Answer: The “35×7” wire rope is a type of rotation-resistant rope known for its strength and low rotation characteristics. It consists of 35 strands, each with 7 wires.

Answer: The “19×7” in wire rope indicates it has 19 strands, each containing 7 wires, designed to minimize rotation under load.

This article will continue the discussion on 19×7 wire rope from the following aspects.

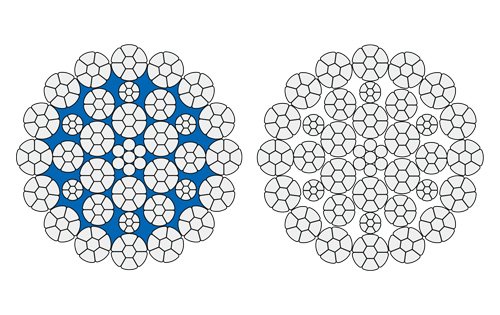

Rotation resistant and non-rotation wire ropes: 35(W)x7

The “35(W)x7” wire rope configuration is a specific type of rotation-resistant wire rope. Here’s a detailed look at its structure and characteristics:

Structure of 35(W)x7 Wire Rope

-

35(W)x7: This notation suggests the rope has 35 outer strands wound around a core, with each outer strand containing 7 wires. The “W” in the designation usually stands for a Warrington construction, which involves a specific pattern of large and small wires alternately laid to form the strand. This arrangement helps in optimizing the wire rope’s flexibility and contact area, enhancing its load-bearing capacity.

Characteristics

-

Rotation Resistance: The 35(W)x7 wire rope is designed to be rotation-resistant, meaning it reduces the amount of torque and rotation transferred to the load during lifting operations. This is achieved through its specific construction that balances forces within the rope to prevent twisting.

-

Strength and Stability: The combination of multiple strands and the Warrington construction provides a high level of strength and stability, making it suitable for heavy-duty lifting tasks.

-

Flexibility: Despite its robust structure, the rope maintains a degree of flexibility, which is crucial for applications involving the movement over sheaves and pulleys.

Applications

-

Crane Lifting: Particularly useful in crane operations where precision in load handling and the prevention of load rotation are critical.

-

Hoisting Systems: Used in various hoisting systems in industrial, construction, and maritime settings.

Maintenance and Considerations

-

Regular Inspection: It is crucial to regularly inspect the rope for signs of wear, corrosion, or damage to maintain its integrity and performance.

-

Proper Handling: Correct installation and handling are vital to avoid premature wear and potential safety issues, such as kinking or birdcaging.

The “35(W)x7” wire rope is a reliable choice for applications requiring high strength, minimal rotation, and operational safety, particularly in environments demanding precise load control and stability.

Galvanised steel wire rope 35Wx7 / compacted

The “35Wx7” galvanized steel wire rope, when compacted, is a highly specialized type of wire rope designed for demanding lifting and hoisting applications where both strength and precise load handling are essential. Here’s a detailed overview:

Structure of 35Wx7 Compacted Wire Rope

- 35Wx7: This notation indicates that the rope consists of 35 outer strands, each containing 7 wires. The “W” stands for Warrington construction, a layout featuring alternating large and small wires to optimize flexibility and contact area.

- Compacted: Compacting the wire rope involves flattening or compressing the strands, which increases the contact area with sheaves and drums, reduces internal abrasion, and enhances the rope’s overall strength and fatigue resistance.

Product Types Available

- Bright or galvanized

- Regular lay or Lang′s lay (Lang′s lay is standard)

- Option: Plastic coated steel core

Characteristics

- Galvanized Coating: The galvanization process involves coating the steel wires with a protective layer of zinc, which provides excellent corrosion resistance, making the rope suitable for outdoor or marine environments.

- Rotation Resistance: This rope is designed to be rotation-resistant, minimizing the torque and rotation that can be transferred to the load during lifting operations. This makes it ideal for uses where preventing the load from twisting is crucial.

- Increased Load Capacity: Compaction increases the rope’s density and allows it to bear greater loads compared to non-compacted ropes of the same diameter.

Applications

- Heavy Lifting and Cranes: Ideal for crane operations in construction, maritime, and industrial settings where heavy loads and high lifting capacities are common.

- Hoisting and Rigging: Used in hoisting applications in industrial environments and for rigging heavy equipment, where rotation resistance and high strength are necessary.

- Marine Applications: The galvanized finish offers corrosion resistance, making it suitable for marine applications, including shipping and offshore drilling.

