35WXK7

High performance steel wire rope from Aulone for tower cranes.

High Performance Steel Wire Ropes For Tower Crane

Hoist Ropes for Tower Cranes

High-performance steel wire ropes for tower cranes are crucial for ensuring safety, reliability, and efficiency in construction and heavy lifting operations. These ropes are specially designed to handle the high demands and stresses involved in lifting heavy loads at great heights.

Lifting heavy loads with limited operating ranges requires tower cranes built specifically for that purpose. Because of that, the demands tower cranes place on high-performance steel wire ropes are unique. Aulone hoist ropes that resistance rotation allow you to lift and lower loads safely, efficiently, and reliably. When you lift, you need to position the load exactly where you want it without twisting it.

Aulone offers compacted and non-compacted hoist ropes that resist rotation for all common tower cranes. Naturally, we also provide the appropriate rope end terminations, as well as tests and acceptance certificates.

Tailored Tower Crane Wire Ropes to Suit Your Needs!

Are you looking for high-quality wire ropes for your tower cranes? We offer customized wire rope solutions designed to meet your specific requirements, ensuring optimal performance and safety for your lifting operations.

Available Sizes: Ranging from 8mm up to 50mm.

Tensile Strength: 1770, 1960, 2160mpa.

Specifications on Offer: EN12385-4, GB8918, YB/T5359 and specific customer requirements.

Surface Treatments: Options including hot galvanized, ungalvanized, and stainless steel.

Special technology: Including multi-strand ropes, plastic impregnated, compacted, galvanized.

Structure: 35WX7, 35WXK7, 24WXK7, 19X7, 19XK7, 15XK7, , 8X26,8XK26,8XK26WS-EPIWRC, 6X36WS,6XK36WS, 6X26, 6XK26, 4x39S+5FC etc

Lay types: RHLL, RHRL, LHLL, LHOL

Certifications: All our ropes come with BV and CE certifications, providing you with the assurance of quality and compliance with international standards.

To discuss your specific needs and get a quote for tailored tower crane wire ropes, reach out to our team of specialists at info@wireropes.net. Let us help you elevate your construction projects with our premium wire rope solutions!

Hoist Ropes

Aulone experts develop, manufacture, and provide innovative high-performance wire rope solutions for the global construction industry’s cranes.

For decades, the quality of our crane ropes has satisfied our customers because they meet the high demands of the construction industry. Direct and close collaboration with system and crane manufacturers is the cornerstone of our wire ropes, which possess all the technical characteristics required in the construction field. Our experts have extensive user knowledge and years of experience. Additionally, our wire ropes are designed to save our clients significant time and costs. By offering enhanced durability and reliability, our products reduce the frequency of replacements and maintenance, ensuring smoother operations and increased efficiency on all construction sites.

Trolley Rope

A trolley rope for a tower crane is a crucial component used in the mechanism that allows the crane’s trolley to move horizontally along the jib, which is the projecting arm of the crane. This rope is typically made of high-strength steel and is designed to handle heavy loads and resist the environmental stresses typical at construction sites, such as weather and constant movement.

The trolley rope works by connecting the trolley to the crane’s motor, which powers the movement back and forth along the jib. This allows the crane to place loads with precision across a horizontal plane. The rope needs to be both flexible and durable to cope with the dynamic loads and frequent bending around pulleys and drums. Regular inspections and maintenance are crucial to ensure safety and efficiency, as wear and damage to the rope can lead to operational failures or accidents.

If you have a specific aspect of the trolley rope for tower cranes you’re curious about, feel free to ask.

Boom Hoist Rope

The boom hoist rope for a tower crane is a crucial component responsible for lifting and lowering the boom of the crane. It needs to be strong, durable, and reliable to ensure the safety of operations.

Traditionally, boom hoist ropes for tower cranes are primarily made of high-strength steel wires. These wires are carefully constructed and woven together to create a rope capable of withstanding the heavy loads and stresses encountered during crane operations.

Steel wire ropes offer excellent strength, durability, and resistance to abrasion and corrosion, making them well-suited for the demanding conditions of construction sites. They are engineered to meet specific standards and requirements set by regulatory bodies and crane manufacturers.

Regular inspection and maintenance remain crucial for steel wire ropes to ensure their continued reliability and safety. Any signs of wear, corrosion, or damage should be promptly addressed to prevent potential accidents and maintain the crane’s operational efficiency.

