel wire and plastic coating material (e.g., PVC, polyurethane). These materials should meet specific industry standards and quality criteria to ensure the final product’s strength and durability.

Manufacturing Process Control: Throughout the manufacturing process, parameters such as temperature, speed, and coating thickness are closely monitored. Consistency in these parameters is essential to ensure that the wire rope is coated evenly and the plastic adheres properly to the steel wire.

Coating Thickness Measurement: The thickness of the plastic coating is a critical parameter. It is measured using micrometers or specialized coating thickness gauges to ensure that it falls within specified tolerance levels. Adequate coating thickness is essential for optimal protection and performance.

Adhesion Test: The adhesion of the plastic coating to the wire rope is tested to ensure that the coating will not peel off or crack under normal usage conditions. This can be tested through methods such as pull tests or peel tests.

Visual Inspection: The coated wire rope is visually inspected for any defects such as bubbles, uneven coating, or impurities. Visual inspection is a straightforward but effective method to catch obvious defects.

Dimensional Checks: The diameter and length of the wire rope are checked to ensure they meet the specified dimensions. This is important for applications where precise sizing is critical.

Load Testing: Load tests are conducted to ensure the wire rope can handle the specified maximum load without failing. This test is crucial for applications involving lifting or bearing heavy loads.

Corrosion Resistance Testing: For applications where corrosion resistance is critical, the wire rope may undergo accelerated aging processes to simulate exposure to corrosive environments. Tests may include salt spray tests to assess how well the coating protects against corrosion.

Flexibility and Fatigue Testing: The plastic-coated wire rope is tested for flexibility and fatigue resistance, especially for dynamic applications where the wire rope will be moving or bending repeatedly.

Certification and Compliance: Finally, the wire rope should meet or exceed all relevant standards and regulations, such as those from ASTM, ISO, or specific industry standards. Certification documents and compliance reports are prepared to accompany the product for end-users.

Quality assurance is integral at every step, from the selection of raw materials through manufacturing to final inspection, ensuring the plastic-coated wire rope is reliable and safe for its intended use.

Get the catalogue

Leave a request and we will send you the catalogue with Aulone steel wire ropes by e-mail

86-15573139663

86-15363044363