Choosing the wrong wire rope for your drilling rig can cause big problems. This can lead to expensive downtime, safety risks, and project delays. Understanding a few key features is the first step.

The right special wire rope for a drilling rig must have excellent rotation resistance, high crush resistance, and a strong core. These features ensure it can handle the intense dynamic loads and harsh environment of drilling operations safely.

I remember a client who was using a standard rope on their rig. It failed much sooner than expected. The downtime cost them more than the savings on the rope. After that, we switched them to a specialized drilling line.

What Unique Stresses Do Drilling Rig Ropes Face?

Drilling operations are tough on equipment, especially wire ropes. Have you ever wondered what makes these conditions so demanding? It’s more than just lifting a heavy load from one place to another.

Drilling rig ropes constantly face four main stresses: high tension, severe abrasion against drums and sheaves, crushing pressure on the drum, and intense vibrations. These combined forces can quickly degrade a standard rope.

Let’s dive deeper into each of these challenges. A wire rope on a drilling rig isn’t just hanging there. It’s in constant motion, working in a dirty and demanding environment. Understanding these specific stresses shows why a standard crane rope often isn’t enough for the job.

High Tensile and Dynamic Loads

A drilling line supports the entire weight of the drill string. This load is already very heavy. But the load is not static. The rope experiences sudden changes in tension as drilling starts and stops. This is called dynamic loading. It puts much more stress on the rope than a simple dead weight. The rope needs a very high breaking strength to handle these shock loads without failing.

Abrasion and Wear

The wire rope is always rubbing against other surfaces. It runs over sheaves (the pulley wheels) and wraps around the winch drum. In a drilling environment, mud and grit often get on the rope. This creates a sandpaper-like effect. It wears down the outer wires of the rope. So, the rope must be designed to resist this constant abrasion.

Crushing and Deformation

When the rope is wound onto the drum, it forms multiple layers. The upper layers press down hard on the layers below them. This pressure can crush the rope. It can change the rope’s shape from round to oval. A crushed rope is a weak rope. The rope’s construction must be strong enough to resist this pressure, especially on multi-layer winch systems.

Bending Fatigue

The rope is constantly bending and straightening as it passes over sheaves and onto the drum. Each bend cycle creates stress inside the wires. Over thousands of cycles, these stresses can cause the individual wires to break from fatigue. A good drilling rope needs to be flexible enough to handle repeated bending without breaking down too quickly.

Here is a summary of the stresses a drilling rope endures:

| Stress Type | Description | Impact on Rope |

|---|---|---|

| Dynamic Loads | Sudden changes in tension from drilling actions. | Requires high tensile strength and shock resistance. |

| Abrasion | Rubbing against sheaves, drums, and grit. | Wears down outer wires, reducing rope diameter and strength. |

| Crushing | Pressure from multiple layers of rope on the drum. | Deforms the rope’s shape, leading to internal damage. |

| Bending Fatigue | Repeated bending and straightening over sheaves. | Causes individual wires to break over time. |

Which Wire Rope Constructions Are Best for Drilling Operations?

Now that we know the challenges, how do we find a rope built to handle them? The secret is in the rope’s construction. Not all wire ropes are made the same way.