Your Ultimate Guide to Acquiring Tower Crane Wire Rope

When purchasing wire rope for tower cranes, it’s essential to consider factors that ensure the rope’s performance, safety, and durability. Here’s a comprehensive guide to help you navigate through the process of acquiring the right wire rope for tower cranes:

Table of contents

Chapt 1

The material and construction of the tower crane wire rope

Tower cranes, essential for lifting heavy loads in the construction of tall buildings and structures, require wire ropes that are highly durable, strong, and capable of withstanding various environmental conditions. The material and construction of wire ropes used in tower cranes are specifically selected to meet these demands.

Material

- High Carbon Steel: Most tower crane wire ropes are made from high carbon steel, which provides the optimal combination of strength and flexibility. This material is capable of handling the high stress and dynamic loads experienced by cranes during operation.

- Galvanized Steel: Often, the steel wires are galvanized to protect against corrosion, especially in urban or coastal environments where corrosive elements like salt and pollutants can degrade metal. Galvanization involves coating the steel wires with a protective layer of zinc.

Construction

Strand Configuration: Tower crane wire ropes typically consist of several strands (commonly 6-8) twisted around a steel core. The core supports the strands, helping maintain their position and distributing the load evenly across the rope.

Lay Type:

Regular Lay: This is the most common lay type for tower cranes, where the strands are twisted in one direction and the wires within the strands in the opposite direction. This configuration provides good balance and stability, reducing the likelihood of the rope unlaying or kinking.

Lang Lay: Less common in tower cranes, but used when higher abrasion resistance and tensile strength are required. Both the strands and the wires are twisted in the same direction, increasing the rope’s contact with the load and reducing wear over time.

Rotation Resistance: For tower cranes, rotation-resistant wire ropes are often used. These ropes are designed to prevent the unintended spinning or rotation of the load, which is crucial for lifting and positioning materials accurately. Rotation-resistant ropes typically have a multilayer structure, with an outer layer of strands twisted in the opposite direction to the inner layers.

Pre-stressed and Pre-formed: Tower crane ropes are generally pre-stressed and pre-formed. Pre-stressing helps in removing the initial stretch in the new wire rope, while pre-forming ensures the wire strands and the core are in a stable shape before use, reducing the likelihood of deformation under load.

The choice of material and construction of wire ropes for tower cranes directly influences their performance and safety. Proper maintenance and regular inspections are also critical to ensure that these ropes continue to perform well throughout their service life.

Chapt 2

Selecting the Correct Tower Crane Rope Configuration

Compacted wire rope offers several advantages over traditional wire rope, making it a preferred choice for heavy-duty and high-stress applications. Here are the key benefits:

- Selecting the correct wire rope configuration for a tower crane is essential for ensuring efficient operation, maximum safety, and longevity of the rope. Here’s a detailed guide on how to choose the right tower crane rope configuration, taking into account several critical factors:

1. Assess the Crane Specifications

Load Capacity: Determine the maximum load the crane is designed to handle. This will influence the diameter and construction of the rope.

Drum and Sheave Size: Check the diameter of the drum and sheaves, as these will impact the minimum bending diameter of the rope.

2. Choose the Right Diameter

The diameter of the rope should be compatible with the sheave and drum diameters. A general rule is that the sheave diameter should be at least 20 times the diameter of the rope, and the drum should be at least 16 times the rope’s diameter.

3. Select Rope Construction

Detailed Overview of Specific Constructions

6xK36WS-IWRC: (6×36 Warrington-Seale with Independent Wire Rope Core)

- Configuration: This is a variant of the 6×36 class where the outer strands are made up of alternating large and small wires (Warrington), combined with two layers of wires (Seale) that have different diameters. This design provides a balance between abrasion resistance and fatigue resistance.

- Core: The Independent Wire Rope Core (IWRC) provides additional strength, reduces the amount of stretch, and increases the crushing resistance of the rope. This makes it ideal for heavy-duty lifting applications.

- Applications: Suitable for tower cranes that handle heavy loads or are used in high-capacity lifting. This type of rope offers good flexibility and is durable enough for both single-layer and multi-layer spooling on the drum.

