Struggling with crane rope failures can halt your project. Choosing the right crawler crane wire rope prevents accidents and saves time.

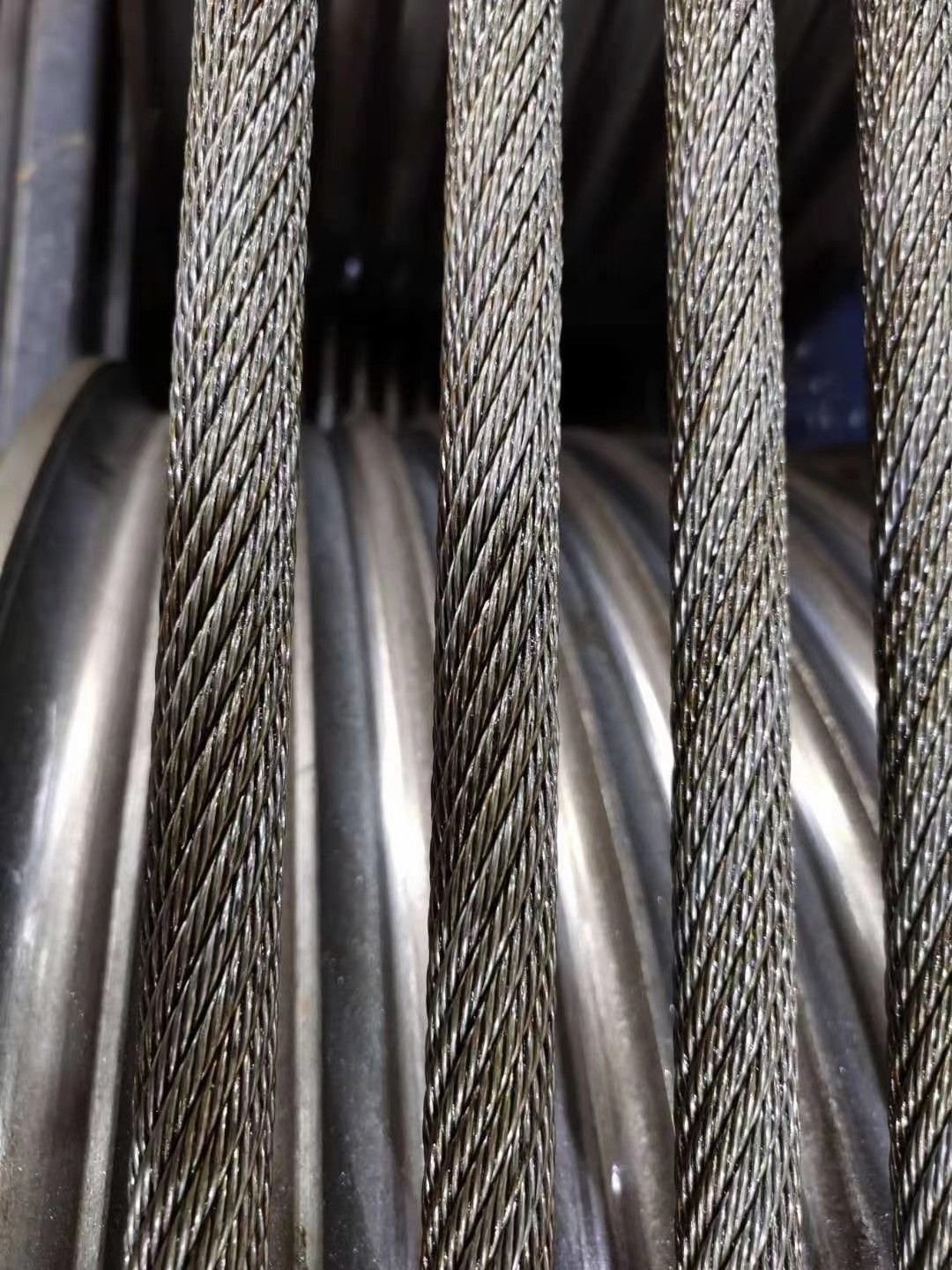

Crawler crane wire ropes are designed for heavy-duty lifting. They offer high tensile strength, excellent rotation resistance, and long service life, keeping your operations safe and efficient.

