Plastic impregnated Wire Rope

Aulone Plastic impregnated wire rope offers a versatile solution for various industries and applications, providing enhanced durability, corrosion resistance, and performance in challenging environments

Custom Wire Ropes for Advanced Engineering Solutions

The right materials make all the difference in engineering projects. Utilizing our high-strength, top-quality plastic impregnated Wire Rope for Advanced Engineering Solutions ensures optimal performance and longevity. Aulone specializes in producing customized wire ropes tailored to a variety of industrial needs, ensuring safety and efficiency in operations such as mining, transportation, and construction.

Explore the Aulone difference with our customized wire ropes, crafted to meet your exact specifications in length, configuration, and strength. Trust in our extensive experience to deliver solutions that exceed your engineering requireme

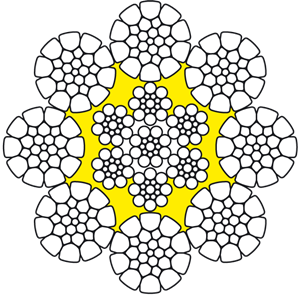

Typical Structure

35WXK7-EPIWRC

- High polymer filled and sealed steel reinforced plastic layer within the lubricating oil to make it longer.

- Resistance to outer strands of wire rope to squeeze;

- Non-rotation Recommended for high lifting operations

- High strength

- Reduced rope sheave wear

- Accurate diameter,recommended for multi-layer coiling

- Suitable for single part and multi-part reeving Long service life

Multistrand Non-rotating Wire Ropes with Compacted Outer Strands, EN 12385-4

Diameter | Approx. weight (kg/100m) | Tensile strength (MPa) | ||

(mm) | 1770 | 1960 | 2160 | |

Minimum breaking load (kN) | ||||

8 | 33 | 51 | 56 | 62 |

9 | 41 | 65 | 71 | 79 |

10 | 51 | 80 | 88 | 97 |

11 | 62 | 96 | 107 | 118 |

12 | 73 | 115 | 127 | 140 |

13 | 86 | 135 | 149 | 164 |

14 | 100 | 156 | 173 | 191 |

15 | 115 | 179 | 198 | 219 |

16 | 131 | 204 | 226 | 249 |

17 | 147 | 230 | 255 | 281 |

18 | 165 | 258 | 286 | 315 |

19 | 184 | 288 | 318 | 351 |

20 | 204 | 319 | 353 | 389 |

21 | 225 | 351 | 389 | 429 |

22 | 247 | 386 | 427 | 470 |

23 | 270 | 421 | 467 | 514 |

24 | 294 | 459 | 508 | 560 |

25 | 319 | 498 | 551 | 608 |

26 | 345 | 538 | 596 | 657 |

27 | 372 | 581 | 643 | 709 |

28 | 400 | 624 | 691 | 762 |

29 | 429 | 670 | 742 | 817 |

30 | 459 | 717 | 794 | 875 |

31 | 490 | 765 | 848 | 934 |

32 | 522 | 816 | 903 | 995 |

35 | 625 | 976 | 1080 | 1191 |

36 | 661 | 1032 | 1143 | 1260 |

39 | 776 | 1211 | 1342 | 1478 |

40 | 816 | 1274 | 1411 | 1555 |

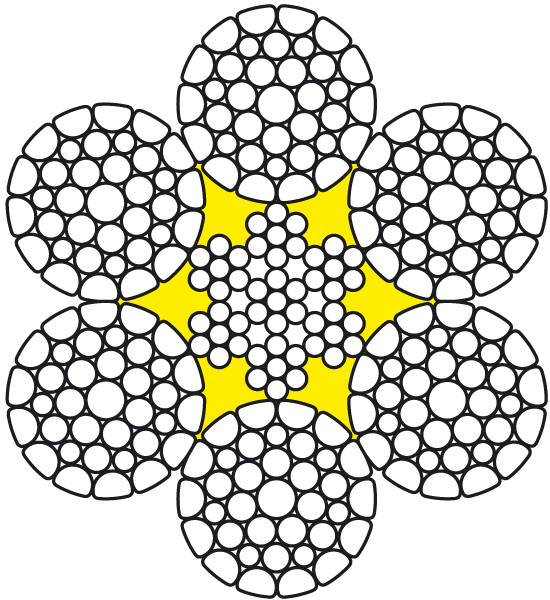

8XK26WS-EPIWRC

- High breaking force

- lexible eight strand construction

- High temperature lubricant

- Consistent performance

- Enhanced bend fatigue

- Superior crush resistance

- Accurate diameter tolerance

