Duty cycle crawler crane scraper ropes offer high breaking strength, strong resistance to external impacts, rotation-resistant stability, long fatigue life, and reliable performance under continuous heavy digging cycles.

I learned these lessons after watching a scraper stop in the middle of a riverbed project. That moment pushed me to study rope structures much deeper.

Why do hoist ropes matter so much in heavy scraper duty?

Hoist ropes lift the scraper bucket vertically. When they fail, the entire operation stops.

Hoist ropes matter because they lift the full vertical load, resist crushing on multi-layer drums, remain stable under impact, and support fast, repeated cycles without losing strength or geometry.

What exactly does a hoist rope do?

A scraper bucket moves up and down all day. The hoist rope holds the bucket weight, the soil load, and the shock when the bucket hits the ground.

This means:

- The load is not constant

- The impact is high

- The cycle time is fast

- The wear is heavy

Hoist ropes need both toughness and stability. A simple rope cannot handle this work.

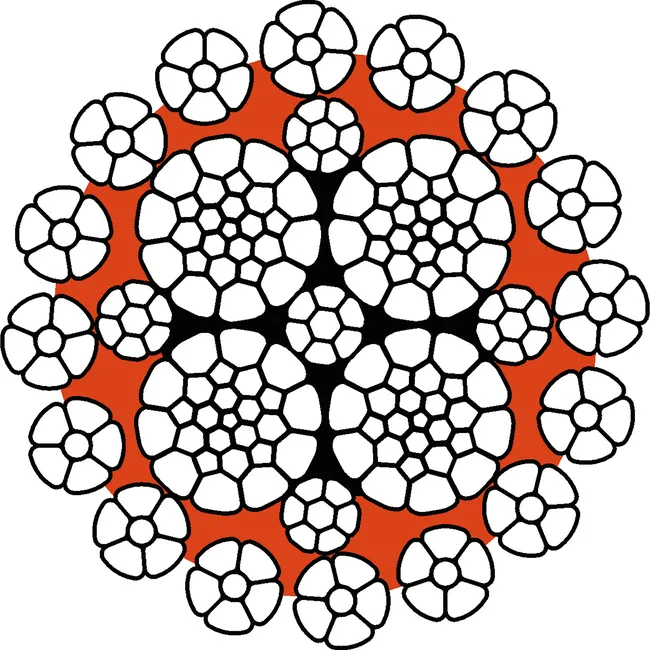

Cross-section of steel wire rope: Why the structure matters

A high-performance hoist rope has multiple layers of wires and strands. Each layer plays a different role.

Basic cross-section functions

| Component | Function |

|---|---|

| Outer wires | Handle abrasion from soil and sheaves |

| Outer strands | Carry main tension load |

| Inner strands | Distribute stress evenly |

| Core (IWRC / EPIWRC) | Maintain rope shape and resist crushing |

Scraper machines use deep drum spooling, so the rope must stay round.

Why I choose 16xK6-EPIWRC(K) for hoist ropes

This construction gives a good balance between strength, flexibility, and stability.

| Feature | Benefit |

|---|---|

| 16 strands | More wires → better flexibility |

| K-compacted strands | Higher metallic cross-section → better strength |

| 6-wire strand design | Resistant to external pressure and abrasion |

| EPIWRC (plastic-coated core) | Protects inner strands from water, dust, corrosion |

| Rotation Resistant | Prevents bucket spinning |

Scraper buckets drop fast. They hit the ground. They shake the whole rope system. A rotation-resistant structure reduces twist and improves safety.

High resistance to external influences

Scraper job sites are not gentle places. The rope must survive:

- Soil friction

- Sharp stones

- Mud and water

- Abrasion from sheaves

- Dynamic side pressures

The plastic layer inside the rope works like a shield. It keeps the core clean and stable.

High breaking strength

I always choose high-tensile wires because they reduce wire breaks and extend rope life.

The high breaking load gives a safety margin for unexpected soil density changes.

High absorption capacity for impact loads

The bucket hits the soil hard.

The rope absorbs shock every cycle.

A good hoist rope must prevent internal wire movement.

Less movement means less fatigue and longer service time.

What makes boom hoist ropes different from scraper hoist ropes?

Boom hoist ropes do not move fast, but they hold the boom angle all day.

Boom hoist ropes use stable IWRC or EPIWRC cores, low-rotation strand designs, and strong wire counts to keep the boom fixed, resist sideways forces, and ensure safe operation of heavy crawler cranes.

The role of the boom hoist rope

The boom hoist rope does not experience the same shock as the scraper rope.

But the weight is heavy, and the stability requirement is strict.

