Crawler Crane Wire Rope

High Performance Steel Wire Ropes For Crawler cranes

Crawler cranes are used to lift heavy loads at high working heights and radii. Tasks such as installing wind turbines require extremely reliable high-performance wire ropes to safely and efficiently lift and lower loads, while maintaining high precision and maximum performance.

For the main hoist and auxiliary hoist applications of crawler cranes, Aulone offers high-performance wire ropes that are highly resistant to rotation and wear, exhibiting excellent winding characteristics during multilayer winding.

Aulone provides compacted and anti-rotation high-performance wire ropes with very high load capacity and flexibility, which have been successfully applied to various cranes. These ropes are equipped with tested rope end terminals, such as button sockets suitable for commercially available sockets. Rigorous testing and acceptance certificates prove the quality of the wire ropes and are part of our delivery process.

Tailored Crawler Crane Wire Ropes to Suit Your Needs!

At Aulone, we understand that every project demands the utmost in reliability and strength. That’s why we offer bespoke wire ropes designed specifically for crawler cranes, ensuring optimal performance and safety for your lifting operations.

Available Sizes: Ranging from 8mm up to 50mm.

Tensile Strength: 1770, 1960, 2160mpa.

Specifications on Offer: EN12385-4, GB8918, YB/T5359 and specific customer requirements.

Surface Treatments: Options including hot galvanized, ungalvanized, and stainless steel.

Special technology: Including multi-strand ropes, plastic impregnated, compacted, galvanized.

Structure: 35WX7, 35WXK7, 24WXK7, 19XK7, 15XK7, 8X26,8XK26,8XK26WS-EPIWRC,6XK36WS, 6XK36-IWRC etc

Lay types: RHLL, RHRL, LHLL, LHOL

Certifications: All our ropes come with BV and CE certifications, providing you with the assurance of quality and compliance with international standards.

Contact us today to learn more about how our high-quality, customizable wire ropes can enhance your crane operations.

Hoist Ropes

At Aulone, we specialize in providing high-quality hoist ropes designed specifically for crawler cranes. Our products are engineered to deliver exceptional performance, ensuring maximum safety and efficiency for all your lifting needs.

Boom hoist ropes

At Aulone, we pride ourselves on delivering top-quality boom hoist ropes tailored for crawler cranes. Our products are meticulously crafted to ensure superior strength, reliability, and safety, providing optimal performance for your lifting operation

Your Ultimate Guide to Acquiring Crawler Cranes Wire Rope

When it comes to acquiring the right wire rope for your crawler cranes, making an informed decision is crucial for the safety, efficiency, and longevity of your lifting operations. This guide provides comprehensive insights into selecting the best wire ropes tailored to your needs.

Table of contents

Chapt 1

Why Choose Aulone Crawler Crane Wire Rope?

When it comes to selecting wire ropes for your crawler cranes, Aulone stands out as a leading provider offering exceptional quality, performance, and support. Here are the key reasons why Aulone is the best choice for your wire rope needs:

1. Superior Strength and Durability

- High Load Capacity: Our wire ropes are engineered to handle substantial loads, ensuring reliable performance even in the most demanding lifting tasks. This makes them ideal for heavy-duty applications and ensures safety during operations.

- Wear Resistance: Constructed from premium-grade materials, our ropes offer exceptional resistance to abrasion and fatigue. This results in a longer service life and reduced maintenance costs, providing excellent value for money.

2. Enhanced Precision and Reliability

- Rigorous Quality Control: Each wire rope undergoes stringent testing and certification processes to meet the highest industry standards. This rigorous quality control guarantees that you receive a product that performs reliably and safely.

3. Customization and Versatility

- Tailored Solutions: At Aulone, we understand that every lifting operation is unique. Our wire ropes can be customized to meet your specific requirements, ensuring the perfect fit for your crawler cranes and various lifting applications.

- Versatile Applications: Our wire ropes are suitable for a wide range of environments, from construction sites to industrial projects. They are adaptable to different crane models and lifting needs, providing a versatile solution for your operations.

4. Safety and Efficiency

- Reduced Risk of Accidents: Designed with safety in mind, our ropes minimize the risk of operational failures. This creates a safer working environment for your team and reduces the likelihood of costly downtime due to accidents.

- Efficient Performance: High precision and reliability translate into more efficient lifting operations. This efficiency reduces downtime and increases productivity, ensuring your projects stay on schedule.