Let me show you how different rope constructions solve lifting challenges and why proper selection matters for every crane operator.

Why Should You Consider 18XK7-EPWSC for Your Hoist Operations?

This rope is ideal for main and auxiliary hoist operations. It is rotation resistant, fatigue-resistant, and has a robust construction that handles high breaking loads efficiently.

| Feature | Benefit |

|---|---|

| Rotation Resistant | Prevents rope spinning under load, increasing safety |

| Improved Bend Fatigue | Extends rope life during repeated lifting cycles |

| Robust Construction | Maintains shape under heavy loads |

| High Breaking Strength | Handles large lifting capacities safely |

| Smooth Exterior | Reduces wear on sheaves and drums |

Plastic impregnation in 18XK7-EPWSC spreads between strands and the core. This design reduces internal friction and wear, giving longer rope life. It works perfectly on cranes where both main and auxiliary hoists require reliability.

I remember a project where a customer switched to this rope. Before, frequent replacements slowed the work. After switching, downtime dropped and maintenance costs decreased. Seeing these results convinced me that the right rope choice changes everything on-site.

How Does 35WX7 Meet Port and Construction Crane Needs?

35WX7 offers excellent rotation resistance and flexible construction. It performs well on single-layer drum setups, making it a trusted choice for port and construction cranes.

| Feature | Advantage |

|---|---|

| Rotation Resistant | Prevents spinning for safe lifts |

| Flexible Construction | Easy reeving and smooth operation |

| Single-Layer Drum Use | Optimized for specific drum setups |

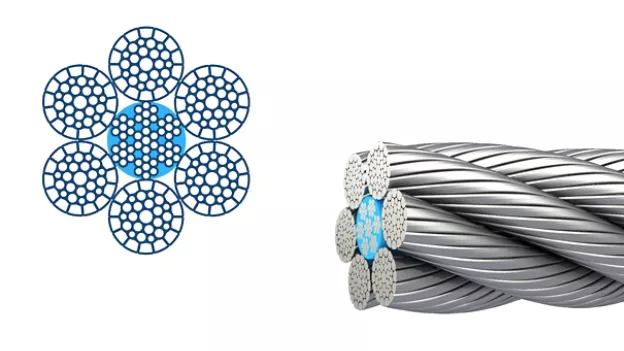

This rope is compacted and EN 12385-4 compliant. High tensile strength and abrasion resistance reduce sheave wear, while its multistrand design ensures reliability during high lifts.

I once advised a client installing a port crane. They initially used a generic rope. They faced alignment issues and higher rope fatigue. Switching to 35WX7 solved these problems. Operations became smoother, and crew safety improved.

Why Is 6X36WS-IWRC Recommended for Multi-Crane Applications?

6X36WS-IWRC improves bending fatigue performance and retains internal lubrication. It’s versatile for construction, port, industrial, offshore cranes, winches, and drilling rigs.

| Feature | Benefit |

|---|---|

| IWRC Core | Stronger rope support and longer life |

| Compaction | Reduced internal friction |

| Multiple Steel Grades | 1770, 1960, 2160 for varied lifting needs |

| Langs/Regular Lay | Flexible installation options |

| RH or LH | Meets specific machinery requirements |

This rope suits cranes that experience heavy and repetitive lifting. Its high-quality steel grades and compacted strands improve wear resistance and extend operational life.

I remember a mining client who needed ropes for both onshore and offshore operations. They wanted one rope type for all cranes. I recommended 6X36WS-IWRC, explaining how its IWRC core and compaction resist bending fatigue. After months, they reported fewer replacements and smoother lifting.

How Does 35WXK7-EPWSC Enhance Crane Performance?

35WXK7-EPWSC combines flexibility with rotation resistance. Suitable for single or multi-part reeving, it maintains high efficiency under continuous lifting operations.

| Feature | Advantage |

|---|---|

| Compacted PI Core | Protects strands and improves rope life |

| Steel Grades | 1960 or 2160, for heavy loads |

| Langs/Regular Lay | Versatile installation |

| Bright or Galvanized Finish | Corrosion resistance |

The engineered extruded plastic in the outer strands reduces wear and increases smoothness. High rotation resistance and flexibility make it perfect for industrial and offshore cranes.