If the boom shifts:

- The digging angle changes

- The bucket trajectory changes

- The machine becomes unsafe

This is why boom hoist ropes must stay stable under static and semi-static loads.

Lay direction: Lang’s lay or Ordinary lay?

I use both depending on the job:

| Lay Type | When I use it | Benefit |

|---|---|---|

| Lang’s lay | When I need abrasion resistance | Outer wires run longer → better wear |

| Ordinary lay | When stability is priority | Less rotation, more balanced |

Hand direction

- Right-handed

- Left-handed

The choice depends on the drum winding direction of the crane.

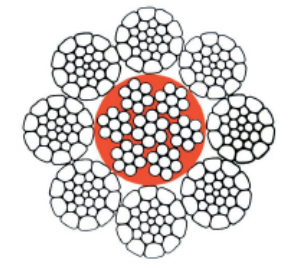

Special core structure for boom hoist ropes

The core is the heart of the rope. Without a strong core, the rope loses shape under tension.

We use engineered cores for stable geometry.

Size ranges and specifications

| Diameter | Construction | RCN | Number of wires | Why it matters |

|---|---|---|---|---|

| 10–42 mm | 8xK26WS-EPIWRC(K) | 09 | 208 | Flexible, stable, good for medium booms |

| 44–50 mm | 8xK31WS-EPIWRC(K) | 11 | 248 | High strength for large crawler cranes |

The WS (Warrington-Seale) structure has a mix of wire diameters.

This improves wear resistance and surface contact on the sheave.

How do pulling ropes support scraper operations?

The pulling rope drags the scraper bucket forward. It works under high horizontal force.

Pulling ropes deliver stable horizontal traction, resist rotation, handle abrasion, and survive constant stop-and-pull cycles during scraper work. Their structure keeps them stable under shifting loads.

The hidden stress in pulling ropes

Unlike hoist ropes, pulling ropes work horizontally.

This creates different stress patterns:

- Side friction

- Soil pressure

- Direction changes from uneven digging

- Load spikes when the bucket hits compact soil

These forces can flatten a weak rope. That is why the core structure must stay firm.

Lay direction options

Pulling ropes may be:

- Lang’s lay

- Ordinary lay

- Right-handed

- Left-handed

Scraper cycles involve constant changes in angle.

Lang’s lay offers more surface wear resistance.

Ordinary lay gives better geometry stability.

Special core structure for pulling ropes

A strong core reduces rope deformation.

A round rope spools better and runs longer.

Size ranges used for pulling ropes

| Diameter | Construction | RCN | Number of wires | Key feature |

|---|---|---|---|---|

| 10–42 mm | 8xK26WS-EPIWRC(K) | 09 | 208 | Tough surface, stable under tension |

| 44–50 mm | 8xK31WS-EPIWRC(K) | 11 | 248 | Suitable for large, high-power duty cycle cranes |

The K-compacted strands increase metal area and breaking strength.

How do I choose the right wire rope for duty cycle crawler cranes?

My selection method became more systematic after many failures on job sites.

I choose ropes based on load, drum size, soil conditions, cycle frequency, rotation requirements, and environmental exposure. The right rope must match the job, not just the crane.

My complete selection framework

I follow a structured approach now.

It makes the decision clear for each rope type.

Step 1 — Identify the application

| Rope Type | Correct Construction |

|---|---|

| Hoist rope | 16xK6-EPIWRC(K) |

| Boom hoist rope | 8xK26WS or 8xK31WS |

| Pulling rope | 8xK26WS or 8xK31WS |

Each rope sees different loads and directions.

One type cannot replace another.

Step 2 — Check the load and safety factor

I compare:

- Working Load

- Breaking Load

- Sheave diameter

- Drum diameter

A correct safety factor prevents sudden failures.

Step 3 — Consider the drum and sheave size

Smaller drums need more flexible ropes.

Large drums allow larger metallic cross-sections and higher wire counts.

Step 4 — Evaluate the environment

I look for moisture, chemicals, soil abrasiveness, and temperature.

In wet or salty areas, I always recommend galvanized + plastic impregnated cores.

Step 5 — Check rotation resistance requirements

Some operations need:

- Full rotation resistance

- Partial resistance

- No resistance

Hoist ropes need full rotation control.

Pulling ropes may need partial rotation resistance.

Boom hoist ropes usually need low rotation.

Step 6 — Confirm certificate requirements

Many clients in mining, marine, and oil field projects request:

- BV

- CE

- RMRS

- DNV

- ABS

I provide these when needed.

Conclusion

Scraper ropes must combine strength, stability, and endurance for harsh duty cycles.