Technical Parameters

|

Diameter |

Approx. weight (kg/100m) |

Tensile strength (MPa) |

||

|

(mm) |

1770 |

1960 |

2160 |

|

|

Minimum breaking load (kN) |

||||

|

8 |

33 |

51 |

56 |

62 |

|

9 |

41 |

65 |

71 |

79 |

|

10 |

51 |

80 |

88 |

97 |

|

11 |

62 |

96 |

107 |

118 |

|

12 |

73 |

115 |

127 |

140 |

|

13 |

86 |

135 |

149 |

164 |

|

14 |

100 |

156 |

173 |

191 |

|

15 |

115 |

179 |

198 |

219 |

|

16 |

131 |

204 |

226 |

249 |

|

17 |

147 |

230 |

255 |

281 |

|

18 |

165 |

258 |

286 |

315 |

|

19 |

184 |

288 |

318 |

351 |

|

20 |

204 |

319 |

353 |

389 |

|

21 |

225 |

351 |

389 |

429 |

|

22 |

247 |

386 |

427 |

470 |

|

23 |

270 |

421 |

467 |

514 |

|

24 |

294 |

459 |

508 |

560 |

|

25 |

319 |

498 |

551 |

608 |

|

26 |

345 |

538 |

596 |

657 |

|

27 |

372 |

581 |

643 |

709 |

|

28 |

400 |

624 |

691 |

762 |

|

29 |

429 |

670 |

742 |

817 |

|

30 |

459 |

717 |

794 |

875 |

|

31 |

490 |

765 |

848 |

934 |

|

32 |

522 |

816 |

903 |

995 |

|

35 |

625 |

976 |

1080 |

1191 |

|

36 |

661 |

1032 |

1143 |

1260 |

|

39 |

776 |

1211 |

1342 |

1478 |

|

40 |

816 |

1274 |

1411 |

1555 |

Maintenance and Considerations

- Regular Inspection: It is crucial to regularly inspect the rope for signs of wear, such as broken wires, rust, and deformation. Galvanization delays rust, but damaged coatings can expose steel to corrosion.

- Proper Handling: To maintain the integrity and performance of the rope, proper handling, installation, and maintenance are vital. This includes avoiding sharp bends and following the manufacturer’s guidelines on rope care and usage.

Overall, the “35Wx7” compacted galvanized steel wire rope offers a robust solution for applications demanding high strength, minimal rotation, and resistance to environmental challenges. Its design and characteristics make it a preferred choice in many heavy-duty lifting scenarios.

35(W) x K7, 40(W) x K7 Compacted Wire Rope

The 35(W) x K7 and 40(W) x K7 compacted wire ropes are specialized configurations particularly suited for applications that require high load capacities and minimal stretch under load, such as in crane operations, mining, and heavy-lift projects. Here’s a breakdown of their characteristics and benefits:

1. Compacted Strand Design

- Reduced Internal Abrasion and Increased Fatigue Resistance: Compaction increases the contact area between individual wires and strands, reducing internal abrasion which can lead to wire failures. This also enhances fatigue resistance under dynamic loads.

- Smooth Outer Surface: The compaction process creates a smoother exterior which reduces the wear on sheaves and drum surfaces, prolongs the life of the rope, and minimizes friction.

2. Construction Details

- Core: The core of these ropes is typically a plastic or steel core (IWRC – Independent Wire Rope Core), which provides additional support to the strands, maintaining their position and structural integrity under load.

- Strand Layout: The (W) in the designation typically refers to Warrington, a specific arrangement of wires within the strands, enhancing flexibility and strength. The K7 indicates a specific type of lay and the number of wires in the outer strands.

3. Application-Specific Benefits

- 35(W) x K7: With a slightly smaller diameter, this rope configuration is more flexible, making it suitable for equipment where ease of handling and bending are important, yet still requiring high strength.

- 40(W) x K7: This thicker rope offers greater load capacity and is ideal for heavier lifting applications, where the additional diameter provides increased durability and load-bearing capacity.

4. Durability and Performance

- High Load Capacity: Both configurations support high axial loads without significant stretching, a critical feature for precise lifting operations.

- Resistance to Crushing and Deformation: Compacted wire ropes are more resistant to flattening under load, maintaining their round shape better under pressure.

5. Application

- Cranes and Hoisting: Used in tower cranes, mobile cranes, bridge cranes, and other lifting devices.

- Mining and Excavation Equipment: Ideal for hoisting and dragline operations.

- Marine Applications: Suitable for offshore mooring, where high strength and resistance to environmental elements are required.

When selecting a wire rope like 35(W) x K7 or 40(W) x K7, it’s essential to consider the specific requirements of your application, including load, environmental conditions, and mechanical compatibility with your equipment. Regular inspections and proper maintenance are critical to ensure safety and extend the lifespan of the rope.

Differences Between Compacted 35XK7 and 35x7 Wire Rope

Compacted 35XK7 and standard 35×7 wire ropes are designed for high-performance applications where strength, flexibility, and durability are crucial. Although they share similar numeric designations, the key differences between these two types of wire ropes lie in their construction techniques and performance characteristics. Here’s a detailed comparison:

1. Construction and Design

- 35XK7 Compacted: This wire rope has undergone a compaction process, which involves flattening the strands before they are twisted into the rope. This process increases the contact area between wires and strands, leading to several performance benefits.