5. Supplier Advantages

- Expert Guidance: Our team of professionals provides personalized support, helping you select the ideal wire rope for your specific needs. We offer comprehensive after-sales assistance to ensure the optimal performance of your wire ropes.

- Competitive Pricing: We provide premium wire ropes at competitive prices, ensuring you receive excellent value without compromising on quality or performance.

- Reliable Supply Chain: With a robust and efficient supply chain, we ensure timely delivery of our products. This reliability keeps your projects on track and within budget.

Key Features of Aulone Crawler Crane Wire Ropes

- High Breaking Strength: Capable of withstanding extreme tension and load conditions, ensuring reliable performance in heavy-duty applications.

- Flexibility: Designed for easy handling and installation, reducing setup time and labor costs.

- Corrosion Resistance: Treated to resist corrosion, extending the lifespan of the ropes even in harsh environments.

Customer Support and Service

- Technical Support: Our team offers ongoing technical support to ensure the optimal performance of your wire ropes.

- Training and Workshops: We provide training sessions and workshops to educate your team on the best practices for using and maintaining our ropes.

- After-Sales Service: Our comprehensive after-sales service includes regular check-ups, maintenance advice, and prompt resolution of any issues.

Conclusion

Choosing Aulone for your crawler crane wire ropes means selecting a partner committed to delivering unmatched quality, reliability, and support. With our superior products and dedicated team, we ensure that your lifting operations are safe, efficient, and successful. Contact us today to learn more about our offerings and how we can enhance your crane operations.

Chapt 2

Selecting the Correct Tower Crane Rope Configuration

Choosing the right wire rope configuration for your crawler cranes is crucial for ensuring efficiency, safety, and longevity in your lifting operations. This guide provides detailed information on the appropriate wire rope configurations, including tensile strength, diameter, lay types, and rope surface options.

Key Factors to Consider

Load Capacity and Breaking Strength

- Assessing Load Requirements: Determine the maximum load your crawler crane will need to handle. Choose a wire rope with a breaking strength that exceeds this requirement to ensure safety and reliability.

- Safety Factor: Apply an appropriate safety factor to account for dynamic forces and unexpected load increases. This typically ranges from 3:1 to 5:1 depending on the application and industry standards.

Detailed Wire Rope Configurations

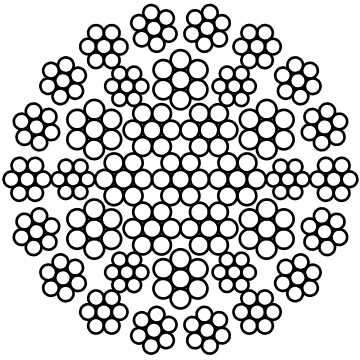

8XK26WS-IWRC

Description:

- Structure: Eight strands of 26 wires each, with an Independent Wire Rope Core (IWRC).

- Construction: Warrington Seale (WS).

- Tensile Strength: Typically ranges from 1770 N/mm² to 2160 N/mm².

- Lay Types: Right Regular Lay (RRL), Right Lang Lay (RLL), Left Regular Lay (LRL), Left Lang Lay (LLL).

- Rope Surface: Galvanized or Bright (Ungalvanized).

Advantages:

- Flexibility: The eight-strand construction offers excellent flexibility, making it suitable for applications requiring bending around sheaves and drums.

- Fatigue Resistance: The Warrington Seale design enhances the rope’s fatigue resistance, prolonging its service life under repeated bending stresses.

- Strength and Durability: With an IWRC, this rope provides high strength and resistance to crushing, making it ideal for heavy-duty lifting tasks.

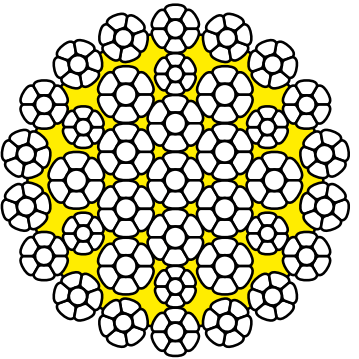

6XK36WS-IWRC

Description:

- Structure: Six strands of 36 wires each, with an IWRC.

- Construction: Warrington Seale (WS).

- Tensile Strength: Typically ranges from 1770 N/mm² to 2160 N/mm².

- Lay Types: Right Regular Lay (RRL), Right Lang Lay (RLL), Left Regular Lay (LRL), Left Lang Lay (LLL).

- Rope Surface: Galvanized or Bright (Ungalvanized).

Advantages:

- Balance of Strength and Flexibility: This six-strand configuration offers a good balance between tensile strength and flexibility, suitable for various lifting operations.