- Long life, reduced lifetime costs

- Reduced stretch

- Corrosion protected core

- Recommended for multi-layer coiling

Since steel wire ropes are used under extreme conditions both in building construction and in civil engineering, operational safety and reliability play an important role. 8XK26WS-EPIWRC from Aulone combines reliability and operational safety due to its excellent all-round characteristics.

Reliability and operational safety due to the high durability of the rope at very high minimum breaking forces;

Long service life due to the wear-optimized design and the plastic insert protecting the core;

Excellent spooling characteristics in multilayer spooling due to high dimensional stability under lateral pressure;

Low wear achieved by compaction of all strands allows a perfect use in scraper installations. compaction technology which ensures high breaking forces and maximum safety in use.

Its compacted inner core and a plastic insert give the rope high dimensional stability under lateral pressure.

Rope series :8×K19S, 8×K26WS, 8×K31WS, 8×K36WS, 8×K41WS

In accordance with the EN 12385-4 standard.

Different constructions depending on the diameter.

Core:IWRC, Independent Wire Rope Core

Grade:1770mpa,1960mpa,2160mpa

Lay: sZ,zS,zZ,sS

8XK26WS-EPIWRC is a high performance compacted single layer constructed rope which incorporates a plastic layer between the 8 outer strands and the rope core for cranes and industrial applications including mobile, crawler and tower cranes.

Diameter | Approx. | Tensile strength (MPa) | ||||||||||||

1570 | 1670 | 1770 | 1870 | 1960 | 2160 | |||||||||

Minimum breaking load (kN) | ||||||||||||||

FC | WC | FC | WC | FC | WC | FC | WC | FC | WC | FC | WC | FC | WC | |

10 | 40.5 | 48.5 | 51.8 | 65.2 | 55.1 | 69.3 | 58.4 | 73.5 | 62 | 78 | 64.7 | 81.3 | 71.2 | 89.6 |

12 | 58.3 | 69.8 | 74.6 | 93.8 | 79.4 | 99.8 | 84.1 | 106 | 89 | 112 | 93.1 | 117 | 103 | 129 |

14 | 79.4 | 95.1 | 102 | 128 | 108 | 136 | 114 | 144 | 121 | 152 | 127 | 159 | 140 | 176 |

16 | 104 | 124 | 133 | 167 | 141 | 177 | 150 | 188 | 158 | 199 | 166 | 208 | 183 | 230 |

18 | 131 | 157 | 168 | 211 | 179 | 225 | 189 | 238 | 200 | 251 | 210 | 264 | 231 | 290 |

20 | 162 | 194 | 207 | 261 | 220 | 277 | 234 | 294 | 247 | 310 | 259 | 325 | 285 | 359 |

22 | 196 | 235 | 251 | 315 | 267 | 335 | 283 | 356 | 299 | 376 | 313 | 394 | 345 | 434 |

24 | 233 | 279 | 298 | 375 | 317 | 399 | 336 | 423 | 355 | 447 | 373 | 469 | 411 | 516 |

26 | 274 | 328 | 350 | 440 | 373 | 469 | 395 | 497 | 417 | 525 | 437 | 550 | 482 | 606 |

28 | 318 | 380 | 406 | 511 | 432 | 543 | 458 | 576 | 484 | 608 | 507 | 638 | 559 | 703 |

30 | 364 | 437 | 466 | 586 | 496 | 624 | 526 | 661 | 555 | 698 | 582 | 732 | 642 | 807 |

