Premium Mining Wire Rope: Unmatched Strength and Reliability

Underground Mining Wire Rope

Every mine in the world is different, from the mineral being mined to the final hoisting of those minerals to the surface. Shaft hoisting is critical to the underground mining process. Every mine hoists minerals from different depths, different loads, and each under unique shaft conditions.

Most mines are in some of the harshest environments. The safety, reliability, and productivity of each shaft operation and the mine depend greatly on a strong, efficient, and safe hoisting setup. The mining rope plays a critical role. It needs to be constantly improved.

Aulone ensures a safe and efficient shaft operation by providing customers with custom ropes for their specific needs. We also provide the right service on site to ensure maximum productivity.

Drum Winders

Friction winders

Shaft sinking

Tailored Wire Ropes to Suit Your Needs!

Customized wire ropes for underground mining operations are essential for ensuring safety, efficiency, and durability. Whether it’s for hoisting, hauling, or other applications, having a wire rope tailored to suit specific requirements can make a significant difference in performance and longevity.

Available Sizes: Ranging from 12mm up to 90mm.

Tensile Strength: 1570, 1770,1870, 1960, 2160, and 2260mpa.

Specifications on Offer: EN12385-4, GB 8918, YB/T5359 and specific customer requirements.

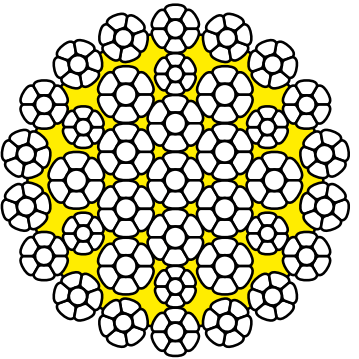

Surface Treatments: Options including hot galvanized, ungalvanized, and stainless steel.

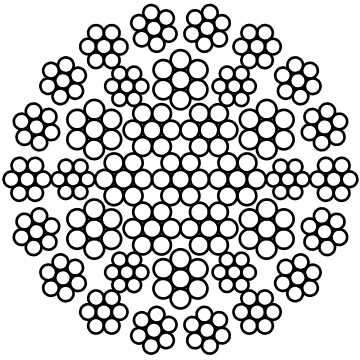

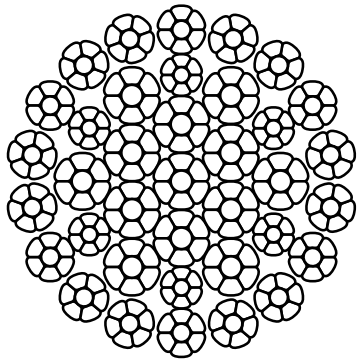

Special technology: Including multi-strand ropes, plastic impregnated, compacted, galvanized.

Structure: 35WX7, 35WXK7, 19X7, 19XK7, 8X26, 8XK26WS-IWRC, 8XK26WS-IWRC,8XK36WS-IWRC, 6XK36WS-EPIWRC,6XK36WS etc

Lay types: RHLL, RHRL, LHLL, LHOL

Certifications: All our ropes come with BV and CE certifications, providing you with the assurance of quality and compliance with international standards.

Overall, tailored underground mining wire ropes offer the advantage of optimized performance, longevity, and safety, contributing to the efficiency and success of mining operations while minimizing downtime and maintenance costs.

Beyond Simply Supplying Underground Mining wire rope

Beyond simply supplying underground mining wire ropes, Aulone often provide a range of additional services and products to support the mining operations more comprehensively. These can include:

Engineering and Design Services

Custom Rope Design:Tailoring wire ropes to specific mining applications and requirements.

Engineering ropes for unique challenges such as deep shaft mining or high-load applications.

System Integration:

- Designing complete hoisting and haulage systems that incorporate wire ropes.

- Ensuring compatibility with existing mining infrastructure and machinery.

Installation and Commissioning

Professional Installation:

- Expert teams to install wire ropes and associated equipment in mining operations.

- Ensuring correct installation to maximize safety and performance.

Commissioning Services:

- Testing and fine-tuning wire rope systems after installation.

- Ensuring all components function correctly and efficiently.

Maintenance and Inspection Services

Regular Inspections:

- Scheduled checks to identify wear, damage, or potential failure points in wire ropes.

- Using advanced technologies such as magnetic flux leakage (MFL) testing and ultrasonic testing.

Preventive Maintenance:

- Routine maintenance to extend the lifespan of wire ropes and prevent unexpected failures.

- Lubrication, tension adjustments, and replacing worn components.

Repairs and Splicing:

- On-site or off-site repair services for damaged wire ropes.

- Expertise in splicing techniques to join ropes or fix broken sections.

Training and Certification

Operator Training:

- Training programs for mining personnel on the proper handling, installation, and maintenance of wire ropes.

- Ensuring safety and efficiency in wire rope usage.

Safety Certifications:

- Providing certifications for compliance with safety standards and regulations.

- Ensuring that mining operations meet industry and governmental safety requirements.

Technical Support and Consulting

24/7 Technical Support:

- Offering round-the-clock assistance for troubleshooting and emergencies.

- Providing expert advice to resolve issues quickly and minimize downtime.

Consulting Services:

- Analyzing mining operations to recommend improvements in wire rope usage and maintenance.

- Advising on the latest technologies and best practices in wire rope management.

Product Innovation and Development

Research and Development:

- Investing in R&D to create more durable, efficient, and safer wire ropes.

- Developing new materials and coatings to enhance rope performance.

Customization and Prototyping:

- Working with mining companies to develop custom solutions for specific challenges.

- Prototyping new wire rope designs and systems for field testing.

Supply Chain Management

Logistics and Distribution:

- Efficient supply chain management to ensure timely delivery of wire ropes and related products.

- Managing inventory and stock levels to meet the demands of mining operations.

Global Sourcing:

- Sourcing high-quality materials from around the world to produce reliable wire ropes.

- Ensuring a steady supply of essential components despite market fluctuations.

Sustainability and Environmental Initiatives

Eco-friendly Materials:

- Developing wire ropes with environmentally friendly materials and processes.

- Reducing the ecological footprint of mining operations.

Recycling Programs:

- Offering programs for the recycling and proper disposal of old or damaged wire ropes.

- Promoting sustainable practices within the mining industry.

By providing these comprehensive services and products, companies can offer holistic solutions that not only supply underground mining wire ropes but also ensure their optimal performance, safety, and longevity in the mining environment.

Want to buy wire rope & sling?

We’re happy to assist you in finding the ideal rope for your application

86-15573139663

86-15363044363