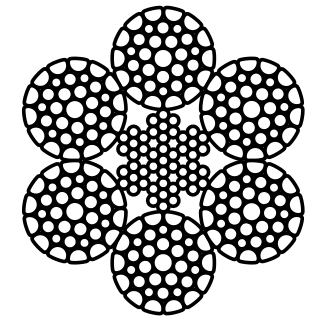

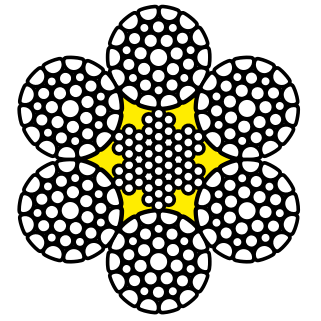

8xK26WS-IWRC: (8×26 Warrington-Seale with Independent Wire Rope Core)

- Configuration: This configuration also uses the Warrington-Seale pattern but typically involves eight strands, which provides higher flexibility and a smoother exterior, which is good for passing over sheaves and drums. The 26 wires per strand in this configuration give it a higher fatigue resistance.

- Core: Like the 6xK36WS, the IWRC in the 8xK26WS enhances the rope’s tensile strength and resistance to environmental factors, such as dirt and moisture, which might penetrate the rope.

- Applications: Often chosen for tower cranes requiring high flexibility and strength, particularly where precise load handling and smoother operation are critical. This rope type is particularly suitable for high-speed and high-lift operations.

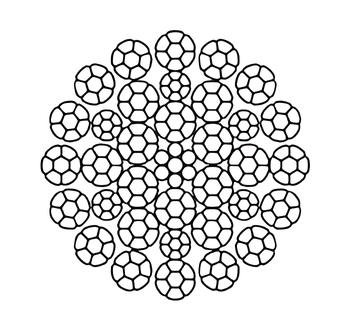

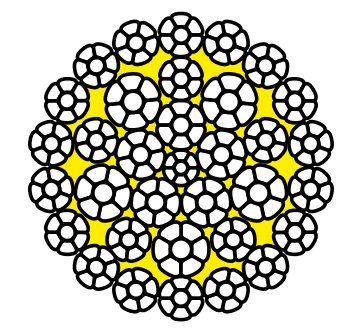

35WXK7 Wire Rope

- Construction: 35 Strands: The 35WXK7 wire rope features a compacted strand construction which typically means that it has a high fill factor, giving it greater contact area and thereby reducing internal wear and increasing rope life.

- Compacted Strands: The strands in this configuration are compacted, which reduces the rope’s diameter while maintaining the same mass. This compaction also provides a smoother external surface which improves abrasion resistance and increases the rope’s contact with sheaves and drums.

Warrington-Seale (WX): This pattern combines large outer wires for wear resistance with smaller inner wires to provide flexibility and fatigue resistance. - Rotation Resistant: The “K” in the designation indicates a non-rotating or rotation-resistant construction. This is achieved through the use of multiple layers of strands laid in opposite directions.

- 7 Core Strands: This indicates the presence of seven independent strands within the core, enhancing the core’s structural integrity and contributing to overall load-bearing capacity.

- Applications:The 35WXK7 wire rope is particularly suited for tower cranes where high lift capacities and high-speed operations are common. Its rotation-resistant features make it ideal for lifting loads that are sensitive to twisting, such as large prefabricated components.

This rope can also be beneficial in applications requiring precise load control and where extended rope life is essential due to difficult operational conditions or high-frequency usage.

4. Core Type

Fiber Core (FC): Provides more elasticity and flexibility, useful for cranes that require more damping of the load.

Independent Wire Rope Core (IWRC): Adds strength and resistance to crushing, ideal for higher capacity and multi-layer spooling operations.

5. Lay Direction

Regular Lay: More stable and less likely to untwist, which helps in multi-layer spooling on the drum.

Lang Lay: Provides better wear characteristics and increased contact area with sheaves and drums, suitable for single-layer spooling.

6. Rotation Resistance

Consider using rotation-resistant wire ropes if the crane lifts loads that are prone to spinning or twisting. These ropes are designed to minimize the rotational force that might otherwise cause the load to spin.

7. Galvanization

If the crane operates in a corrosive environment, consider galvanized ropes to enhance corrosion resistance.

8. Compliance with Safety Standards

Ensure that the chosen wire rope configuration complies with international safety standards like ISO, EN, ASTM, or others relevant to your location and industry.

9. Consultation with Experts

When selecting a wire rope for a tower crane, it’s advisable to consult with rope specialists or manufacturers. They can provide recommendations based on your specific crane model, operational conditions, and performance requirements.

10. Regular Inspection and Maintenance

Regardless of the rope type and construction selected, regular inspection and maintenance are crucial. Look for signs of wear, corrosion, kinking, and bird-caging, as well as checking for broken wires.