32 | 415 | 497 | 531 | 667 | 564 | 710 | 598 | 752 | 632 | 795 | 662 | 833 | 730 | 918 |

34 | 468 | 561 | 599 | 753 | 637 | 801 | 675 | 849 | 713 | 897 | 748 | 940 | 824 | 1040 |

36 | 525 | 629 | 671 | 844 | 714 | 898 | 757 | 952 | 800 | 1010 | 838 | 1050 | 924 | 1160 |

38 | 585 | 700 | 748 | 941 | 796 | 1000 | 843 | 1060 | 891 | 1120 | 934 | 1170 | 1030 | 1290 |

6XK36WS-EPIWRC

- Abrasion resistance performance.

- High breaking force.

- Outstanding bending fatigue performance

- Improved support of outer strands in service

6XK36WS-EPIWRC is a high performance compacted single layer constructed rope which incorporates an engineered extruded plastic profle between the 6 outer strands and the rope core for various cranes and industrial applications.

Rope Construction :6×K19S, 6×K26WS, 6×K31WS, 6×K36WS, 6×K41WS

In accordance with the EN 12385-4 standard.

Different constructions depending on the diameter.

Grade:1770mpa,1960mpa,2160mpa

Lay: sZ,zS,zZ,sS

Application: They can be used as Variable amplitude rope on mobile crane, vessel crane and grab bucket crane. And can be used as hoisting rope on container crane, floating crane, portal crane and steel factory crane etc… Also be applicable to multi-multiplying power system with smaller hoisting height, double coiling block system with matched left-hand and right-hand pairs using for deep hoisting height.

| Diameter (mm) | Approx. weight (kg/100m) | Tensile strength (MPa) | ||||||||||||

| 1570 | 1670 | 1770 | 1870 | 1960 | 2160 | |||||||||

| Minimum breaking load (kN) | ||||||||||||||

| FC | WC | FC | WC | FC | WC | FC | WC | FC | WC | FC | WC | FC | WC | |

| 12 | 61.2 | 67.0 | 84.3 | 93.8 | 89.7 | 99.8 | 95.1 | 106 | 100 | 112 | 105 | 117 | 116 | 129 |

| 14 | 83.3 | 91 | 115 | 128 | 122 | 136 | 129 | 144 | 137 | 152 | 143 | 159 | 158 | 176 |

| 16 | 109 | 119 | 150 | 167 | 159 | 177 | 169 | 188 | 179 | 199 | 187 | 208 | 206 | 230 |

| 18 | 138 | 151 | 190 | 211 | 202 | 225 | 214 | 238 | 226 | 251 | 237 | 264 | 261 | 290 |

| 20 | 170 | 186 | 234 | 261 | 249 | 277 | 264 | 294 | 279 | 310 | 292 | 325 | 322 | 359 |

| 22 | 206 | 225 | 283 | 315 | 301 | 335 | 320 | 356 | 338 | 376 | 354 | 394 | 390 | 434 |

| 24 | 245 | 268 | 337 | 375 | 359 | 399 | 380 | 423 | 402 | 447 | 421 | 469 | 464 | 516 |

| 26 | 287 | 314 | 396 | 440 | 421 | 469 | 446 | 497 | 472 | 525 | 494 | 550 | 545 | 606 |

| 28 | 333 | 365 | 459 | 511 | 488 | 543 | 518 | 576 | 547 | 608 | 573 | 638 | 632 | 703 |

| 30 | 382 | 419 | 527 | 586 | 561 | 624 | 594 | 661 | 628 | 698 | 658 | 732 | 725 | 807 |

| 32 | 435 | 476 | 600 | 667 | 638 | 710 | 676 | 752 | 714 | 795 | 749 | 833 | 825 | 918 |

| 34 | 491 | 538 | 677 | 753 | 720 | 801 | 763 | 849 | 806 | 897 | 845 | 940 | 931 | 1040 |

