I see many projects slow down because the wrong rope fails. This creates stress and cost.

Foundation equipment needs the right wire rope because each rope type handles specific loads, motions, and safety demands that affect durability, breaking force, and project stability.

I learned this early in my business when a client rushed an order and used a rope that did not match the job. The failure changed how I work forever.

Why does a hoist rope matter so much in foundation equipment?

I face this question often when clients compare rope models and prices.

A hoist rope matters because it carries the main lifting load. Ropes like 35WXK7, 35WXK7-EPWRC, and 15XK7 give strong rotation resistance, high strength, and better stability for heavy foundation equipment.

How different hoist ropes change performance

I use hoist ropes every week in production, so I know how each structure works. I test every batch with strict standards because heavy loads need stable lifting and safe rotation control.

35WXK7: High rotation resistance

This rope helps with main hoist movements. It stays stable under heavy vertical loads.

It works well in foundation rigs, cranes, and deep pile projects.

Key specs overview

| Feature | Description |

|---|---|

| Structure | 35WXK7 |

| Strength | High tensile |

| Benefit | Good anti-rotation |

| Use | Main hoist |

35WXK7-EPWRC: Extra plastic protection

I use this when clients face harsh mud, sand, or water conditions.

| Feature | Description |

|---|---|

| Coating | Plastic impregnated |

| Core | Steel core |

| Benefit | Longer fatigue life |

| Use | Heavy foundation hoist |

15XK7: Stable and strong

This rope carries heavy tools and protects against twist. I send this rope often to Southeast Asia because it works well with soil mixing rigs.

| Feature | Description |

|---|---|

| Structure | 15-strand |

| Benefit | Stable, balanced |

| Breaking load | Very high |

| Use | Main hoist in harsh jobs |

Why these ropes matter in real jobs

When I work with clients in large foundation projects, I see how soil layers change the load pattern. A rope with poor rotation control causes tool swing.

This slows the work. It also increases repair time.

That is why I push for these models. They match hard soil, deep piles, and long lifting hours.

Why is the auxiliary hoist rope different from the main hoist rope?

I notice many buyers mix these two ropes when they first contact me.

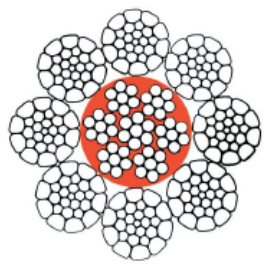

The auxiliary hoist rope handles lighter lifts and faster cycles. Models like 8XK26WS-IWRC give flexibility, good bending fatigue, and strong core support for daily foundation tool movements.

Why auxiliary ropes use different designs

Auxiliary ropes move more times per day. They bend more around sheaves. They face abrasion from repeated short-cycle lifting.

So I choose structures with more wires and compact strands.

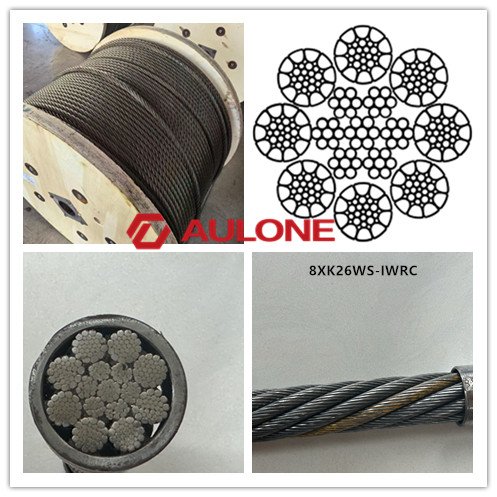

8XK26WS-IWRC: Flexible and strong

This rope is one of my most common exports. It works well in dynamic lifting tasks.

| Feature | Description |

|---|---|

| Structure | 8-strand compact |

| Core | IWRC |

| Benefit | Strong + flexible |

| Use | Auxiliary hoist |

8XK26WS-EPWRC (Plastic coated core)

Some clients ask for plastic protection when working near seawater or in soft clay that traps water.

| Feature | Description |

|---|---|

| Protection | EPWRC |

| Benefit | Better fatigue life |

| Use | Long-cycle lifting |

Real-world use

I worked with a client who used the wrong rope for auxiliary movement. The rope wore out after weeks.

When they switched to 8XK26WS-IWRC, the rope life doubled. That moment made me more firm about rope selection.

How does foundation equipment change my rope choice?

Each machine demands a rope that matches its duty.

Foundation equipment changes rope choice because load type, drilling depth, tool weight, and soil condition all affect which structure gives the safest, longest service life.

Looking at job conditions

I check several factors before I advise clients:

1. Soil hardness

Hard soil creates shock loads.

Soft soil creates suction loads.

Each condition changes tension.

| Soil Type | Rope Impact |

|---|---|

| Hard rock | Higher shock load |

| Mixed soil | Vibration + twist |

| Soft clay | Drag and suction |

2. Tool weight

Heavier tools need stronger anti-rotation.

| Tool | Rope Need |

|---|---|

| CFA tools | High strength |

| Drill buckets | Anti-rotation |

| Augers | Stable torque |

3. Drilling depth

Deep piles increase total load.

This requires higher breaking load and better rotation control.

What I see in factories

My factory uses four production lines.

Each line focuses on a group of rope structures.

This lets me test each lot faster and keep quality stable.

Buyers who need certificates like BV, CE, RMRS, DNV, or ABS usually choose these foundation ropes.

Why do certifications matter in foundation work?

Many buyers ask this when they compare prices from different suppliers.

Certifications matter because they prove the rope meets global safety rules. They also reduce project risk and help buyers pass audits for large foundation or crane contracts.

What each certificate covers

I help buyers prepare documents for tenders.

Large construction groups need inspection proof.

I provide third-party testing when required.

| Certificate | Meaning |

|---|---|

| BV | Marine + industrial approval |

| CE | European compliance |

| RMRS | Russia marine class |

| DNV | Offshore compliance |

| ABS | Heavy lifting, marine |

Why clients rely on certified ropes

One project used uncertified ropes from a local shop. After three months, the rope failed.

The cost of repair was higher than the price of the certified rope.

That case pushed many buyers to use certified products only.

Conclusion

Right ropes make foundation work safer, stronger, and more stable.