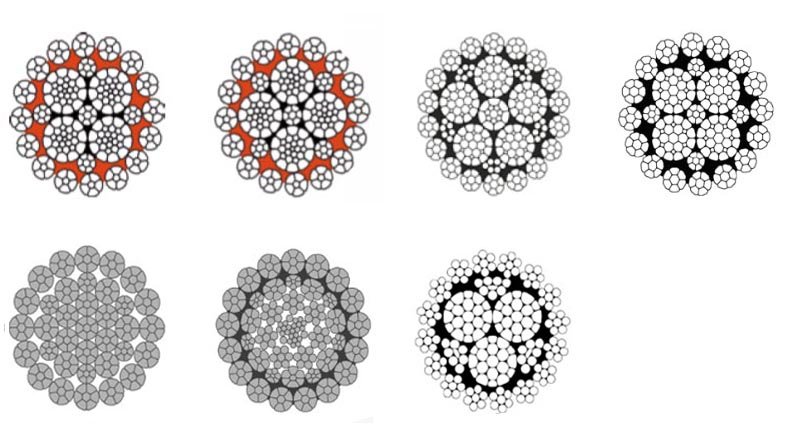

The best wire rope constructions for drilling are rotation-resistant and often compacted. Ropes like 19×7 or 35×7 are excellent because they resist twisting under load and have a high breaking strength and crush resistance.

The construction refers to how the wires and strands are twisted together to form the final rope. A simple construction like 6×19 might be good for a garage door, but it’s not right for a million-dollar drilling operation. Let’s look at why certain designs are superior for this job.

Standard Ropes vs. Rotation-Resistant Ropes

A standard wire rope, like a 6×19 or 6×36 class rope, has a natural tendency to twist or unlay when it’s under load. This is because all its strands are twisted in the same direction. For many applications, this isn’t a problem. But in drilling, a spinning load is dangerous and inefficient.

Rotation-resistant ropes are designed differently. They have multiple layers of strands. The inner layers are twisted in one direction, and the outer layers are twisted in the opposite direction. These opposing forces cancel each other out. This keeps the rope stable and greatly reduces the tendency to spin.

Common Constructions for Drilling Lines

Choosing the right construction involves balancing strength, flexibility, and resistance to wear. Here are a few common options you will see for drilling applications.

| Construction | Category | Key Characteristics | Best Use Case |

|---|---|---|---|

| 8 x 25 | Lang Lay, Compacted | Good flexibility, high abrasion resistance. | Good for single-layer spooling where rotation is less of a concern. |

| 19 x 7 | Rotation-Resistant | Resists spinning under load. Less flexible than other options. | Shallow to medium depth drilling where load spinning is a primary concern. |

| 35 x 7 | Rotation-Resistant, Compacted | Excellent rotation resistance, high strength, good crush resistance. | Deep drilling, heavy-duty applications, multi-layer spooling. |

| Compacted Ropes | Special Finish | Strands are flattened, increasing surface area and strength. | Any drilling application where crush resistance and longer life are needed. |

As you can see, a rope like 35×7 is a very popular and effective choice. It combines the benefits of being rotation-resistant with the durability of a compacted design. This makes it a great all-around performer for demanding drilling work.

How Do Compaction and Plastic Impregnation Improve Performance?

We have mentioned “compacted” ropes. We can also add another feature: plastic impregnation. These are special manufacturing processes. Are they just marketing terms, or do they offer real benefits for your drilling rig?

Compaction increases a rope’s strength and crush resistance. Plastic impregnation locks in lubricant, prevents internal corrosion, and further improves fatigue life. Both significantly extend a rope’s service life in harsh environments.

These are not just small upgrades. They fundamentally change how the rope performs and how long it lasts. In my experience, investing in a rope with these features pays for itself through reduced downtime and longer replacement intervals. Let’s break down exactly what they do.

What is a Compacted Wire Rope?

A compacted rope is a wire rope that goes through a special process after it is manufactured. The rope or its strands are passed through a die or rollers. This flattens the outer surface of the strands.

- Increases Metallic Area: Compaction squeezes out the empty spaces between the wires. This means there is more steel in the same diameter of rope. More steel means more strength. A compacted rope can be 10-15% stronger than a non-compacted rope of the same size.

- Improves Crush Resistance: The flattened, smooth surface of the strands provides better support on the winch drum. It distributes pressure more evenly, making the rope highly resistant to crushing on multi-layer drums.

- Reduces Abrasion: The smooth surface also means there is more contact area between the rope and the sheave or drum. This reduces wear on both the rope and your equipment.

What is Plastic Impregnation (PI)?