| 36 | 551 | 603 | 759 | 844 | 807 | 898 | 856 | 952 | 904 | 1010 | 947 | 1050 | 1040 | 1160 |

| 38 | 614 | 671 | 846 | 941 | 899 | 1000 | 950 | 1060 | 1010 | 1120 | 1060 | 1170 | 1160 | 1290 |

| 40 | 680 | 744 | 937 | 1040 | 1000 | 1110 | 1060 | 1180 | 1120 | 1240 | 1170 | 1300 | 1290 | 1430 |

| 42 | 750 | 820 | 1030 | 1150 | 1100 | 1220 | 1160 | 1300 | 1230 | 1370 | 1290 | 1430 | 1420 | 1580 |

| 44 | 823 | 900 | 1130 | 1260 | 1210 | 1340 | 1280 | 1420 | 1350 | 1500 | 1420 | 1570 | 1560 | 1740 |

| 46 | 899 | 984 | 1240 | 1380 | 1320 | 1470 | 1400 | 1550 | 1480 | 1640 | 1550 | 1720 | 1700 | 1900 |

| 48 | 979 | 1070 | 1350 | 1500 | 1440 | 1600 | 1520 | 1690 | 1610 | 1790 | 1680 | 1870 | 1860 | 2070 |

| 50 | 1060 | 1160 | 1460 | 1630 | 1560 | 1730 | 1650 | 1840 | 1740 | 1940 | 1830 | 2030 | 2010 | 2240 |

| 52 | 1150 | 1260 | 1580 | 1760 | 1680 | 1870 | 1790 | 1990 | 1890 | 2100 | 1980 | 2200 | 2180 | 2420 |

| 54 | 1240 | 1360 | 1710 | 1900 | 1820 | 2020 | 1930 | 2140 | 2030 | 2260 | 2130 | 2370 | 2350 | 2610 |

| 56 | 1330 | 1460 | 1840 | 2040 | 1950 | 2170 | 2070 | 2300 | 2190 | 2430 | 2290 | 2550 | 2530 | 2810 |

| 58 | 1430 | 1560 | 1970 | 2190 | 2100 | 2330 | 2220 | 2470 | 2350 | 2610 | 2460 | 2740 | 2710 | 3020 |

| 60 | 1530 | 1670 | 2110 | 2350 | 2240 | 2490 | 2380 | 2640 | 2510 | 2790 | 2630 | 2930 | 2900 | 3230 |

Your Ultimate Guide to Acquiring Plastic Impregnated Wire Rope

When it comes to acquiring plastic impregnated wire rope (PIWR), it’s essential to make informed decisions to ensure you receive a product that meets your specific needs. Here’s a comprehensive guide to help you through the process:

Table of contents

Chapt 1

What is Plastic impregnated Wire Rope

Plastic impregnated wire rope is a type of wire rope where the individual strands of wire are coated or impregnated with a plastic material. This coating serves several purposes:

Protection: The plastic coating provides protection against corrosion, abrasion, and other forms of wear and tear. This can significantly extend the lifespan of the wire rope, especially in harsh environments.

Enhanced Flexibility: The plastic coating can improve the flexibility of the wire rope, making it easier to handle and manipulate, particularly in applications where flexibility is important.

Improved Handling: The plastic coating can provide a more comfortable grip and reduce the risk of injury from sharp edges or protruding wires.

Reduced Friction: In some cases, the plastic coating can reduce friction between the individual strands of wire, which can improve the performance and longevity of the wire rope.

Plastic impregnated wire rope finds applications in various industries, including construction, mining, maritime, and agriculture, where durability, flexibility, and resistance to corrosion are important considerations.

Chapt 2

Advantage Of Plastic Impregnated Wire Rope

Plastic impregnated wire ropes offer several advantages due to their protective plastic coating. Here are some of the key benefits:

Corrosion Resistance: The plastic coating provides a barrier that prevents moisture and chemicals from reaching the wire rope, making it more resistant to rust and corrosion, which is essential in marine or outdoor applications.

