Are you worried about your vessel’s safety at berth? A failed mooring rope can lead to catastrophic damage and financial loss. Understanding the key factors is essential for prevention.

The most crucial factors are the rope’s Minimum Breaking Load (MBL), construction type, and material quality. It must meet both vessel design requirements and international standards like EN-12385 to ensure safety.

I once had a new client who focused only on the lowest price. Their first ropes failed inspection after just six months. We showed them how quality materials and correct specifications prevent these costly, dangerous mistakes.

What Are The Main Types of Mooring Wire Ropes?

Choosing a mooring rope is like picking a tool for a job. The rope’s internal design, or construction, determines how it performs. Let’s look at the most common and effective designs.

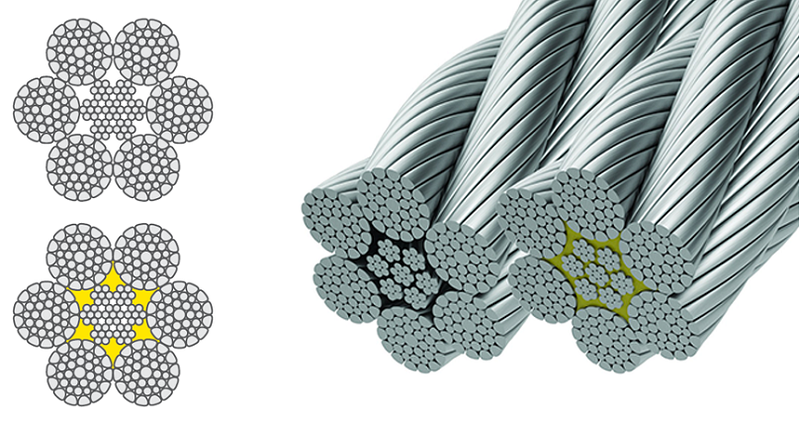

The most common and reliable mooring ropes use a 6-strand construction, such as 6x36 WS or 6x41 WS, with an Independent Wire Rope Core (IWRC). This design offers the best mix of strength, flexibility, and fatigue resistance for mooring operations.

Understanding Rope Construction

A wire rope is more than just twisted steel. It’s an engineered machine with several parts.

- Wires: Individual steel filaments that form a strand.

- Strands: A group of wires twisted together around a central element.

- Core: The center of the rope that supports the strands. For mooring, this is almost always an

Independent Wire Rope Core (IWRC).

The way these wires and strands are arranged defines the rope’s characteristics.

Common Mooring Rope Constructions

Different constructions are suited for different conditions. For mooring, you need a balance. You need the rope to be flexible enough to handle, but strong and resistant to abrasion from fairleads and winches.

| Construction | Main Characteristics | Primary Mooring Use |

|---|---|---|

6x36WS+IWRC | High flexibility, very good fatigue resistance. | General purpose mooring, cranes, frequent handling. |

6x41WS+IWRC | Higher steel content, better crush and abrasion resistance. | High-tension winches, situations with high pressure on the drum. |

6x49SWS+IWRC | More wires, very flexible. | Good for smaller diameter ropes or where flexibility is key. |

6x25FI+IWRC | Less flexible, but very good abrasion resistance. | More static lines, less frequent handling needed. |

Why the Core Matters: IWRC vs. Fiber Core

The core is the rope’s foundation.

- Fiber Core (FC): Made from natural or synthetic fibers. It offers great flexibility but is easily crushed and stores less energy. It is not recommended for standard mooring lines.

- Independent Wire Rope Core (IWRC): It is a small wire rope itself, acting as the core. It provides excellent strength, minimal stretch, and superior crush resistance on winch drums. For mooring applications,

IWRCis the industry standard for safety and performance.

How Do You Calculate the Required Mooring Rope Strength?

Guessing the strength of your mooring rope is not an option. It’s a precise calculation that ensures the safety of the crew, vessel, and port. This calculation is a fundamental part of maritime safety.

You determine the required strength by first identifying your vessel’s “Ship Design MBL,” which is based on its Equipment Number (EN). The MBL of the new rope must then meet or exceed this value, a rule enforced by class societies.

Dive Deeper: A Step-by-Step Guide to Strength Calculation

Following this process is not just good practice; it is often required by your insurance and by port authorities.

Step 1: Find Your Vessel’s Equipment Number (EN)

The Equipment Number (EN) is a figure calculated by a classification society (like ABS, DNV, etc.). It is based on the vessel’s size, displacement, and profile exposed to wind. You can find this number in your vessel’s classification documents. It is the starting point for all mooring equipment calculations.

Step 2: Determine the “Ship Design MBL”

Once you have the EN, you can find the corresponding “Ship Design MBL” from tables provided by your classification society. The Ship Design MBL is the minimum breaking load that the mooring system as a whole is designed to withstand.