Plastic impregnation is another advanced feature. During manufacturing, a special polymer is injected into the rope. This plastic completely fills the empty spaces between the strands and the core.

Benefits of Plastic Impregnation

- Locks in Lubrication: The plastic seals the factory lubricant inside the rope. This ensures the core and inner wires stay lubricated for the entire life of the rope, which is critical for reducing internal friction and wear.

- Keeps Contaminants Out: The plastic layer acts as a barrier. It prevents mud, sand, water, and chemicals from getting inside the rope and causing internal corrosion and abrasion.

- Improves Structural Stability: The plastic helps the strands and wires maintain their correct positions. This improves the rope’s stability and fatigue life, especially during repeated bending cycles.

Here is a simple comparison:

| Feature | Standard Rope | Compacted PI Rope |

|---|---|---|

| Surface | Round outer wires, more gaps. | Smooth, flat surfaces, fewer gaps. |

| Strength | Standard breaking load. | 10-15% higher breaking load. |

| Crush Resistance | Moderate. | Excellent. |

| Internal Lubrication | Can dry out or get contaminated over time. | Sealed in for life. |

| Corrosion Resistance | Prone to internal and external corrosion. | Highly resistant to internal corrosion. |

| Service Life | Standard. | Significantly longer. |

What Standards and Certifications Should You Look For?

You have selected the right construction and features. Now, how do you verify the quality? You cannot tell a rope’s quality just by looking at it. This is where standards and certifications become extremely important.

For drilling ropes, you should look for compliance with international standards like EN12385-4 or API 9A. Also, ask for third-party inspection certificates from bodies like DNV, ABS, or BV to ensure an unbiased quality guarantee.

I have worked with many purchasing managers. They all have one thing in common: they cannot afford a product failure. Certifications are their proof of quality. It’s an assurance that the rope has been tested and meets strict safety and performance criteria. It’s not just a piece of paper; it’s peace of mind.

Key Industry Standards

Standards define the minimum requirements for a product. They cover everything from the raw material quality to the manufacturing process and testing procedures. For special wire ropes, two standards are very common.

- EN12385-4: This is a European standard for steel wire ropes. It is very detailed and widely respected globally. It specifies requirements for ropes used in heavy-duty applications, including cranes and drilling rigs.

- API 9A: This is a standard from the American Petroleum Institute. It specifically covers the specification for wire rope used in the oil and gas industry. If you work in this sector, compliance with API 9A is often mandatory.

Third-Party Certifications (Class Societies)

A manufacturer can claim to meet a standard. But a certificate from a trusted third party proves it. These organizations, often called Class Societies, are independent inspectors. They witness the manufacturing and testing of the rope to ensure it meets the standards.

When you buy a rope, you can request a certificate from one of these bodies. It adds an extra layer of trust and is often required for insurance or regulatory purposes.

Here are some of the most recognized certification bodies:

| Certification Body | Abbreviation | Main Focus | Why It Matters for You |

|---|---|---|---|

| Det Norske Veritas | DNV | A global quality assurance and risk management company, very strong in marine and offshore sectors. | A DNV certificate is a gold standard for quality, especially for offshore drilling. |

| American Bureau of Shipping | ABS | Focuses heavily on the marine and offshore industries, particularly in the Americas. | Guarantees the rope is suitable and safe for use on offshore platforms and vessels. |

| Bureau Veritas | BV | A French company that provides testing, inspection, and certification services across many industries. | A globally recognized mark of quality and compliance. |

| Russian Maritime Register of Shipping | RMRS | A leading classification society focusing on equipment for ships and marine structures in Russia. | Essential for projects operating in Russia or with Russian partners. |

When we provide a wire rope, we can supply these certificates if you need them. It’s part of our commitment to delivering a product you can trust completely.

Conclusion

Choosing the right special drilling rope is vital. It improves safety, extends service life, and boosts your rig’s efficiency, saving you money in the long run.