Are you tired of tangled ropes and unexpected failures? Many lifting operations face this challenge. You need a solution that brings safety and efficiency.

Non-rotating wire ropes are crucial because they prevent twisting under load, ensuring stable and safe lifting. This design reduces downtime and enhances operational reliability for many heavy-duty tasks.

Let me tell you about a time I saw firsthand the difference a quality rope makes. Imagine a massive crane, lifting a vital component. The success of that lift, and the safety of everyone involved, hinges on the right kind of rope.

What is a non-rotating wire rope, and how does it work?

A standard wire rope can twist when under heavy strain. This twisting causes problems. Non-rotating ropes are different.

A non-rotating wire rope is a special type of rope where the individual strands and layers are arranged to counteract torsional forces. This design prevents the rope from rotating or spinning when under load, ensuring stability.

Let me explain this in more detail. Traditional ropes twist because of their construction. When you pull a heavy load, the rope wants to unwind. This unwinding makes the load spin. This can be dangerous. It makes precise placement impossible. It adds stress to the crane and the load.

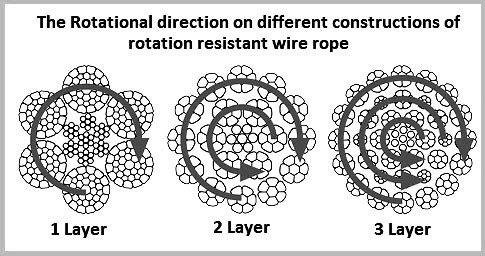

Non-rotating ropes fix this. They have a special design. Their inner strands are laid in one direction. Their outer strands are laid in the opposite direction. This counteracts the twisting. Imagine two forces pushing against each other, cancelling each other out. That is how a non-rotating rope works.

Consider these key aspects:

Understanding the construction of non-rotating wire ropes

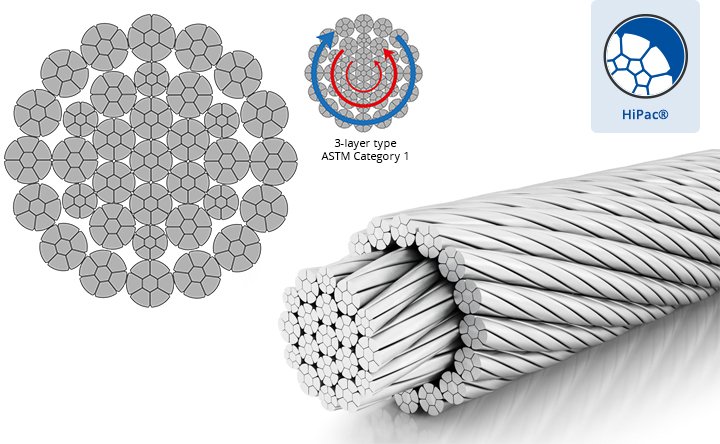

Non-rotating ropes are built with multiple layers of strands. Each layer has a specific lay direction.

| Layer Type | Strand Lay Direction | Purpose |

|---|---|---|

| Inner Strands | Right Hand Lay | Creates initial torsion |

| Outer Strands | Left Hand Lay | Counteracts inner torsion precisely |

| Core | Independent Wire Rope Core (IWRC) | Provides stable foundation for layers |

This unique construction means that as the rope stretches under load, the tendency of one layer to twist is perfectly balanced by the opposite tendency of another layer. This keeps the rope from rotating.

Benefits of non-rotating ropes in real-world applications

Using non-rotating ropes offers many benefits. I have seen them transform operations.

- Enhanced Safety: The biggest benefit is safety. A stable load is a safe load. It prevents uncontrolled spinning. This reduces risks to workers and equipment.

- Improved Efficiency: With no rotation, precise load placement becomes easy. This speeds up operations. It reduces wasted time. This means projects finish faster.

- Reduced Wear and Tear: Less twisting means fewer stresses on the rope itself. This extends the rope’s life. It saves money on replacements. It also reduces wear on crane components.

- Versatility: These ropes are suitable for many uses. This includes general lifting, heavy lifts, and sensitive material handling.

How do non-rotating wire ropes meet strict quality and safety standards?

Meeting standards is very important. Our ropes follow global rules for safety and quality. This gives you peace of mind.

Non-rotating wire ropes meet strict quality and safety standards by adhering to specifications like EN12385-4. This ensures their high tensile strength, breaking load, and overall reliable performance in demanding lifting applications.