Here is a simplified example table to show the relationship:

| Equipment Number (EN) | Example Ship Design MBL (tonnes-force) |

|---|---|

| 500 | 120 t |

| 1000 | 210 t |

| 2000 | 350 t |

| 4000 | 585 t |

| Disclaimer: This table is for illustration only. You must consult your vessel’s official documentation for exact values. |

Step 3: Select Your Mooring Rope’s MBL

The rope you purchase must have an actual Minimum Breaking Load (MBL) that meets the requirement. Industry best practices, like those from OCIMF, recommend that the mooring line’s MBL is equal to the Ship Design MBL. The rope certificate must prove this breaking load. When we manufacture ropes, every coil is tested to ensure it meets or exceeds this certified MBL. This is a critical quality control step.

Why Is Galvanization So Important for Mooring Ropes?

Your mooring ropes live in a harsh world. They are constantly exposed to saltwater, sun, and changing weather. Without protection, steel rusts and weakens quickly. This is where galvanization becomes essential.

Galvanization is a process that coats steel wires with a layer of zinc. This zinc layer corrodes first, sacrificing itself to protect the steel from rust. This dramatically increases the rope’s service life and maintains its strength in a marine environment.

Dive Deeper: More on Corrosion Protection

Corrosion is the number one enemy of a wire rope. It can happen on the outside (external corrosion) and on the inside (internal corrosion). Internal corrosion is particularly dangerous because you cannot see it.

How Does Galvanization Work?

The process is simple but effective. When steel and zinc are in contact in a corrosive environment (like saltwater), the zinc acts as a “sacrificial anode.” It corrodes away instead of the steel. This electrochemical protection continues even if the zinc coating gets minor scratches.

Galvanization Grades for Ropes

There are different thicknesses of zinc coating available.

- Class A Galvanization: This is a heavy-duty coating. It provides the longest-lasting protection and is the standard for mooring lines, anchor lines, and any rope with constant saltwater exposure. We recommend Class A for all customers in marine industries.

- Bright (Ungalvanized): These ropes have no protective coating. They will rust very quickly in a marine environment. They are cheaper but are a poor choice for mooring due to their short lifespan and safety risk.

This comparison table makes the choice clear.

| Feature | Galvanized Rope (Class A) | Ungalvanized (Bright) Rope |

|---|---|---|

| Corrosion Resistance | Excellent | Very Poor |

| Service Life in Marine Use | Long | Very Short |

| Long-Term Cost | Lower (fewer replacements) | Higher (frequent replacements) |

| Recommended Use | All mooring & marine applications | Dry, indoor environments only |

A few years ago, a customer from Indonesia bought bright ropes from another supplier to save money. Within a year, rust was so bad they failed inspection. They have been buying Class A galvanized ropes from us ever since and have had no issues.

What Certifications Must Your Mooring Ropes Have?

A certificate is your proof that a rope is safe and meets specifications. It is not just a document; it’s a vital part of your vessel’s compliance. Arriving in port without the correct papers can cause serious delays and fines.

Every mooring rope must have a manufacturer’s test certificate stating its MBL, size, and compliance with a standard like EN 12385-4. For international trade, a third-party certificate from a classification society like DNV, ABS, or RMRS is often mandatory.

Dive Deeper: Navigating Certifications

Understanding certificates helps you buy with confidence and operate with compliance.

### Manufacturer’s Test Certificate (MTC)

This is the most basic level of certification. At our factory, we issue an MTC with every rope we produce. It is our guarantee to you. It should include:

- Manufacturer’s Name (e.g., Aulone)

- Rope Diameter and Length

- Construction (

6x36 WS+IWRC, for example) - Minimum Breaking Load (MBL) in kN or tonnes

- Applicable Standard (e.g.,

EN 12385-4) - A unique identification number for traceability

The Role of Third-Party Classification Societies

These are independent organizations that create and enforce technical standards for the construction and operation of ships. The most well-known are:

- DNV (Det Norske Veritas)

- ABS (American Bureau of Shipping)

- LR (Lloyd’s Register)

- BV (Bureau Veritas)

- RMRS (Russian Maritime Register of Shipping)

When a client needs a class certificate, a surveyor from one of these societies will visit our factory. They will witness our quality control and our break-testing procedures for that specific order. They then issue a certificate that is trusted globally.

Why Third-Party Certification is Worth It

- Compliance: Port State Control officers worldwide check for these certificates. Without them, your vessel can be detained.

- Insurance: Your H&M (Hull & Machinery) insurer may require class-certified ropes, especially for newer or larger vessels. A claim could be denied without it.

- Quality Assurance: It provides independent proof that the rope you bought truly meets the strength it claims. For a purchasing manager, this removes all doubt about product quality. We can provide certificates from any major class society if our client needs them.

Conclusion

Choosing the right mooring rope means understanding MBL, construction, coatings, and getting the right certificates. Proper maintenance then ensures safety and a long service life for your investment.