Surface Mining Wire Rope

Underground Mining Wire Rope

Surface mining often requires heavy-duty equipment and machinery, including wire ropes, which are crucial for various operations. Wire ropes used in surface mining are specifically designed to withstand harsh environmental conditions, heavy loads, and constant abrasion. These ropes play a critical role in tasks such as hauling, lifting, and transporting materials.

Today’s miners work all over the world in some of the harshest conditions imaginable and face challenges that are getting tougher all the time. Aulone’s complete line of shovel and dragline ropes offer safe, proven technology that will outlast and outperform any rope on the market in terms of life and cost per ton in severe applications.

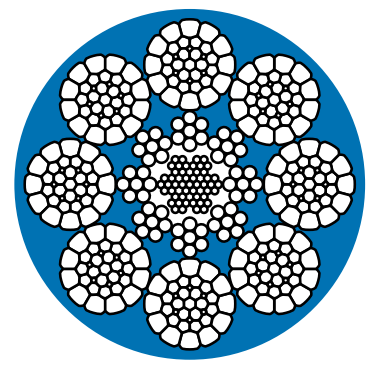

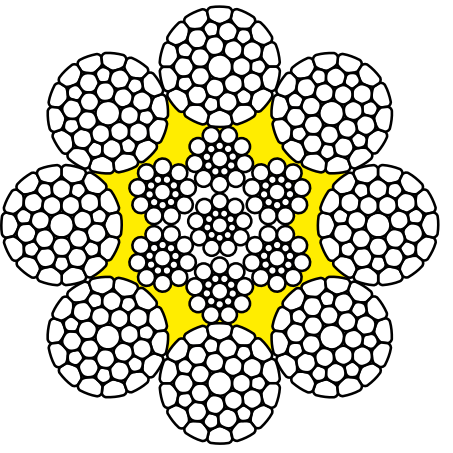

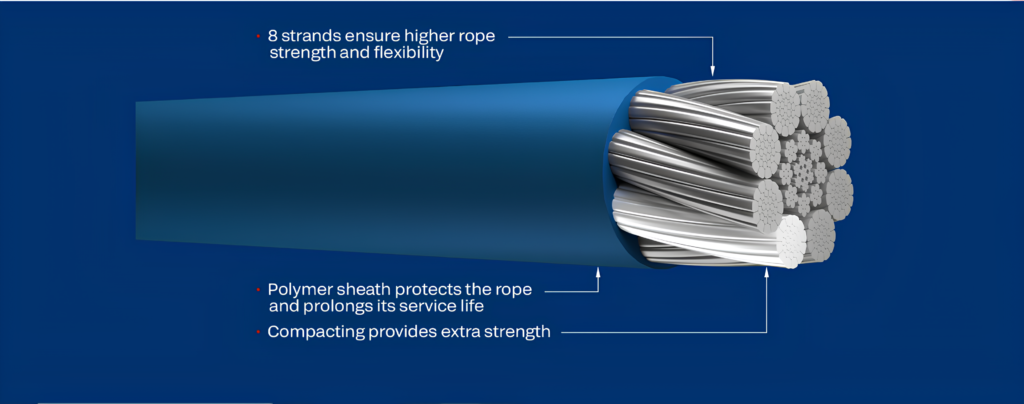

Polymer-coated wire ropes

For maximum surface protection of steel ropes, we have designed wire ropes with a polymer coating over the outer strands.

We use an ultra-strong polymer for the coating that sticks to the rope surface and doesn’t wear off during operation.

Because of their design, Aulone wire ropes last longer than standard ropes, which means fewer rope changes, less maintenance, and lower equipment ownership costs.

Shovels

Draglines

Tailored Surface Mining Wire Ropes to Suit Your Needs!

Surface mining wire ropes are critical components in heavy-duty applications, requiring durability, strength, and reliability. Whether it’s for hauling, lifting, or dragging, having a wire rope tailored to your specific needs can significantly enhance operational efficiency and safety.

Available Sizes: Ranging from 12mm up to 90mm.

Tensile Strength: 1570, 1770,1870, 1960, 2160, and 2260mpa.

Specifications on Offer: EN12385-4, GB 8918, YB/T5359 and specific customer requirements.

Surface Treatments: Options including hot galvanized A, AB,B, Zn95Al5, ungalvanized, plastic coated, and stainless steel.

Special technology: Including multi-strand ropes, plastic impregnated, plastic coated, compacted, galvanized.

Structure:8XK36WS-IWRC, 8XK36WS-EPIWRC, EP8XK36WS-IWRC,6XK36WS-IWRC, 6XK36WS-EPIWRC,EP6XK36WS-IWRC ,6xk36WS-FC etc.

Lay types: RHLL, RHRL, LHLL, LHOL

Termination: could be customized.

Overall, tailored underground mining wire ropes offer the advantage of optimized performance, longevity, and safety, contributing to the efficiency and success of mining operations while minimizing downtime and maintenance costs.

Beyond Simply Supplying Underground Mining wire rope

Beyond simply supplying surface mining wire rope, Aulone can add value and support their customers:

Customization Services:

In addition to supplying standard wire rope products, companies can offer customization services tailored to the specific needs of their clients. This might include engineering consultation to design wire ropes optimized for particular applications or environments

Training and Education

Providing training and educational resources for clients and their personnel can enhance safety and efficiency in surface mining operations. This could involve on-site training sessions, workshops, or online resources covering topics such as proper wire rope handling, maintenance, and inspection.

Technical Support:

Offering technical support services can help clients troubleshoot issues, optimize equipment performance, and address any challenges they encounter with wire ropes or related equipment. This might involve field support from experienced technicians or remote assistance via phone or video conferencing.

Lifecycle Management

Assisting clients in managing the entire lifecycle of their wire ropes can maximize their investment and ensure ongoing performance. This includes services such as routine inspections, condition monitoring, and proactive maintenance to detect and address issues before they escalate.

Supply Chain Solutions

Beyond wire ropes themselves, companies can provide comprehensive supply chain solutions to streamline procurement and logistics for their clients. This might involve inventory management, just-in-time delivery, or integration with clients’ procurement systems for seamless ordering and replenishment.

Research and Development

Investing in research and development can lead to the development of innovative wire rope technologies that offer enhanced performance, durability, and efficiency. Collaborating with clients and industry partners can ensure that new products meet the evolving needs of the surface mining sector.

Want to buy wire rope & sling?

We’re happy to assist you in finding the ideal rope for your application

86-15573139663

86-15363044363