When I talk to clients, quality always comes up. “How do I know this rope is safe?” they ask. My answer is always about the standards we follow. We do not just make ropes; we make sure they are certified. We test them rigorously. For example, our ropes comply with EN12385-4. This is a European standard for wire ropes. It covers safety. It covers how ropes perform. It ensures high tensile strength. It ensures a strong breaking load.

We can also provide other certificates. These include BV & CE, RMRS, DNV, and ABS. These are global certificates. They mean our ropes are good for various environments. This includes marine use or specialized industrial tasks.

The importance of certifications in wire rope selection

Certifications are not just papers. They are proof of quality. They mean a rope has been tested. They mean it meets specific safety levels.

| Certification | What it Means | Relevant Industry |

|---|---|---|

| CE | European Conformity | General Lifting |

| BV | Bureau Veritas and | Global, EU Market |

| RMRS | Russian Maritime Register of Shipping | Marine, Russia |

| DNV | Det Norske Veritas – Germanischer Lloyd | Marine, Oil & Gas |

| ABS | American Bureau of Shipping | Marine, Americas |

When you pick a rope, check its certifications. This tells you if it is right for your job. Using a certified rope means you are following safety rules. It keeps your workers safe. It protects your equipment. It also avoids legal issues.

Quality control steps for non-rotating wire ropes

We put great effort into quality control. Our factory has four production lines. This means we can handle many orders. But quantity never compromises quality.

Our process includes:

- Raw Material Inspection: We check all incoming materials. This includes steel wires. They must meet our strict standards.

- In-Process Monitoring: During production, we check every step. This includes wire drawing. It includes stranding. It includes closing the rope.

- Final Product Testing: Every batch of rope goes through tests. We check tensile strength. We check breaking load. We perform visual inspections.

- Traceability: Every rope we sell has a unique ID. We can trace it back to its materials and production batch. This ensures accountability.

This strict process results in a high-quality product. It is a product you can trust.

What challenges do wire rope buyers face, and how can Aulone address them?

Buyers often face common problems. I hear about them all the time. Pricing, quality control, and obtaining the right certifications are big concerns.

Wire rope buyers often struggle with competitive pricing, maintaining strict quality control, and securing necessary certifications. Aulone addresses these by offering high-quality, certified ropes at competitive prices, backed by robust production and excellent service.

I spoke with a potential client recently. He used to buy from German brands. He told me about his pain points: high costs, very strict quality checks, and needing specific certificates. These are common issues. Many buyers need reliable products that also fit their budget. They need ropes that meet tough standards.

Here is how we help:

Addressing pricing concerns without compromising quality

Many buyers, especially from countries like Russia, look for good value. They need competitive prices. But they also demand high quality. This is a balance we work hard to achieve.

We do this through:

- Efficient Production: Our four production lines allow us to produce efficiently. This lowers our costs.

- Direct Sourcing: We source our raw materials directly. This removes middlemen. It reduces material costs.

- Strong Supply Chain: We have a stable supply chain. This helps us manage costs and delivery times.

We offer quality that matches top brands. But we do it at a more competitive price.

Ensuring strict quality control and relevant certifications

Quality is not just a feature. It is a foundation for us. For buyers who previously worked with high-end suppliers, a transition can be tricky. They expect nothing but the best.

- Our Quality Focus: We have a dedicated team for quality control. They oversee every stage. From raw material to finished product, everything is checked.

- Global Standard Compliance: We comply with many international standards. This list includes EN12385-4. We can also provide certificates like BV & CE, RMRS, DNV, and ABS. This ensures our ropes are accepted globally.

- Customization Options: We understand that every client has specific needs. We offer customizable logos. This helps clients with branding. It also ensures the rope meets their exact project specifications.

Solving logistical and payment challenges for international buyers

International trade has its own issues. Payment terms and shipping can be complex. We make it easy.

We offer flexible payment terms. A common one is 30% T/T in advance. The balance is paid against a copy of the Bill of Lading (B/L). This offers security for both sides.

We export to many countries. This includes Singapore, Indonesia, Vietnam, Saudi Arabia, UAE, Russia, Australia, and Canada. This wide reach shows our experience in global logistics. We know how to get our products to you, wherever you are.

Conclusion

Non-rotating wire ropes are essential for safe and efficient lifting. At Aulone, we provide high-quality, certified ropes that address buyer needs for performance, price, and compliance. We deliver globally, ensuring your operations are safe and successful.