- Fatigue Resistance: The WS construction improves fatigue resistance, ensuring reliable performance under cyclic loads.

- Durability: The IWRC enhances the rope’s overall strength and resistance to internal wear.

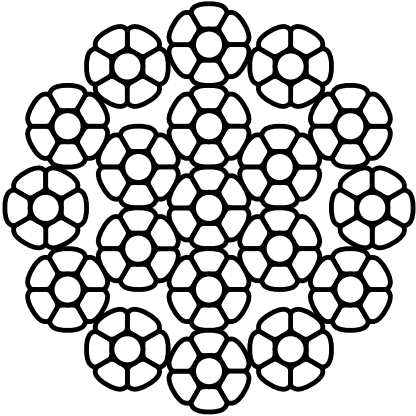

19XK7

Description:

- Structure: Nineteen strands of seven wires each.

- Construction: Rotation-resistant.

- Tensile Strength: Typically ranges from 1770 N/mm² to 2160 N/mm².

- Lay Types: Right Regular Lay (RRL), Left Regular Lay (LRL).

- Rope Surface: Galvanized or Bright (Ungalvanized).

Advantages:

- Rotation Resistance: Designed to minimize rotation under load, this structure is perfect for applications where load rotation must be controlled.

- Flexibility: Offers good flexibility, making it easier to handle and install.

- Safety: Reduces the risk of rope failure due to twisting, ensuring safer lifting operations.

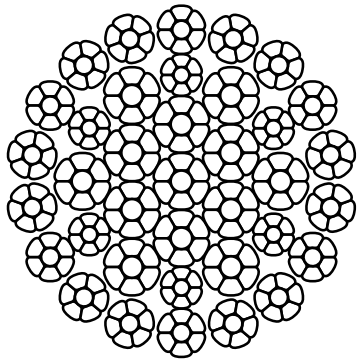

35WXK7 and 35WX7

Description:

- Structure: Thirty-five strands with seven wires each.

- Construction: Rotation-resistant.

- Tensile Strength: Typically ranges from 1770 N/mm² to 2160 N/mm².

- Lay Types: Right Regular Lay (RRL), Left Regular Lay (LRL).

- Rope Surface: Galvanized or Bright (Ungalvanized).

Advantages:

- High Rotation Resistance: These ropes provide superior rotation resistance, making them ideal for complex lifting scenarios where load stability is critical.

- Flexibility: The 35-strand configuration offers excellent flexibility, reducing wear and tear on the rope during operation.

- Load Distribution: The design distributes load evenly across the strands, enhancing the rope’s longevity and performance.

Maintenance and Inspection

Regular Inspections

- Conduct frequent inspections to identify signs of wear, corrosion, or damage. Replace ropes showing significant deterioration to maintain safety.

Proper Lubrication

- Lubricate wire ropes periodically to reduce friction and prevent corrosion. Use lubricants compatible with the rope material.

Correct Storage

- Store wire ropes in a cool, dry place away from direct sunlight and chemicals. Ensure they are coiled properly to avoid kinks and damage.

Conclusion

Selecting the correct wire rope configuration for your crawler cranes is critical for ensuring safe and efficient lifting operations. By considering factors such as load capacity, wire rope construction, core type, material, diameter, lay types, and rope surface, you can make an informed decision that meets your specific needs. Aulone offers a wide range of high-quality wire ropes tailored to various applications, providing the reliability and performance you require.

For expert guidance and customized solutions, contact Aulone today. Our team of professionals is ready to assist you in choosing the perfect wire rope configuration for your crawler cranes.

Feel free to reach out if you need further assistance or specific recommendations!

Chapt 3

Quality Assurance For Crawler Crane Wire Rope

For crawler cranes, which operate under heavy loads and challenging conditions, ensuring the quality of the wire rope is critical for safety and efficiency. Here’s a detailed look at the quality assurance process for crawler crane wire ropes:

Material Quality and Composition

- High Carbon Steel: Typically, wire ropes for crawler cranes are made from high carbon steel due to its excellent tensile strength and fatigue resistance.

- Alloy Elements: Addition of elements like manganese, chromium, and nickel can enhance the strength, ductility, and resistance to environmental wear.

- Coating Options: Zinc or epoxy coatings can be applied to protect against corrosion, especially in marine or corrosive environments.

Thorough Testing Regimes

- Tensile Strength Test: Ensures that the wire can support specific maximum loads without deformation or failure.