By carefully considering these factors and consulting with experts, you can select a wire rope that not only meets the operational demands of your tower crane but also enhances safety and efficiency.

Chapt 3

Quality Assurance For Tower Crane Wire Rope

Inspecting and maintaining tower cranes is crucial to ensure their safe and efficient operation. Here’s a general guideline for tower crane inspection and maintenance:

Incoming Material Inspection:

- Upon receipt of wire rope materials, conduct a thorough inspection to ensure they meet specifications.

- Verify the dimensions, chemical composition, and mechanical properties of the steel wires and core materials.

- Reject any materials that do not meet the required quality standards.

Manufacturing Process Control:

- Implement stringent process controls during wire rope manufacturing.

- Monitor parameters such as wire diameter, lay length, strand construction, and lubrication application.

- Conduct regular quality checks at different stages of the manufacturing process to detect and correct any deviations or defects.

Testing During Production:

- Perform in-process testing to verify the mechanical properties and integrity of wire ropes.

- Conduct tests such as tensile strength testing, elongation testing, and bend testing according to relevant standards.

- Reject any wire ropes that fail to meet specified quality criteria.

Final Inspection and Testing:

- Conduct a final inspection and testing of finished wire ropes before release for shipment.

- Perform comprehensive tests, including tensile strength testing, fatigue testing, and non-destructive testing (NDT) methods such as magnetic particle inspection or ultrasonic testing.

- Verify compliance with industry standards and customer specifications.

Certification and Documentation:

- Provide certification documents indicating compliance with relevant standards and specifications.

- Maintain detailed records of all quality assurance activities, including material inspections, manufacturing processes, test results, and certifications.

- Ensure traceability of wire rope batches or lots to facilitate tracking and recall procedures if necessary.

Installation Procedures:

- Develop standardized procedures for the installation of wire ropes on tower cranes.

- Train crane technicians on proper installation techniques, including correct rope tensioning, anchoring, and spooling onto drums.

- Ensure that all installation procedures comply with manufacturer recommendations and industry best practices.

Regular Inspection and Maintenance:

- Establish a schedule for regular inspection and maintenance of tower crane wire ropes.

- Inspect wire ropes before each crane operation for signs of wear, damage, or corrosion.

- Conduct periodic inspections using visual and non-destructive testing methods to assess the condition of wire ropes and identify any defects or degradation.

Quality Control Audits:

- Conduct periodic audits of manufacturing facilities and suppliers to evaluate compliance with quality standards and procedures.

- Review quality control measures, documentation practices, and corrective action processes to identify areas for improvement.

Continuous Improvement:

- Implement a system for feedback collection and analysis to identify opportunities for process improvement.

- Encourage collaboration between stakeholders, including manufacturers, suppliers, and end-users, to address quality issues and enhance product performance over time.

By following these detailed procedures for quality assurance, you can ensure that tower crane wire ropes meet rigorous quality standards and contribute to safe and reliable crane operations.

Chapt 4

Tower Crane Wire Rope Inspection and Maintenance

Inspecting and maintaining the wire ropes of a tower crane is crucial for ensuring safe and efficient crane operation. Wire ropes are subjected to significant stress and wear during crane operation, so regular inspection and maintenance are essential. Here’s a guide for wire rope inspection and maintenance:

Visual Inspection:

Conduct a visual inspection of the wire ropes before each crane operation.

Look for any signs of wear, such as broken wires, kinks, birdcaging (wire strands opening up), or corrosion.

Pay close attention to areas where the rope comes into contact with sheaves, drums, or other components, as these areas are more prone to wear.

Wire Rope Lubrication:

Regularly lubricate the wire ropes to minimize friction and prevent corrosion.

Use a suitable lubricant recommended by the rope manufacturer to ensure proper protection and longevity of the ropes.

Apply the lubricant evenly along the length of the wire ropes and work it into the strands.

Tension Inspection:

Check the tension of the wire ropes to ensure they are properly tensioned according to manufacturer specifications.

Use a tension gauge or dynamometer to measure the tension accurately.

Adjust the tension as necessary to maintain optimal performance and prevent excessive wear.

Non-Destructive Testing (NDT):

Periodically conduct non-destructive testing (NDT) on the wire ropes to detect internal defects or damage that may not be visible during visual inspection.

Common NDT methods for wire ropes include magnetic particle testing (MT), ultrasonic testing (UT), and eddy current testing (ECT).

End Fitting Inspection:

Inspect the end fittings and attachments of the wire ropes for signs of wear, deformation, or damage.

