Premium Wire Ropes with Closed Spelter Socket

High-performance wire ropes with closed spelter sockets, delivering secure anchorage, improved safety, and reliable lifting performance.

Open & Closed Spelter Socket Introduction

Open Spelter Socket (SOA) and Closed Spelter Socket (SOC) are high-strength wire rope end fittings designed for permanent terminations in critical lifting, hoisting, and structural applications. By using zinc speltering, the socket provides superior load transfer efficiency, excellent fatigue resistance, and long-term reliability.

Open Spelter Socket (SOA)

Open Spelter Sockets feature an open-ended design, allowing easier inspection of the wire rope inside the socket after assembly. This type is commonly used in crane hoisting systems, bridge construction, offshore lifting, and heavy-duty rigging applications where visual inspection is required.

Closed Spelter Socket (SOC)

Closed Spelter Sockets have a fully enclosed design, offering enhanced protection for the wire rope end against corrosion, mechanical damage, and environmental exposure. This structure provides higher safety assurance in permanent installations such as structural supports, suspension systems, and marine engineering projects.

Key Features

High breaking efficiency, typically achieving 100% of the wire rope minimum breaking load

Excellent fatigue performance under dynamic loading

Secure and permanent termination using zinc speltering

Suitable for critical lifting and structural applications

Surface Treatment

Hot-dip galvanized for enhanced corrosion resistance and extended service life

Standard

Manufactured in accordance with Federal Specification RR-S-550D (Type B)

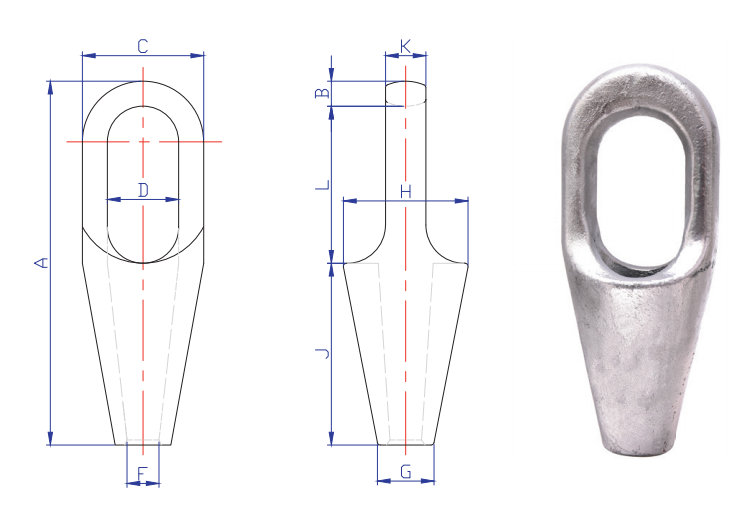

Parameters

| Type | Rope Dia(mm) | (in.) | MBL(T) | Size | Weight(kg) | |||||||||

| A | B | C | D | F | G | H | J | K | L | |||||

| AL-01 | 6-7 | 1/4 | 4.5 | 114.3 | 12.7 | 38.1 | 22.4 | 9.7 | 17.5 | 39.6 | 57.1 | 12.7 | 44.5 | 0.23 |

| AL-02 | 8-10 | 5/16–3/8 | 12 | 125.2 | 15.8 | 42.9 | 24.6 | 12.7 | 20.6 | 42.9 | 57.2 | 17.5 | 52.3 | 0.34 |

| AL-03 | 12-14 | 7/16–1/2 | 20 | 139.7 | 17.5 | 50.8 | 29.6 | 14.2 | 23.9 | 50.8 | 63.5 | 22.4 | 58.7 | 0.68 |

| AL-04 | 14-16 | 9/16–5/8 | 30.8 | 160.3 | 20.6 | 66.8 | 35.8 | 17.5 | 28.5 | 60.5 | 76.2 | 25.4 | 63.5 | 1.13 |

| AL-05 | 18 | 3/4 | 43.5 | 193.6 | 26.9 | 76.2 | 42.2 | 22.4 | 31.8 | 69.9 | 88.9 | 31.8 | 77.7 | 1.92 |

| AL-06 | 20-22 | 7/8 | 65.3 | 222.3 | 31.8 | 92.2 | 49.3 | 25.4 | 38.1 | 82.6 | 101.6 | 38.1 | 88.9 | 3.28 |

| AL-07 | 24-26 | 1 | 81.6 | 251 | 35.1 | 104.9 | 58.4 | 28.7 | 44.5 | 95.3 | 114.3 | 44.5 | 101.8 | 4.76 |

| AL-08 | 28-30 | 2001/1/8 | 100 | 279.4 | 38.1 | 114.3 | 65 | 31.8 | 50.8 | 104.9 | 127 | 50.8 | 114.3 | 6.46 |

| AL-09 | 32-35 | 1-1/4–1-3/8 | 136 | 308.1 | 41.4 | 127 | 71.4 | 38.1 | 57.2 | 121.6 | 139.7 | 57.2 | 127 | 9 |

| AL-10 | 38 | 1-1/2 | 170 | 354.1 | 49.3 | 136.7 | 81 | 41.4 | 69.9 | 133.3 | 152.4 | 63.5 | 152.4 | 13.2 |

| AL-11 | 40-42 | 1-5/8 | 188 | 384.3 | 54.1 | 146.1 | 82.6 | 44.5 | 76.2 | 139.7 | 165.1 | 69.9 | 165.1 | 16.3 |

| AL-12 | 44-48 | 1-3/4–1-7/8 | 268 | 438.2 | 55.6 | 171.5 | 95.3 | 50.8 | 79.5 | 162.5 | 190.5 | 76.2 | 192 | 26 |

| AL-13 | 50-54 | 2–2-1/8 | 309 | 501.7 | 62 | 193.8 | 111.3 | 57.2 | 95.3 | 187.5 | 215.9 | 82.6 | 223.8 | 35.8 |

| AL-14 | 56-60 | 2-1/4–2-3/8 | 360 | 546.1 | 69.9 | 215.9 | 127 | 66.8 | 104.9 | 210.4 | 228.6 | 92.2 | 247.7 | 47.6 |

| AL-15 | 64-67 | 2-1/2–2-5/8 | 424 | 596.7 | 79.3 | 241.3 | 139.7 | 73.2 | 114.3 | 235 | 247.7 | 101.6 | 269.8 | 63.5 |

| AL-16 | 70-73 | 2-3/4–2-7/8 | 549 | 644.4 | 79.3 | 273.1 | 158.8 | 79.3 | 124 | 258.8 | 279.4 | 124 | 285.8 | 99.8 |

| AL-17 | 75-80 | 3–3-1/8 | 656 | 688.9 | 85.6 | 292.1 | 171.5 | 85.9 | 133.4 | 292.1 | 304.8 | 133.4 | 298.5 | 125 |

| AL-18 | 82-86 | 3-1/4–3-3/8 | 750 | 743 | 101.6 | 311.2 | 184.2 | 92 | 146.1 | 311.2 | 330.2 | 146.1 | 311.2 | 142 |

| AL-19 | 88-92 | 3-1/2–3-5/8 | 820 | 787.4 | 101.6 | 330.2 | 196.9 | 98.6 | 160.3 | 330.2 | 355.6 | 158.8 | 330.2 | 181 |

| AL-20 | 94-102 | 3-3/4–4 | 1005 | 844.6 | 108 | 362 | 215.9 | 108 | 184.2 | 362 | 381 | 177.8 | 355.6 | 246 |