What Are Chain Slings and Why Are They Essential for Heavy Lifting?

Imagine your crane suddenly fails mid-operation. Chain slings prevent such accidents. I’ve seen more than 200 tons lifted safely using them, while weaker alternatives often failed under smaller loads.

What’s the Real Strength of Galvanized Wire Rope with Steel Core?

Are you struggling to find wire rope that can withstand extreme conditions? Many products promise durability, but fall short under pressure. We understand the frustration of equipment failure and project delays.

What are the Galvanized Wire Rope FAQs You Need to Know?

Are you struggling to choose the right galvanized wire rope for your project? Many people find it confusing to understand the specifications and uses of different wire ropes. This can lead to costly mistakes and inefficient operations.

What’s the Right Wire Rope for Piling Machines?

Choosing the right wire rope is crucial for any project. It’s not just about the rope’s specs; it’s about how it fits your equipment. Different machines and jobs need different solutions. We’ll explore how to pick wire ropes for various machines, starting with piling equipment.

How to Choose the Right Wire Rope for Your Crawler Crane?

Selecting the right wire rope is crucial. It’s not just about the rope’s specs; it’s about fitting the equipment perfectly. This is why tailored solutions for different industries and machines are so important. We’ll explore selection for various equipment to answer your questions.

How Does Aulone Wire Rope Empower the Steel Industry?

Are you struggling with unreliable wire ropes for your steel operations? It’s a common problem that causes costly downtime and safety concerns.

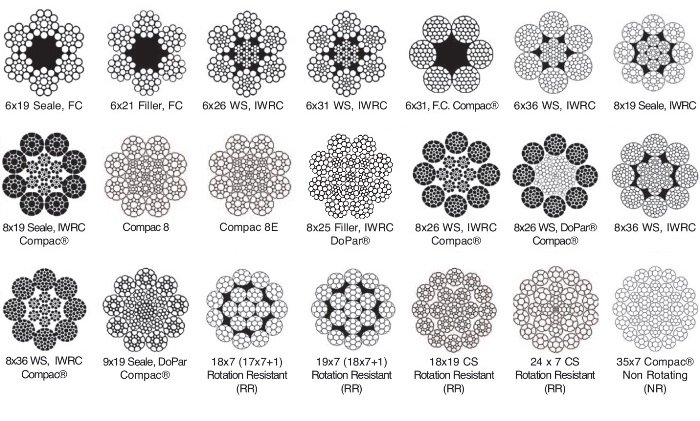

What Makes Class 6×19 IWRC and Fiber Core Wire Ropes the Preferred Choice?

Are you struggling to find reliable wire ropes that meet stringent quality standards? We understand the frustration of uncertain sourcing and the pressure to deliver.

How Do I Select the Right Wire Rope Clip?

Are you struggling to find the perfect wire rope clip? Many people face this challenge, often leading to costly mistakes and unsafe applications. It’s a common problem that affects the reliability of your lifting and rigging operations.

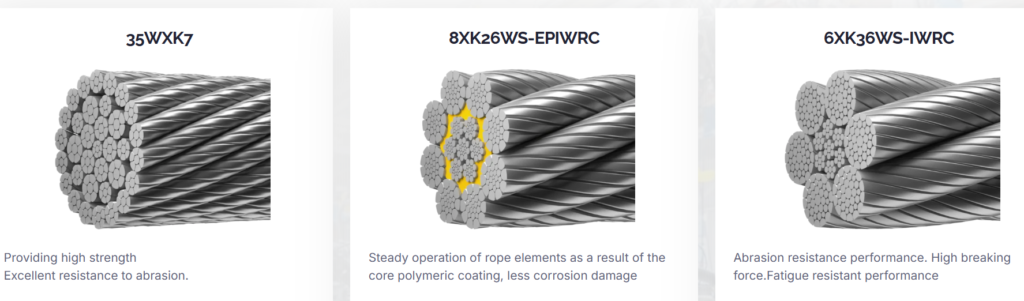

Is Breaking Load the Key Factor When Selecting Wire Rope?

Are you overwhelmed by too many wire rope models? Do you find yourself confused by the numbers on spec sheets? If you’re a purchasing manager or engineering lead, choosing the right wire rope can feel like navigating a minefield, especially when price seems to be the only deciding factor.

