Are you struggling to find reliable wire rope suppliers? Do quality issues keep you awake at night? High-quality wire rope is essential for safety and performance.

When buying steel cable and wire rope, you must prioritize quality, tensile strength, breaking load, and certifications to ensure safety and durability for critical applications.

Let me tell you about a recent experience. A client, a major buyer of industrial materials, reached out to me. They were tired of inconsistent quality and late deliveries from their current suppliers. This is a common story I hear.

How Does Quality Affect Wire Rope Performance?

Finding the right wire rope is crucial. Poor quality can lead to serious problems. It affects how long the rope lasts and how safe it is to use.

Quality directly impacts wire rope performance by determining its strength, durability, and resistance to wear, ensuring safe and efficient operation in demanding industrial applications.

Here at Aulone, we understand these concerns deeply. Our factory has four production lines. We focus on making sure every rope meets high standards. We know that a small flaw can cause a big issue.

Why Quality Matters:

- Safety: A high-quality rope is less likely to break. This prevents accidents.

- Durability: Good quality means the rope lasts longer. You do not need to replace it often. This saves money.

- Performance: A strong rope does its job better. It can handle more weight. It works well under stress.

Let’s look at what high quality means for us. We ensure our ropes have high tensile strength. This is how much pull they can handle before stretching. We also check their breaking load. This is the maximum force they can take before snapping. These are not just numbers. They are promises of safety and reliability.

We also make sure our products meet international standards. For example, our ropes comply with EN12385-4. This standard is important for wire ropes for general lifting purposes. We can also provide certificates like BV & CE, RMRS, DNV, and ABS. These certificates show our commitment to quality. They give you peace of mind.

Quality Control Checklist:

| Feature | Description | Importance |

|---|---|---|

| Material Purity | Using high-grade steel. | High |

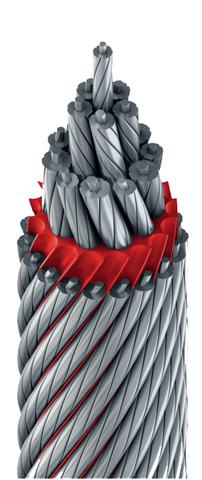

| Strand Formation | Consistent twisting and lay of strands. | High |

| Surface Finish | Smooth, no defects or sharp edges. | Medium |

| Lubrication | Proper application for reduced friction. | Medium |

| Dimensional Accuracy | Precise diameter and length. | High |

We also offer options like plastic impregnated and galvanized ropes. Plastic impregnation helps protect the core. It extends rope life. Galvanized ropes resist rust. This is great for harsh environments. Our main customers are from places like Singapore, Indonesia, and Saudi Arabia. They need ropes that can handle tough conditions.

Why are Certifications Important for Wire Rope?

Certifications are not just papers. They prove that a product meets certain rules. They show that a supplier follows strict quality control methods.

Certifications are important for wire rope because they verify compliance with industry standards, ensuring the product’s safety, reliability, and performance for specific applications and regulatory requirements.

When a product is certified, it means an independent group has checked it. They confirm it meets specific criteria. This is good for buyers. It means they can trust the product.

The Role of Certifications:

- Proof of Compliance: Certificates show the rope meets national or international standards. This is important for legal reasons.

- Safety Assurance: Certified ropes are less likely to fail. This protects workers and equipment.

- Credibility: A certified supplier is usually more trustworthy. They invest in quality control.

For example, we frequently provide BV & CE, RMRS, DNV, and ABS certificates. These are globally recognized. BV & CE is common for many industries. RMRS is important for maritime use in Russia. DNV and ABS are key for marine and offshore applications. Our ropes are used in countries like Australia and Canada. These countries have very high standards. We ensure our products meet them.

Key Certifications and Their Meanings:

| Certification | Industry Focus | What it Means |

|---|---|---|

| EN12385-4 | General Lifting | Compliance with European standards for wire rope. |

| BV & CE | Various, European Export | Meets European safety, health, and environmental rules. |

| RMRS | Russia, Marine | Approved for ships and marine structures by Russian Register. |

| DNV | Marine, Offshore | Meets safety and quality rules for shipping by DNV GL. |

| ABS | Marine, Offshore | Approved for marine vessels and offshore units by ABS. |

These certificates are important for purchasing managers. They need to ensure their company uses safe and compliant materials. For instance, if you are buying for a mining company, specific certifications might be required. We work with clients to provide the right documents. This makes the buying process smoother. We send our products to places like UAE and Russia. Each region has its own rules. We help our clients navigate these rules effectively.

What Customization Options Are Available for Wire Rope?

