I’ve seen many cranes fail due to poor wire ropes. It’s risky and costly. Choosing the right rope is crucial for smooth and safe operations.

Gantry STS crane wire ropes ensure high tensile strength, durability, and compliance with international standards. They protect your investment and guarantee safe lifting every time.

Let me share what I’ve learned after years of producing crane wire ropes. Knowing the differences can save money and prevent accidents.

What Makes Hoist Ropes Critical for Gantry STS Cranes?

Hoist ropes lift heavy loads every day. Choosing the right type is more than just size and length.

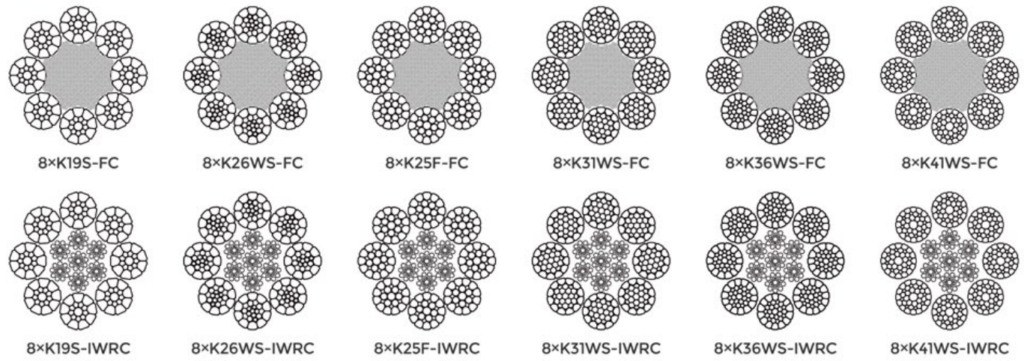

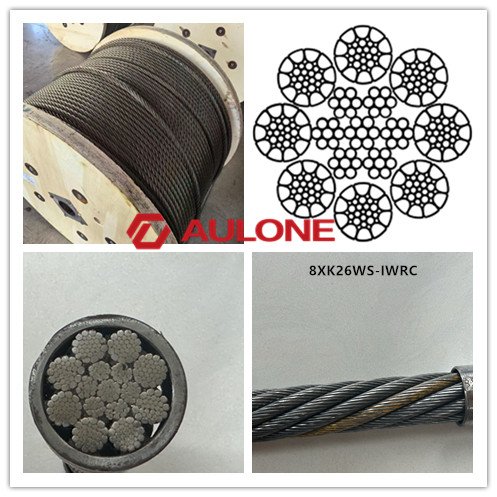

Hoist ropes like 8XK26WS-IWRC & 8XK36WS-IWRC, 8XK26WS-EPIWRC, and 10XK26WS-IWRC offer strength, flexibility, and resistance to wear, making them ideal for lifting operations.

Comparing Hoist Rope Options

I always recommend reviewing rope structure before purchase.

| Rope Type | Structure | Coating | Key Benefit |

|---|---|---|---|

| 8XK26WS-IWRC | 8 strands × 26 wires | Galvanized | High breaking load |

| 8XK26WS-EPIWRC | 8 strands × 26 wires | Plastic impregnated | Extra abrasion resistance |

| 10XK26WS-IWRC | 10 strands × 26 wires | Galvanized | Superior flexibility under load |

Hoist ropes carry the main load. Plastic impregnated ropes reduce fatigue. More strands improve smooth bending around drums. These details impact crane efficiency and rope lifespan.

Why Trolley Ropes Are Just as Important?

Trolley ropes move loads horizontally. Many overlook their role in crane performance.

Trolley ropes of 8XK26WS-IWRC, 8XK26WS-EPIWRC, and 10XK26WS-IWRC provide stable movement, prevent slippage, and ensure smooth operation. Proper selection avoids accidents and downtime.

Trolley Rope Selection

| Rope Type | Wire Core | Coating | Load Capacity |

|---|---|---|---|

| 8XK26 & 8XK36WS | IWRC | Galvanized | High tensile strength |

| 8XK26WS-EPIWRC | IWRC | Plastic impregnated | Anti-corrosion |

| 10XK26WS-IWRC | IWRC | Galvanized | Enhanced flexibility |

Trolley ropes work under constant friction with sheaves. Plastic impregnation reduces wear. More strands reduce vibration and keep the trolley movement smooth. Choosing correctly prevents rope stretch and drum damage.

How to Choose Luffing Ropes for Gantry STS Cranes?

Luffing ropes handle boom angle adjustments. Their strength affects precision and safety.

Luffing ropes 8XK26WS-IWRC & 8XK36WS-IWRC, 8XK26WS-EPIWRC, and 10XK26WS-IWRC balance flexibility and load capacity, ensuring controlled boom movements and minimal rope wear.

Luffing Rope Performance

| Rope Type | Strands × Wires | Coating | Strength |

|---|---|---|---|

| 8XK26WS-IWRC | 8×26 | Galvanized | High tensile |

| 8XK26WS-EPIWRC | 8×26 | Plastic impregnated | Abrasion resistant |

| 10XK26WS-IWRC | 10×26 | Galvanized | Flexible bending |

Luffing ropes face frequent angle changes. Galvanized wires resist corrosion. Plastic impregnation reduces internal friction. More strands improve bending fatigue life. The right rope reduces maintenance and prevents unexpected failure.

What Certification and Custom Options Should You Consider?

Certifications matter for safety and compliance. Custom options ensure your crane runs perfectly.

Our gantry crane ropes comply with EN12385-4, and can carry BV, CE, RMRS, DNV, and ABS certificates. We also offer logo customization and special coatings to match your operation needs.

Certificates and Customization

| Feature | Benefit | Applicable Ropes |

|---|---|---|

| EN12385-4 Compliance | Guaranteed quality | All |

| BV, CE, RMRS, DNV, ABS | International recognition | Hoist, Trolley, Luffing |

| Custom Logo | Branding and traceability | All |

| Galvanized or Plastic Impregnated | Corrosion and wear resistance | All |

Certifications protect operators and reduce liability. Custom logos help track your ropes in large fleets. Plastic coatings extend rope life in harsh weather. Choosing certified ropes ensures operational safety.

How Does Rope Construction Impact Crane Lifespan?

Rope construction defines its strength, flexibility, and wear resistance. Wrong choice shortens crane life.

Ropes like 8XK26WS-IWRC and 10XK26WS-IWRC offer high breaking load, fatigue resistance, and smooth drum operation. Correct construction reduces replacements and maintenance costs.

Understanding Rope Construction

| Rope Type | Core | Strand Layout | Ideal Use |

|---|---|---|---|

| 8XK26WS-IWRC | Independent Wire Rope Core | 8×26 | Hoist/Trolley/Luffing |

| 8XK26WS-EPIWRC | IWRC + Plastic Impregnated | 8×26 | Abrasion sensitive |

| 10XK26WS-IWRC | IWRC | 10×26 | Heavy load & bending |

More strands and independent wire rope cores give ropes higher flexibility and better fatigue life. Plastic impregnation reduces internal friction. These choices impact safety and cost.

Conclusion

Choosing the right gantry STS crane wire rope ensures safety, efficiency, and long-term cost savings.