I know how frustrating it can be when a project is delayed because of the wrong rope. Lifting operations are risky, and safety matters. Choosing the right rope is critical for efficiency and protection.

Luffing ropes like 8XK26WS-IWRC, 6XK36WS-IWRC, 8XK26WS-EPWIRC, and 10-strand wire ropes offer high tensile strength, smooth operation, and certified safety for cranes and heavy lifting applications.

I once had a project where a luffing crane kept snapping ropes. It caused days of delay and extra cost. From that moment, I realized understanding rope structures and certifications is as important as the crane itself. You will see why these ropes are the best choice.

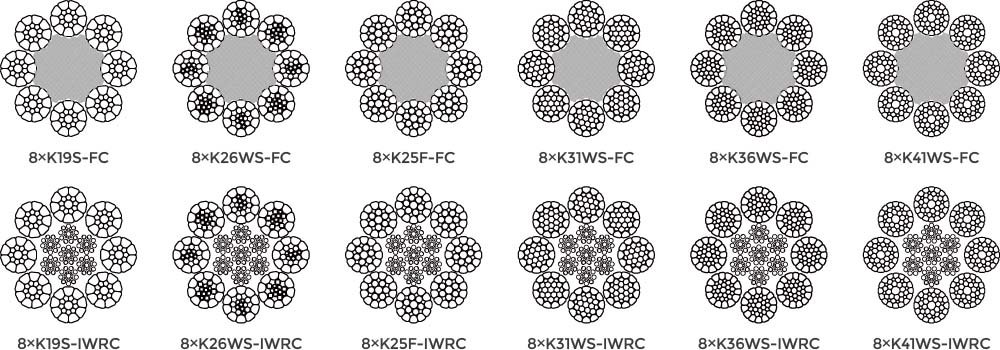

What Are the Common Structures of Luffing Ropes?

Luffing ropes come in different constructions. Each has its own advantages depending on crane type, load, and environment. Choosing the wrong rope can lead to faster wear, accidents, or downtime.

8XK26WS-IWRC, 6XK36WS-IWRC, 8XK26WS-EPWIRC, and 10-strand wire ropes are the most reliable structures. They provide strength, rotation resistance, and long service life.

Luffing Rope Structures

8XK26WS-IWRC

- 8 strands with K-lay construction

- Independent wire rope core (IWRC) for strength

- Excellent for cranes requiring rotation resistance

- Works well in tower cranes and construction sites

I remember using 8XK26WS-IWRC on a city crane project. The rope handled every lift smoothly, even with sudden load shifts. It saved us from constant maintenance checks.

6XK36WS-IWRC

- 6 strands with 36 wires per strand

- Extra fatigue resistance

- Perfect for large cranes with frequent lifting

- Longer service life in continuous operations

On one large mining crane, we switched from a standard 6-strand to 6XK36WS-IWRC. The difference was clear: fewer frays, smoother lifts, and more confidence in heavy operations.

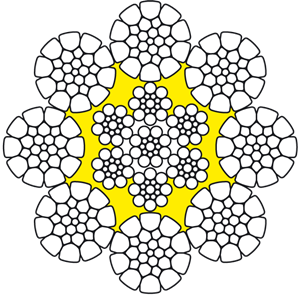

8XK26WS-EPWIRC

- Plastic-impregnated to reduce internal friction

- High wear resistance

- Ideal for marine cranes or wet environments

- Maintains performance under moisture

I’ve seen clients in ports choose EPWIRC ropes. Even after months in saltwater, the ropes performed reliably without corrosion or rope core issues.

10-Strand Wire Rope

- 10 strands for higher load capacity

- Great for heavy-duty lifting

- Available in galvanized or stainless steel

- Reduces risk of snapping under extreme weight

| Rope Type | Strands | Core Type | Key Advantage | Application |

|---|---|---|---|---|

| 8XK26WS-IWRC | 8 | IWRC | Rotation resistance | Tower cranes |

| 6XK36WS-IWRC | 6 | IWRC | Fatigue resistance | Large cranes |

| 8XK26WS-EPWIRC | 8 | EPWIRC | Reduced internal friction | Marine cranes |

| 10-Strand Wire | 10 | IWRC | High load capacity | Heavy lifting projects |

How to Choose the Right Luffing Rope for Your Project?

Each project has its own lifting needs. Using the wrong rope risks downtime, accidents, and higher costs.

Choose based on crane type, lifting frequency, environmental exposure, and required load. 8XK26WS-IWRC works best for rotation-sensitive lifts. EPWIRC ropes excel in wet conditions. 10-strand ropes handle very heavy loads.

Selection Criteria

Crane Type

Different cranes require different rope constructions. Tower cranes need rotation resistance, so IWRC ropes are ideal. Luffing cranes with frequent movement benefit from EPWIRC ropes with lower internal friction.

Lifting Frequency

High-frequency lifts wear ropes faster. Using 6XK36WS-IWRC reduces fatigue and prolongs rope life.

Environmental Conditions

Marine or wet environments demand corrosion resistance. Plastic-impregnated or galvanized ropes prevent rust and extend service life.

Load Requirements

High load operations need stronger ropes. 10-strand ropes provide higher breaking loads and safer lifting.

| Factor | Recommendation | Reason |

|---|---|---|

| Crane Type | IWRC ropes | Best rotation resistance |

| Lifting Frequency | 6XK36WS-IWRC | Reduces fatigue |

| Environment | EPWIRC, galvanized or plastic-coated | Corrosion resistance |

| Load Capacity | 10-strand wire ropes | Handles heavy loads safely |

Why Certification and Quality Control Matter in Luffing Ropes?