Abrasion Resistance: The coating reduces the wear and tear that occurs when the wire rope comes into contact with rough surfaces, extending its service life in applications where abrasion is a concern.

Flexibility and Handling: The coating enhances the rope’s flexibility, making it easier to handle and reducing the chance of injury from wire splinters or protruding strands.

Noise Reduction: The plastic coating can absorb some of the noise and vibration that occur during operation, making the equipment quieter.

Friction Reduction: It reduces the friction between the rope’s strands, resulting in smoother movement, less internal wear, and longer rope life.

Electrical Insulation: The plastic coating provides a degree of electrical insulation, which can be beneficial in specific industrial environments.

Customization: Plastic coatings can be manufactured in different colors and materials, allowing customization to meet specific operational or safety requirements.

These advantages make plastic impregnated wire rope ideal for applications that require enhanced durability, safety, and performance.

Chapt 3

Plastic impregnated Wire Rope Regular Maintenance

Maintaining plastic impregnated wire rope is crucial for ensuring its longevity, reliability, and safety. Here’s a guide to regular maintenance:

1. Inspection:

- Visual Inspection: Regularly inspect the entire length of the wire rope for any signs of wear, corrosion, fraying, or damage.

- Check Connections: Examine connections, such as eye splices or fittings, for any signs of looseness or deformation.

- Look for Debris: Remove any dirt, debris, or foreign particles that may have accumulated on the wire rope.

2. Cleaning:

- Use Appropriate Cleaners: Clean the wire rope using a mild detergent or a specialized wire rope cleaner recommended by the manufacturer.

- Brushing: Use a soft brush to scrub the wire rope gently and remove any dirt or contaminants.

- Rinse Thoroughly: Rinse the wire rope with clean water to remove any leftover cleaning solution or residue.

- Dry Completely: Ensure the wire rope is completely dry before storage or further use to prevent corrosion.

3. Lubrication:

- Select Suitable Lubricant: Choose a lubricant specifically designed for plastic impregnated wire rope to maintain its flexibility and protect against corrosion.

- Apply Lubricant: Apply the lubricant evenly along the entire length of the wire rope, ensuring it penetrates between the strands.

- Use Proper Amount: Avoid over-lubricating, as excess lubricant can attract dirt and debris, leading to accelerated wear.

- Reapply as Needed: Monitor the condition of the wire rope and reapply lubricant periodically, especially after exposure to harsh conditions or heavy use.

4. Tension and Alignment:

- Check Tension: Ensure the wire rope is properly tensioned to prevent excessive sagging or slack, which can lead to increased wear and reduced performance.

- Alignment: Verify that the wire rope runs smoothly through pulleys, sheaves, or other guiding mechanisms without excessive friction or misalignment.

5. Corrosion Prevention:

- Inspect for Corrosion: Look for any signs of corrosion, especially in areas exposed to moisture, chemicals, or harsh environments.

- Address Rust: Remove surface rust using a wire brush or rust remover, and consider applying a corrosion-resistant coating or paint to affected areas.

- Protective Measures: Consider using protective sleeves or wraps in areas prone to corrosion to provide an additional layer of defense against environmental elements.

6. Record Keeping:

- Maintenance Logs: Keep detailed records of maintenance activities, including inspection dates, cleaning and lubrication schedules, and any repairs or replacements.

- Track Performance: Monitor the performance of the wire rope over time and identify any trends or patterns that may indicate the need for adjustments or replacements.

7. Training and Awareness:

- Employee Training: Provide training to personnel involved in handling and maintaining wire rope to ensure they understand proper maintenance procedures and safety precautions.

- Safety Awareness: Emphasize the importance of regular maintenance and safety practices to prevent accidents and ensure the reliability of equipment.

By following these maintenance guidelines, you can prolong the lifespan of plastic impregnated wire rope, minimize downtime, and ensure safe and efficient operation in various applications.