- Torque Balance Test: Measures the stability of the rope under torsion and its ability to return to its original state.

- Bend Fatigue Test: Critical for crawler crane ropes as they repeatedly pass over sheaves and drums; this test assesses the rope’s ability to endure bending stresses without failure.

Dimensional and Structural Accuracy

- Consistency in Diameter: Essential for the rope to fit pulleys and drum grooves accurately.

- Exact Lay Length: The distance in which a single strand makes one complete revolution around the rope is crucial for load distribution and overall stability of the rope.

- Core Integrity: The core supports the strands and maintains the structural integrity, tested for density and composition.

Inspection and Maintenance Protocols

- Initial Proof Load Test: Conducted post-manufacture to validate the design and load specifications.

- Continuous Monitoring Tools: Use of technologies like magnetic flux leakage and sonic testing to detect internal and external flaws.

- Routine Visual Checks: Regular inspections for signs of wear, corrosion, bird-caging, or kinking.

Certification and Traceability

- Quality Certificates: Each batch of rope should come with a certificate that details its compliance with the relevant standards.

- Batch Traceability: Should there be a defect, the ability to trace a rope back to its batch for further investigation is important.

Training and Handling

- Proper Handling: Training for operators on the correct handling and maintenance of wire ropes to prevent premature wear or damage.

- Installation Practices: Correct installation is critical to ensure the rope performs as expected without undue stress or misalignment.

By following these detailed procedures for quality assurance, you can ensure that tower crane wire ropes meet rigorous quality standards and contribute to safe and reliable crane operations.

Chapt 4

Crawler Crane Wire Rope Inspection and Maintenance

Inspection and maintenance of wire rope for crawler cranes are critical for ensuring the safe and efficient operation of the equipment. Here’s a detailed guide on how to conduct these processes effectively:

Inspection of Crawler Crane Wire Rope

Frequency of Inspections

- Daily Checks: Visual inspections should be carried out daily by the crane operator to identify any visible signs of wear or damage.

- Periodic Inspections: More thorough inspections should be scheduled monthly, quarterly, and annually, depending on the crane’s usage and the operating environment.

Key Inspection Points

- External Condition: Look for external wear, broken wires, corrosion, rust, and any deformations like kinks, birdcaging, or crushing.

- Internal Condition: Check for internal deterioration, which can be assessed by signs like popping or broken internal wires during rope flexing.

- End Terminations: Inspect the rope terminations for any signs of loosening or wear.

- Drum Winding: Check the winding on the drum to ensure the wire rope is spooling correctly without overlaps or gaps.

Tools and Techniques

- Visual and Tactile Methods: Use a combination of visual inspection and hands-on checking to feel for inconsistencies in the rope structure.

- Non-Destructive Testing (NDT): Techniques like magnetic particle inspection and ultrasonic testing can be used to find internal flaws.

- Rope Diameter Measurement: Measure the rope diameter at various points to detect stretching or wear, which could indicate weakening of the rope.

Documentation

- Inspection Records: Maintain detailed records of all inspections, including dates, findings, and any corrective actions taken.

- Compliance with Standards: Ensure all inspections meet industry standards such as ISO, ASTM, or specific crane manufacturer guidelines.

Maintenance of Crawler Crane Wire Rope

Regular Lubrication

- Purpose: Lubrication reduces friction among the wires and strands, helping to prevent internal wear and corrosion.

- Procedure: Apply lubricant that matches the original specification used by the manufacturer. Ensure the lubricant penetrates the internal structure of the rope.

Proper Handling and Usage

- Avoid Sharp Bends: Prevent the rope from bending sharply over sheaves or drums, which can cause fatigue and increase wear.

- Correct Spooling: Ensure the rope is evenly and tightly spooled on the drum to avoid loose layers that can lead to crushing and kinking.

Environment Management

- Protection from Elements: Store the crane in a way that minimizes exposure to harmful environmental conditions like extreme temperatures and corrosive atmospheres.

- Cleanliness: Keep the wire rope free from debris and contaminants that can accelerate wear.

Replacement Strategies

- Wear Limits: Establish clear criteria for when a rope should be retired, based on manufacturer’s recommendations and industry standards.

- Preventive Replacement: Consider replacing the wire rope before reaching these limits if the crane is used in severe conditions or carries critical loads.

Training

- Operator and Technician Training: Ensure all personnel are trained on proper rope handling, inspection techniques, and immediate actions to take if a problem is detected.