I once tested this rope on an industrial crane. It reduced downtime caused by rope twisting. The crew noticed smoother lifting, and maintenance teams praised its wear resistance. This rope is a long-term investment for crane performance.

What Advantages Does 8X26WS-IWRC Provide?

8X26WS-IWRC improves bending fatigue performance and retains internal lubrication. It is suitable for construction, port, industrial, offshore cranes, winches, and drilling rigs.

| Feature | Benefit |

|---|---|

| IWRC Core | Retains lubrication and reduces wear |

| Compacted Strands | Enhances durability for industrial use |

| Multi-Crane Applications | Suitable for various crane types |

This rope reduces internal friction and supports smooth operation under heavy loads. It is ideal for demanding environments where long service life is critical.

In one offshore project, we used 8X26WS-IWRC on a drilling rig. It lasted significantly longer than standard ropes, reducing replacements and improving safety.

How Does 6XK36WS-EPIWRC Extend Rope Life?

6XK36WS-EPIWRC is a high-performance compacted rope with plastic-impregnated core. This further extends rope life and reduces friction on external strands.

| Feature | Benefit |

|---|---|

| Plastic Impregnation | Reduces friction and wear, extends rope life |

| Compacted Single Layer | Ensures stable and durable rope construction |

| Multi-Crane Use | Works for construction, industrial, and offshore cranes |

Plastic impregnation protects strands and increases durability. This rope is perfect for cranes where longevity and reliability are key.

In an offshore drilling setup, switching to 6XK36WS-EPIWRC reduced rope replacements and improved operational safety. The client reported smoother lifting and lower maintenance costs.

How Do I Choose the Right Wire Rope for My Crawler Crane?

Choosing depends on crane type, lifting load, reeving method, drum type, and environment. Consider rotation resistance, fatigue performance, and optional plastic impregnation for longer rope life.

| Factor | What to Consider |

|---|---|

| Crane Type | Construction, port, offshore, industrial |

| Load | Maximum lifting weight and safety margin |

| Reeving | Single-part or multi-part reeving setup |

| Drum Type | Single-layer or multi-layer drums |

| Rope Construction | Rotation resistance, compaction, PI core |

| Environmental Conditions | Corrosion, temperature, wear |

I often walk clients through these factors. For example, port cranes with single-layer drums need flexible low-rotation ropes like 35WX7. Offshore cranes facing saltwater require galvanized or PI ropes to resist corrosion. Proper selection prevents downtime and keeps operations smooth.

Installation Tips for Crawler Crane Wire Ropes

Proper installation is key to rope life. Always inspect drums and sheaves before mounting. Ensure the rope is aligned correctly with grooves to avoid uneven wear.

| Tip | Reason |

|---|---|

| Use correct drum alignment | Prevents rope deformation |

| Avoid sharp bends | Reduces fatigue failure |

| Lubricate if needed | Maintains internal strands |

I often supervise first-time installations. A simple misalignment can reduce rope life by months. Proper training and careful installation prevent costly mistakes.

Maintenance Practices to Extend Rope Life

Routine checks are essential. Inspect for broken wires, corrosion, and wear. Replace ropes at the first sign of damage. Clean and lubricate when necessary.

| Maintenance Task | Frequency |

|---|---|

| Visual inspection | Weekly |

| Lubrication | Monthly or after heavy use |

| Replacement check | Based on wear or break count |

In my experience, ropes that are maintained regularly last much longer. A client saved thousands in replacements after implementing a strict inspection routine.

Common Mistakes to Avoid

Many operators ignore rotation resistance or load limits. Overloading, poor lubrication, and improper storage reduce rope life dramatically.

| Mistake | Consequence |

|---|---|

| Overloading | Premature breakage |

| Poor alignment | Increased wear and fatigue |

| Neglecting inspection | Hidden damage causes failure |

| Using wrong rope type | Safety risks and downtime |

I always emphasize these points during training. Avoiding these mistakes ensures safe, efficient, and long-lasting crane operations.

Conclusion

Crawler crane wire ropes provide safety, efficiency, and long service life when selected, installed, and maintained properly.