Overhead cranes stop projects when the wire rope fails. Delays cost money. Safety risks rise fast. Many buyers feel unsure because too many rope types look similar at first glance.

An overhead crane wire rope must match the crane type, lifting duty, and safety rules. I always focus on structure, breaking load, rotation resistance, and certification before I confirm any model for overhead crane use.

I have worked with overhead cranes in many markets. Each project taught me the same lesson. The right rope solves problems early. The wrong rope creates hidden risks later. That is why this topic matters.

How does an overhead crane system affect wire rope selection?

Overhead cranes look simple, but the system design changes rope behavior a lot.

An overhead crane needs wire ropes with stable structure, low elongation, and high breaking load. Hoist layout, drum design, and lifting height decide whether rotation resistance and plastic impregnation are required.

Overhead crane working conditions

Overhead cranes often work indoors. Loads move vertically and horizontally. Starts and stops are frequent. The rope must stay stable on the drum.

| Factor | Impact on wire rope |

|---|---|

| Lifting frequency | Increases fatigue stress |

| Drum layers | Raises crushing risk |

| Lifting height | Affects elongation control |

| Load stability | Requires rotation resistance |

Why overhead cranes need stricter rope control

I always explain this clearly. Overhead cranes operate above people and equipment. Any rope issue becomes a safety issue. That is why I insist on EN12385-4 compliance and third-party inspection when needed.

Overhead crane duty classes and rope life

Different duty classes change rope life fast. Light duty cranes allow more flexible designs. Heavy duty cranes need compact strands and higher steel fill factor. I never mix these two concepts.

What is the role of the hoist rope in an overhead crane?

The hoist rope does the main lifting work. Its role is critical.

A hoist rope for an overhead crane must provide high breaking load, low elongation, and stable drum behavior. It carries most fatigue cycles and defines the crane’s safety margin.

Hoist rope load behavior

The hoist rope sees direct vertical force. Load changes happen suddenly. I always calculate safety factor with real working load, not rated load.

| Item | Requirement |

| Breaking load | High margin above SWL |

| Elongation | Controlled and predictable |

| Fatigue resistance | High bending endurance |

Common hoist rope mistakes

Some buyers focus only on price. Others copy old specifications. I have seen both fail. A hoist rope must match the drum groove and sheave diameter exactly.

Why compact strand ropes work better

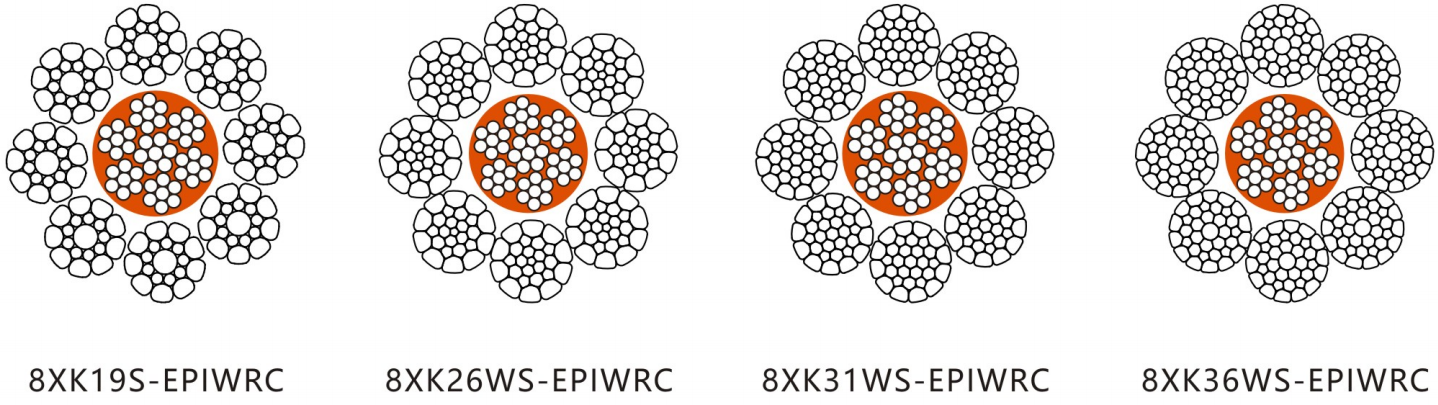

Compact strand designs like 8XK structures give higher metal area. This improves breaking load without increasing diameter. For overhead cranes, this advantage is real.

When should an auxiliary hoist rope be used?

Auxiliary hoists often look secondary, but they are not.

An auxiliary hoist rope supports lighter loads but higher positioning accuracy. It still needs good fatigue resistance and smooth operation to avoid shock loading.

Auxiliary hoist working pattern

Auxiliary hoists handle frequent short lifts. This creates more bending cycles. I usually recommend flexible but compact constructions.

| Feature | Focus |

| Flexibility | Improves bending life |

| Surface finish | Reduces drum wear |

| Consistent diameter | Ensures smooth lifting |

Cost versus performance balance

I do not overspec auxiliary hoist ropes. But I never under-spec them. Balance keeps cost controlled and performance stable.

Why is 8XK26WS-IWRC popular for overhead cranes?

This structure appears often in overhead crane projects.

8XK26WS-IWRC offers high breaking load, good fatigue resistance, and stable structure. It suits overhead crane hoist ropes where compact design and strength are both required.

Structure analysis of 8XK26WS-IWRC

This rope uses eight compact strands. Each strand contains Warrington-Seale wires. The IWRC improves core support.

| Element | Benefit |

| 8 strands | Better load distribution |

| WS pattern | High metal area |

| IWRC | Improved crushing resistance |

Real project advantages

In several export projects, this rope reduced diameter limits while keeping the same lifting capacity. This helped clients upgrade cranes without changing hardware.

What extra benefits does 8XK26WS-EPIWRC provide?

Some overhead cranes need more than strength.

8XK26WS-EPIWRC adds plastic impregnation inside the core. This improves internal lubrication, reduces friction, and extends service life in demanding overhead crane applications.

Plastic impregnation explained

Plastic fills the gaps between wires. This keeps lubricant inside. Water and dust stay out. Fatigue life improves.

| Condition | Improvement |

| Internal wear | Reduced |

| Lubricant loss | Slower |

| Service life | Longer |

When I recommend EPIWRC

I suggest this version for high-cycle cranes or dusty workshops. The higher initial cost pays back through longer replacement intervals.

How does 35WXK7 perform in overhead crane hoisting?

Rotation control becomes critical in some cranes.

35WXK7 is a rotation-resistant wire rope. It limits load spin and improves lifting precision. It suits overhead cranes with single-fall or sensitive lifting conditions.

Rotation resistance principle

This rope balances torque between layers. When the load lifts, rotation forces cancel each other.

| Feature | Effect |

| Multi-layer design | Torque balance |

| High wire count | Smooth operation |

Limits of rotation-resistant ropes

I always explain this clearly. These ropes need careful installation. Wrong reeving reduces their advantage.

What is the advantage of 35WXK7-EPWSC?

Some projects demand maximum control and protection.

35WXK7-EPWSC combines rotation resistance with plastic coating. It offers better wear protection and stable torque control for advanced overhead crane systems.

Plastic coating role

The coating protects outer wires. It reduces abrasion and corrosion risk. Drum life also improves.

| Benefit | Result |

| Surface protection | Less wear |

| Corrosion resistance | Improved |

Typical applications

I see this rope used in high-value workshops and automated crane lines. Precision matters more than cost in these cases.

Conclusion

Choosing the right overhead crane wire rope improves safety, reduces downtime, and protects long-term investment.