Chapt 4

Application of Plastic Impregnated Wire Rope

Plastic impregnated wire rope is highly valued for its enhanced durability, resistance to environmental elements, and added strength, making it suitable for a variety of demanding applications. Here are some key areas where this type of wire rope is commonly used:

Construction and Engineering

- Cranes and Hoists: Employed in cranes and hoists for lifting heavy materials at construction sites, offering high strength and reduced weight.

- Suspension Bridges: Acts as support cables in suspension bridges, providing essential strength and resistance to weather conditions.

- Architectural Structures: Integrated into architectural designs for aesthetic and functional purposes, such as tensioned structures and facades.

Towing and Mooring

- Maritime Industry: Used for towing vessels, barges, and other marine structures, as well as for mooring ships to docks or buoys.

- Offshore Operations: Essential for anchoring offshore structures, such as oil rigs and floating platforms, in challenging marine environments.

Utilities and Infrastructure

Telecommunication Lines: Supports and secures telecommunication cables, especially in remote or exposed areas.

Power Transmission: Used in power lines and electrical grids to provide a stable and secure infrastructure.

Mining and Oil Industries

- Extraction Equipment: Used in the cables of mining hoists and drilling rigs, where robust and durable cables are necessary to handle extreme loads and abrasive conditions.

Plastic impregnated wire rope’s enhanced properties make it suitable for these diverse applications where traditional wire rope might fail due to environmental challenges or heavy loads. Its use across these sectors highlights its adaptability and critical role in safety and functionality.

Chapt 5

How Do You Properly Select And Use Plastic Impregnated Wire Rope ?

Selecting and using plastic impregnated wire rope (PIWR) involves understanding its unique characteristics and applications. PIWR is wire rope that has been infused with a plastic material, typically either through the core (core impregnated) or by encapsulating the entire rope (fully impregnated). This type of rope offers enhanced properties such as increased wear resistance, improved corrosion resistance, and reduced internal friction. Here are key steps and considerations for properly selecting and using plastic impregnated wire rope:

1. Understand the Application Requirements

Load Capacity: Determine the weight and nature of the loads the rope will need to handle.

Environment: Consider the operating environment, including exposure to chemicals, moisture, and temperature variations.

Abrasion and Wear: Evaluate the potential for abrasion and other forms of wear which the rope might be exposed to.

Bending and Flexibility: Consider how frequently the rope will be bent or flexed during operation.

2. Choose the Right Type of Plastic Impregnation

Core Impregnated: Plastic material is infused within the core, offering added internal lubrication and protection against internal abrasion. Suitable for environments where internal rope integrity is critical.

Fully Impregnated: The entire rope, including both core and outer strands, is coated with plastic. This type offers maximum protection against abrasion, corrosion, and UV light, making it ideal for harsh environments.

3. Select the Appropriate Rope Configuration

Strand and Wire Construction: Depending on the flexibility and strength required, choose the appropriate strand layout and wire configuration.

Diameter and Length: Based on the load requirements and mechanical equipment used, select the diameter and length of the rope.

4. Installation and Handling

Proper Installation: Ensure that the wire rope is correctly installed in the machinery, with attention to alignment and tensioning.

Avoid Sharp Bends: Sharp bends can damage the rope, especially at the plastic layer. Ensure that the rope operates within the minimum bend radius recommended by the manufacturer.

Regular Maintenance: Check for signs of wear, cracking in the plastic, or any deformations. Regularly clean and inspect the rope to ensure it remains in good condition.

5. Compliance with Standards

Ensure that the wire rope complies with relevant industry standards, such as EN12385-4 etc.

6. Training and Safety

Train operators on the proper use and handling of plastic impregnated wire rope to prevent misuse and premature failure.

Implement regular safety checks and maintenance routines to ensure ongoing reliability and safety.

By following these guidelines, you can effectively select and use plastic impregnated wire rope in a way that maximizes its benefits while ensuring safety and durability in its application.

Get the catalogue

Leave a request and we will send you the catalogue with Aulone steel wire ropes by e-mail

86-15573139663

86-15363044363