- Safety Training: Conduct regular safety drills and training sessions to ensure all team members understand the risks associated with wire rope failures.

By adhering to these comprehensive inspection and maintenance protocols, you can significantly extend the lifespan of wire ropes on crawler cranes while enhancing safety and reliability in operations.

Chapt 5

Crawler Cranes Wire Rope Replacement and Recycling

Replacing and recycling wire rope on crawler cranes involves a systematic approach to ensure safety and efficiency while also considering environmental responsibilities. Here’s a detailed guide on how to manage these processes effectively:

Detailed Replacement Process for Crawler Crane Wire Rope

Pre-Replacement Planning

- Risk Assessment: Conduct a thorough risk assessment to identify potential hazards associated with the wire rope replacement process.

- Tools and Equipment: Ensure all necessary tools and equipment, such as cranes for lifting the rope drum, wire rope grips, and appropriate personal protective equipment (PPE), are available and in good condition.

Detailed Replacement Steps

- Secure the Crane: Stabilize the crane, ensuring it is out of service and in a safe condition for maintenance.

- Unwind Old Rope: Carefully unwind the old wire rope from the drum. This should be done slowly to prevent sudden release of tension which could cause injury or damage.

- Inspect the Drum and Sheaves: Before installing new rope, inspect the drum and sheaves for any wear or damage. Any defects can significantly shorten the life of the new rope.

- Thread New Rope: Carefully thread the new wire rope through the crane’s sheaves according to the crane’s specific reeving diagram. Ensure that the rope lays correctly in the grooves without crossing over itself.

- Wind onto Drum: Wind the new rope onto the drum, ensuring that the layers lay neatly and tightly. This prevents the lower layers from being crushed by the upper layers under load.

- Attach End Fittings: Securely attach any end fittings, such as sockets or hooks, using the correct method (e.g., swaging or splicing).

Post-Replacement Testing and Adjustment

- Load Testing: Perform load testing under controlled conditions to verify the correct installation and operation of the wire rope.

- Adjustments: Make any necessary adjustments to the tension and spooling of the rope to optimize performance and lifespan.

Detailed Recycling Process for Crawler Crane Wire Rope

Preparation for Recycling

- Segmentation: Cut the wire rope into manageable lengths that can be easily transported. Use appropriate cutting tools like hydraulic cutters or angle grinders, ensuring all safety protocols are followed.

- Separation of Materials: Separate metal from any non-metallic materials like synthetic fibers or plastics used in the rope construction. This increases the purity and value of the scrap metal.

Choosing a Recycling Facility

- Certified Recyclers: Choose a recycling facility that is certified to handle industrial-grade metals and complies with local and national environmental standards.

- Transport: Arrange for the transport of the segmented rope to the recycling facility. Consider the logistics and costs involved, including any potential for bulk transport to reduce trips and carbon footprint.

Environmental Responsibility

- Documentation of Disposal: Maintain detailed records of the disposal process, including the amount of material recycled and the facility used. This documentation is crucial for compliance with environmental regulations and for corporate sustainability reporting.

- Sustainability Initiatives: Engage in initiatives that promote sustainability, such as investing in new technologies that reduce the environmental impact of crane operations or participating in industry-wide recycling programs.

- Financial Returns: Understand the financial aspects of recycling, including potential returns from scrap metal and the costs associated with cutting and transporting the wire rope.

- Compliance with Laws: Ensure compliance with all relevant local, state, and federal regulations regarding waste disposal and recycling to avoid fines and legal issues.

By following these detailed steps and considerations for both the replacement and recycling of wire rope on crawler cranes, organizations can ensure operational efficiency, safety, and environmental responsibility.

Chapt 6

Common Questions

Frequently Asked Questions

The cost of our Aulone wire ropes varies depending on the specifications and quantity you require. Could you please provide more details so we can give you an accurate quotation?

Regarding warranties and after-sales services, rest assured, we offer comprehensive support. Our products come with a warranty, and we provide after-sales service to ensure your satisfaction. We are committed to maintaining the quality of our products and assisting you throughout the entire process.

500m is acceptable.

It's based on order size and customization requirements. Generally speaking, it is 30 days,However, we strive to fulfill orders as quickly as possible while maintaining our quality standards. For specific timelines, please reach out directly to our sales team.

Please provide wire rope structure, diameter, lay types, galvanized or ungalvanized, tensile strength, min breaking force, length of a roll, termination condition.

Want to buy wire rope & sling?

We’re happy to assist you in finding the ideal rope for your application

86-15573139663

86-15363044363