- 35×7 Standard: In a standard 35×7 wire rope, the strands are not compacted. It consists of 35 wires arranged in 7 strands.

2. Diameter and Cross-Sectional Area

- Compacted: The compaction process increases the cross-sectional area that effectively contacts loads, allowing the rope to bear greater weights. It also makes the rope denser and generally stiffer.

- Standard: The standard 35×7 has a more open structure compared to the compacted version, which can result in less resistance to abrasion and slightly reduced load capacity due to smaller contact areas.

3. Flexibility

- Compacted 35XK7: Despite its increased strength and load capacity, the compaction process can decrease the rope’s overall flexibility. This can be a drawback in applications requiring high flexibility.

- 35×7 Standard: This rope retains more flexibility, which makes it suitable for applications involving complex reeving systems or where the rope needs to pass through numerous pulleys and sheaves.

4. Fatigue Resistance

- Compacted: Improved fatigue resistance due to the greater contact area and reduced internal movement of wires and strands. This leads to a longer lifespan under cyclical loads.

- Standard: The standard rope may experience quicker wear and fatigue under similar conditions because of more internal movement and less contact area.

5. Surface Contact and Wear

- Compacted 35XK7: The smoother outer surface reduces wear on sheaves and drum surfaces, which is beneficial in prolonging the equipment’s life.

- 35×7 Standard: With a more traditional structure, the standard rope might not distribute load as evenly across its surface, potentially increasing wear and tear on contact points.

6. Application Suitability

- Compacted: Best suited for heavy-duty lifting, where high load capacity, reduced stretch, and extended rope life are essential.

- Standard 35×7: Ideal for applications requiring more flexibility and where load conditions are less severe.

Summary

Choosing between a compacted 35XK7 and a standard 35×7 wire rope depends largely on specific application needs, including the required load capacity, operational conditions, and necessary flexibility. Compacted ropes are generally preferable in harsher, high-load environments, while standard ropes may be more appropriate where higher flexibility and ease of handling are required. Regular maintenance and inspections are crucial for both types to ensure optimal performance and safety.

35WXK7 scrapping standards and maintenance

The 35WXK7 wire rope is a specialized type of wire rope used in various heavy-load applications, notably in cranes and lifting equipment. Proper maintenance and timely scrapping are crucial to ensure the safety and efficiency of operations involving this type of rope. Here are the guidelines for maintenance and scrapping standards for 35WXK7 wire rope:

Maintenance Guidelines

-

Regular Inspections: Perform visual and manual inspections regularly to identify signs of wear, corrosion, broken wires, distortion, or other defects. Frequency should increase with the severity of service conditions.

-

Lubrication: Proper lubrication is essential to protect the rope from corrosion and wear. The lubricant should be compatible with the rope material and suitable for the environmental conditions of the operation.

-

Cleaning: Keep the wire rope clean from debris and contaminants that can accelerate wear or cause corrosion. Use appropriate cleaning agents that do not degrade the rope or its lubrication.

-

Proper Handling and Storage: Avoid practices that can kink, crush, or otherwise damage the rope. Ensure that the rope is stored in a way that prevents environmental damage and is coiled or spooled properly to avoid distortions.

-

Load Monitoring: Never exceed the recommended load capacity. Overloading can cause stretching, distortion, and internal damages that might not be immediately apparent.

-

Record Keeping: Maintain records of installation, maintenance, inspections, and incidents to track the rope’s performance and predict its lifespan accurately.

Scrapping Standards

-

Visible Broken Wires: Scrap the rope if there are more than six broken wires in one lay length or three broken wires in one strand in one lay length.

-

Diameter Reduction: Retire the rope if it shows more than 10% reduction in diameter from its original diameter, indicating significant wear and loss of metallic area.

-

Corrosion: Evidence of severe corrosion that could compromise the strength or integrity of the rope.

-

Distortion: Any kinking, crushing, birdcaging, or other damage that distorts the rope structure.

-

Fatigue: Indications of fatigue such as wires or strands that appear popped out or gaps in the lay structure.

-

Load Issues: Any incident of shock loading or overloading should trigger a thorough inspection, and the rope should be scrapped if any damage is evident.

-

External and Internal Wear: Check not only the external condition but also internal wear and tear, which might require more specialized inspection techniques like magnetic or radiographic testing.

Conclusion

Regular maintenance, coupled with adherence to scrapping standards, ensures the safety and longevity of 35WXK7 wire ropes in critical applications. Always follow the manufacturer’s guidelines and industry standards for the specific use case of your wire rope. Additionally, training for personnel involved in the handling and inspection of wire ropes can greatly enhance safety and operational efficiency.

Ask For A Quick Quote

Fill out a quick form to get a personalized quote tailored to your specific needs.