Every project is different. Sometimes, you need a wire rope that is not standard. This is where customization comes in.

Customization options for wire rope include specific diameter, lengths, constructions (e.g., 6×19, 6×36), materials (e.g., galvanized, stainless steel),tensile strength, min breaking force, end condition and even incorporating custom logos to meet unique project requirements.

You might need a special size or a unique material. Or perhaps, you want your company’s logo on the product. These are all possible.

Why Customization is Important:

- Perfect Fit: A custom rope fits your exact needs. It performs better.

- Brand Identity: Adding your logo helps promote your brand.

- Specific Applications: Some jobs need special features. Customization provides this.

At Aulone, we offer various customization services. We have many types of rope. This includes crane wire rope, elevator wire rope, and mining wire rope. We also make galvanized wire rope and marine wire rope. We even produce synthetic rope and stainless steel wire rope. Each type can be adjusted.

For example, a client recently asked for a specific length of elevator wire rope. They also needed it to be plastic impregnated for extra durability. We were able to meet their exact specifications. Another time, a distributor wanted their logo on a batch of galvanized wire ropes. We printed their logo clearly on each spool.

Customization Examples:

| Type of Customization | Description | Benefit |

|---|---|---|

| Length | Cutting ropes to precise, required lengths. | Eliminates waste, ensures exact fit. |

| Construction | Varying the number of strands and wires. | Optimizes flexibility, strength for use. |

| Materials | Choosing galvanized, stainless steel, etc. | Enhances resistance to corrosion or wear. |

| Coatings/Treatments | Applying plastic impregnation or lubrication. | Increases durability, extends lifespan. |

| Logo/Marking | Adding company logos or specific markings. | Brand recognition, product identification. |

We also offer specialized assemblies and wire products. We even make piling tools. This wide range means we can meet many unique demands. Our team understands that purchasing managers often face complex requirements. We work hard to provide flexible solutions. This flexibility sets us apart. We serve clients in countries like Vietnam and Russia. Each country might have unique standards or preferences. We adjust our products to fit these diverse market needs.

What are the Different Types of Wire Rope and Their Uses?

Choosing the right type of wire rope is essential. Each type is designed for specific jobs. Using the wrong one can lead to failure.

Different types of wire rope, such as crane, elevator, mining, and marine wire ropes, are designed with specific constructions and materials to suit unique applications based on required strength, flexibility, and environmental resistance.

Understanding these differences helps you make the best choice. It ensures safety and performance.

Overview of Wire Rope Types:

- Crane Wire Rope: Built for heavy lifting. It has high breaking load.

- Elevator Wire Rope: Designed for smooth, reliable, and safe vertical movement.

- Mining Wire Rope: Made for tough underground conditions. It resists wear and tear.

- Marine Wire Rope: Treated to resist rust and saltwater. It is used on ships and docks.

- Galvanized Wire Rope: Coated with zinc. It prevents rust. Good for outdoor use.

- Stainless Steel Wire Rope: Resists corrosion. Good for food or pure environments.

- Synthetic Rope: Lighter than steel. It floats. Good for certain marine uses.

We produce a wide selection of these ropes. Our focus is always on quality. For example, our crane wire ropes are made to handle extreme loads. They are used in large construction projects. Our elevator ropes ensure high safety standards for buildings. Mining companies rely on our ropes for deep underground operations.

Common Wire Rope Types and Uses:

| Wire Rope Type | Primary Use | Key Feature |

|---|---|---|

| Crane Wire Rope | Lifting heavy loads, construction rigging | High breaking strength. |

| Elevator Wire Rope | Elevators, vertical transportation | Smooth operation, durability. |

| Mining Wire Rope | Excavation, material handling in mines | Abrasion and fatigue resistance. |

| Marine Wire Rope | Ships, offshore platforms, fishing | Corrosion resistance, flexibility. |

| Galvanized Wire Rope | Outdoor, general industrial use | Rust protection, cost-effective. |

| Stainless Steel Wire Rope | Food industry, sterile environments | Excellent corrosion resistance. |

| Synthetic Rope | Mooring, towing, rescue operations | Lightweight, floating, strong. |

Our product range also includes specialized assemblies. These are custom-made solutions for unique needs. For example, some buyers might need specific end fittings. We can provide these. We export to many countries, including Singapore, Indonesia, and Saudi Arabia. Each country has different industry needs. We ensure our product range covers these diverse requirements effectively. Our commitment is to provide the right rope for the right job, every single time.

Conclusion

Choosing the right steel cable and wire rope is crucial. Focus on quality, certifications, customization, and type. This ensures safety and good performance for all your projects.