I’ve seen buyers compromise on certification. The wrong rope can fail inspection or break in operation. Safety is non-negotiable.

Check for EN12385-4 compliance, BV, CE, RMRS, DNV, or ABS certification. High-quality ropes prevent accidents, downtime, and costly replacements.

Certification

- EN12385-4: European standard ensures minimum breaking load.

- BV & CE: Guarantee industrial safety compliance.

- RMRS & DNV: Marine certification for reliability in harsh conditions.

- ABS: Offshore and class-certified ropes for extreme load handling.

| Certification | Scope | Why It Matters |

|---|---|---|

| EN12385-4 | Lifting ropes | Safety and durability |

| BV & CE | Industrial machinery | Compliance with safety laws |

| RMRS & DNV | Marine applications | Corrosion resistance, reliability |

| ABS | Offshore & shipping | High load & marine standard |

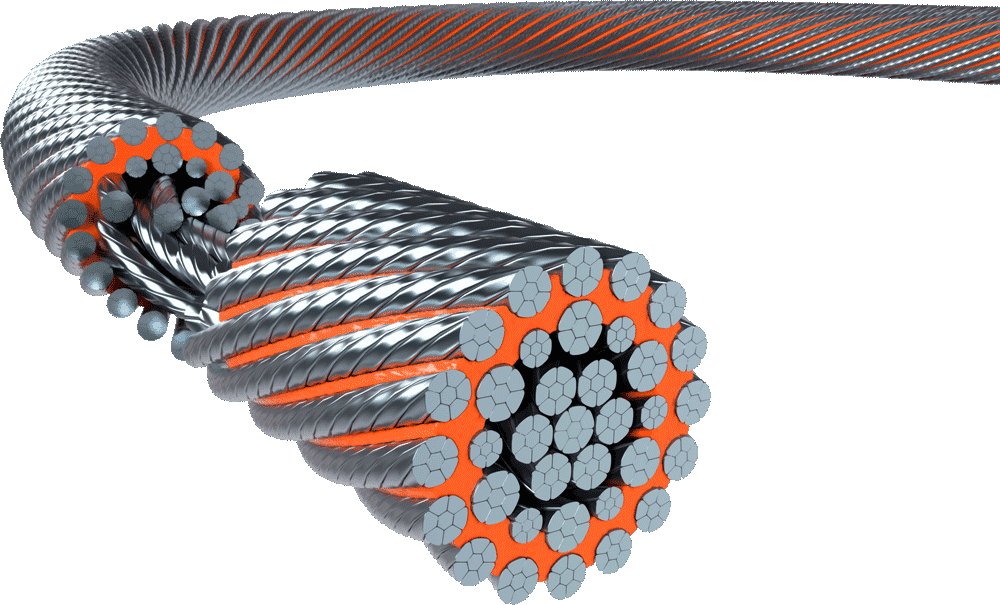

How Can Customization Improve Your Luffing Rope Performance?

Standard ropes may not always fit your cranes or lifting conditions. Custom ropes increase safety, reduce wear, and improve efficiency.

We can customize ropes with your logo, specific length, diameter, coating, or plastic impregnation. Tailored solutions extend rope life and make inspection easier.

Customization Options

Length & Diameter

Fit precisely to your crane drum and pulley sizes. Avoid mismatched ropes that reduce performance.

Coating & Impregnation

Galvanized or plastic-impregnated ropes resist corrosion and reduce internal friction. Perfect for marine cranes.

Load Rating

We can adjust the number of strands or core type to increase breaking load and safety.

Logo & Identification

Custom logos make inspection and traceability easier. It’s especially helpful for rental fleets or multi-site operations.

| Customization Type | Benefit | Example Application |

|---|---|---|

| Length & Diameter | Fit precisely to machinery | Tower cranes, marine cranes |

| Coating/Impregnation | Prolong rope life | Outdoor or marine use |

| Load Rating | Handle required weight safely | Heavy-lift operations |

| Logo & ID | Easier inspection & tracking | Industrial or rental fleets |

Real-World Experiences With Luffing Ropes

In one Australian project, we supplied 8XK26WS-IWRC ropes for a high-rise crane. The client reported smoother lifts, reduced vibration, and longer rope life.

On another project in Vietnam, we recommended 8XK26WS-EPWIRC for port cranes. Despite exposure to saltwater and heavy usage, the ropes showed minimal wear after 12 months.

I also helped a mining company choose 6XK36WS-IWRC ropes for frequent heavy lifting. The ropes performed flawlessly under continuous use, saving both maintenance costs and downtime.

These examples show that choosing the right rope structure, certification, and customization can make a huge difference in project success.

Maintenance Tips for Luffing Ropes

Even the best ropes need proper maintenance.

Regular inspection, lubrication, and proper storage extend rope life. Avoid kinking, overloading, or sudden shocks. Certified ropes combined with good care maximize safety.

Rope Maintenance

- Visual Inspections: Check for broken wires, corrosion, or deformation.

- Lubrication: Use appropriate rope lubricants to reduce friction and wear.

- Storage: Keep ropes off the ground and away from moisture.

- Load Monitoring: Avoid exceeding working load limits.

| Maintenance Step | Action Needed | Frequency |

|---|---|---|

| Visual Inspection | Check wires, kinks, corrosion | Weekly |

| Lubrication | Apply rope lubricant | Monthly |

| Storage | Keep dry, off ground | Always |

| Load Monitoring | Do not exceed working load limit | Every lift |

Conclusion

High-quality, certified luffing ropes like 8XK26WS-IWRC, 6XK36WS-IWRC, EPWIRC, and 10-strand ropes ensure safety, durability, and smooth operation for cranes. Proper selection and maintenance make all the difference.