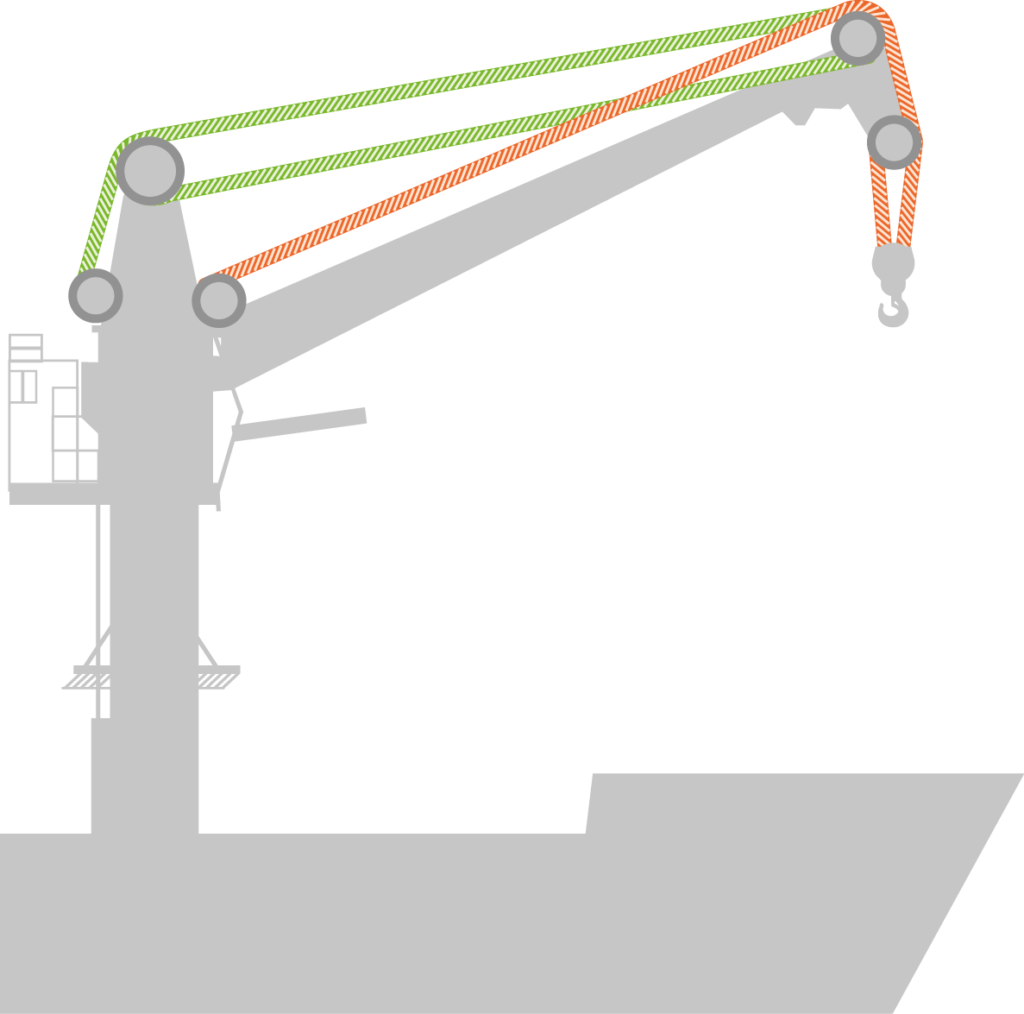

How Do I Select the Right Wire Rope for Marine Deck Cranes?

Selecting wire ropes isn’t just about their specs; it’s about how well they fit your equipment. Different industries and machines need different solutions. I’ll share practical insights to help you choose the best wire rope, starting with marine deck cranes, which face some of the toughest conditions.

Aulone supports the operation of a 2000-ton crawler crane with high-performance wire rope solutions.

Are you finding that standard wire ropes just aren’t cutting it for your 2000-ton crawler crane’s heavy lifting needs? It’s incredibly frustrating when your equipment is held back by limitations that lead to downtime and potential safety issues, which is a common pain point when sourcing specialized components.

Why is High Quality Crane Rope Essential for Your Operations?

Are you tired of unreliable crane ropes causing downtime and safety concerns? It’s a common problem for many in heavy industry. We understand the frustration of facing constant equipment failures and the impact on project timelines.