Ensure that end fittings are securely attached and properly aligned with the crane components.

Replacement of Worn Ropes:

Replace wire ropes that show signs of significant wear, damage, or fatigue.

Follow the manufacturer’s recommendations for rope replacement intervals based on usage and operating conditions.

Storage and Handling:

Properly store wire ropes when not in use to prevent damage from moisture, chemicals, or physical abrasion.

Avoid sharp bends or kinks when handling wire ropes, as these can cause internal damage and reduce the rope’s strength.

Training and Certification:

Ensure that personnel responsible for inspecting and maintaining wire ropes are properly trained and certified.

Provide training on proper inspection techniques, handling procedures, and safety precautions.

Documentation:

Keep detailed records of wire rope inspections, maintenance activities, and replacements.

Document any abnormalities or issues discovered during inspections and the actions taken to address them.

By following these guidelines and conducting regular inspections and maintenance, you can help ensure the safe and reliable operation of tower crane wire ropes. Regular maintenance not only prolongs the life of the ropes but also reduces the risk of accidents and downtime due to rope failure.

Chapt 5

Tower Crane Wire Rope Replacement and Recycling

Replacing tower crane wire ropes is essential to maintain the safety and reliability of crane operations. When replacing wire ropes, it’s also important to consider environmentally responsible disposal or recycling practices. Here’s a guide for wire rope replacement and recycling:

Assessment of Wire Rope Condition:

- Regularly inspect wire ropes for signs of wear, damage, or degradation.

- Determine the appropriate replacement interval based on usage, environmental conditions, and manufacturer recommendations.

- Consider factors such as broken wires, corrosion, reduction in diameter, or loss of strength when assessing the condition of wire ropes.

Planning for Replacement:

- Develop a replacement schedule based on the condition of the wire ropes and operational requirements.

- Coordinate replacement activities to minimize downtime and ensure continuity of crane operations.

- Determine the quantity and specifications of replacement wire ropes needed for each crane.

Selection of Replacement Wire Ropes:

- Choose high-quality wire ropes from reputable manufacturers or suppliers.

- Ensure that replacement wire ropes meet or exceed the specifications of the original ropes in terms of diameter, construction, strength, and performance characteristics.

Installation Procedures:

- Follow manufacturer guidelines and best practices for the installation of replacement wire ropes.

- Properly tension and secure the wire ropes to ensure safe and reliable crane operation.

- Train crane technicians on correct installation techniques to prevent damage or premature wear of the new ropes.

Disposal and Recycling:

- When removing old wire ropes, handle them with care to prevent injury or damage to property.

- Dispose of old wire ropes responsibly, taking into account environmental regulations and guidelines.

- Explore options for recycling wire ropes to minimize environmental impact and conserve resources.

- Contact local recycling facilities or scrap metal dealers to inquire about their acceptance of wire ropes for recycling.

Reuse or Repurpose:

- Consider whether old wire ropes can be reused or repurposed for other applications.

- For example, wire ropes may be suitable for use in agricultural or construction projects, as barriers, or for crafting and artistic purposes.

- Evaluate the condition and integrity of the old wire ropes to determine their suitability for reuse or repurposing.

Documentation and Record-Keeping:

- Maintain records of wire rope replacements, including dates, reasons for replacement, and details of the replacement process.

- Document disposal or recycling activities, including the methods used and any relevant environmental compliance documentation.

- Keep records of any reuse or repurposing efforts for old wire ropes.

By following these guidelines for wire rope replacement and recycling, you can ensure the safe and efficient operation of tower cranes while minimizing environmental impact and promoting sustainability.

Chapt 6

Common Questions

Frequently Asked Questions

The cost of our Aulone wire ropes varies depending on the specifications and quantity you require. Could you please provide more details so we can give you an accurate quotation?

Regarding warranties and after-sales services, rest assured, we offer comprehensive support. Our products come with a warranty, and we provide after-sales service to ensure your satisfaction. We are committed to maintaining the quality of our products and assisting you throughout the entire process.

500m is acceptable.

It's based on order size and customization requirements. Generally speaking, it is 30 days,However, we strive to fulfill orders as quickly as possible while maintaining our quality standards. For specific timelines, please reach out directly to our sales team.

Please provide wire rope structure, diameter, lay types, galvanized or ungalvanized, tensile strength, min breaking force, length of a roll, termination condition.

Want to buy wire rope & sling?

We’re happy to assist you in finding the ideal rope for your application

86-15573139663

86-15363044363