Multi strand non-rotating wire ropes

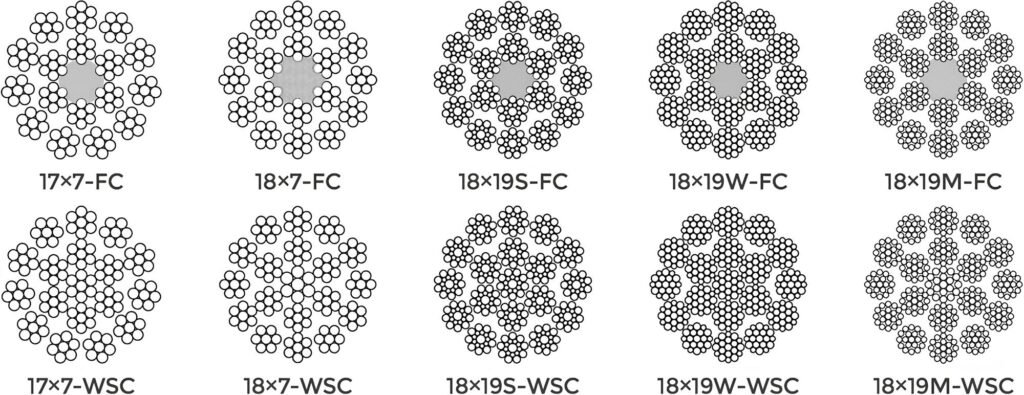

Construction

EN 12385-4 construction 18х7

18х7 (1+6) + 1 fiber core

18х7 (1+6) + 1х7 (1+6)

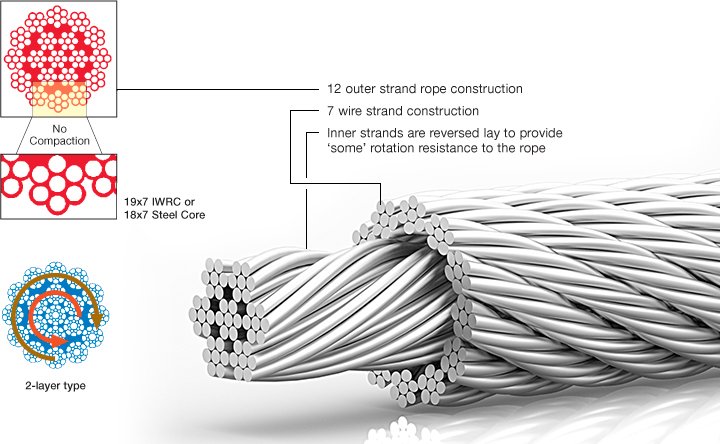

19×7 means the wire rope consists of 19 strands, and each strand is made up of 7 individual wires. This type of construction provides a good balance of flexibility and strength, making it suitable for various industrial applications.

Application:

Tower cranes

Crawler cranes

Pile-driver

Material:

Bright Wire refers to steel wire that is in its natural, untreated form, meaning it has no coating, such as galvanization or any corrosion-resistant layers. This gives the wire a shiny finish, but it also makes it more prone to oxidation and corrosion over time.

For environments where corrosion resistance is critical, galvanized or coated steel wire ropes may be more appropriate.

Features and Benefits:

High flexibility

High strength

Reduced friction between outer wires in strands

and pulley groove surface

Rotation resistance

Technical Parameters

| Diameter (mm) | Approx. weight (kg/100m) | Tensile strength (MPa) | ||||||||

| 1570 | 1770 | 1960 | 2160 | |||||||

| Minimum breaking load (kN) | ||||||||||

| (mm) | FC | WC | FC | WC | FC | WC | FC | WC | FC | WC |

| 6 | 14.0 | 15.5 | 17.5 | 18.5 | 19.8 | 20.9 | 21.9 | 23.1 | 24.1 | 25.5 |

| 7 | 19.1 | 21.1 | 23.8 | 25.2 | 26.9 | 28.4 | 29.8 | 31.5 | 32.8 | 34.7 |

| 8 | 25.0 | 27.5 | 31.1 | 33.0 | 35.1 | 37.2 | 38.9 | 41.1 | 42.9 | 45.3 |

| 9 | 31.6 | 34.8 | 39.4 | 41.7 | 44.4 | 47.0 | 49.2 | 52.1 | 54.2 | 57.4 |

| 10 | 39.0 | 43.0 | 48.7 | 51.5 | 54.9 | 58.1 | 60.8 | 64.3 | 67.0 | 70.8 |

| 11 | 47.2 | 52.0 | 58.9 | 62.3 | 66.4 | 70.2 | 73.5 | 77.8 | 81.0 | 85.7 |

| 12 | 56.2 | 61.9 | 70.1 | 74.2 | 79.0 | 83.6 | 87.5 | 92.6 | 96.4 | 102 |

| 13 | 65.9 | 72.7 | 82.3 | 87.0 | 92.7 | 98.1 | 103 | 109 | 113 | 120 |

| 14 | 76.4 | 84.3 | 95.4 | 101 | 108 | 114 | 119 | 126 | 131 | 139 |

| 16 | 99.8 | 110 | 125 | 132 | 140 | 149 | 156 | 165 | 171 | 181 |

| 18 | 126 | 139 | 158 | 167 | 178 | 188 | 197 | 208 | 217 | 230 |

| 20 | 156 | 172 | 195 | 206 | 219 | 232 | 243 | 257 | 268 | 283 |

| 22 | 189 | 208 | 236 | 249 | 266 | 281 | 294 | 311 | 324 | 343 |

| 24 | 225 | 248 | 280 | 297 | 316 | 334 | 350 | 370 | 386 | 408 |

| 26 | 264 | 291 | 329 | 348 | 371 | 392 | 411 | 435 | 453 | 479 |

| 28 | 306 | 337 | 382 | 404 | 430 | 455 | 476 | 504 | 525 | 555 |

| 30 | 351 | 387 | 438 | 463 | 494 | 523 | 547 | 579 | 603 | 638 |

| 32 | 399 | 440 | 498 | 527 | 562 | 594 | 622 | 658 | 686 | 725 |

| 36 | 505 | 557 | 631 | 667 | 711 | 752 | 787 | 833 | 868 | 918 |

| 40 | 624 | 688 | 779 | 824 | 878 | 929 | 972 | 1030 | 1070 | 1130 |

| 44 | 755 | 832 | 942 | 997 | 1060 | 1120 | 1180 | 1240 | 1300 | 1370 |

| 48 | 899 | 991 | 1120 | 1190 | 1260 | 1340 | 1400 | 1480 | 1540 | 1630 |

| 52 | 1050 | 1160 | 1320 | 1390 | 1480 | 1570 | 1640 | 1740 | 1810 | 1920 |

| 56 | 1220 | 1350 | 1530 | 1610 | 1720 | 1820 | 1910 | 2020 | 2100 | 2220 |

| 60 | 1400 | 1550 | 1750 | 1850 | 1980 | 2090 | 2190 | 2310 | 2410 | 2550 |

Series

Considerations:

Corrosion Resistance: Bright wire is not corrosion-resistant, so it is best suited for environments where it will not be exposed to moisture or chemicals. If the rope will be used in harsh environments (e.g., marine or wet conditions), galvanized or coated wire rope would be a better choice.

Maintenance: Regular inspections for rust, wear, or damage are important to ensure the rope remains safe to use. Any signs of corrosion or severe wear should be addressed immediately by replacing the affected sections.

In summary, 19×7 bright wire rope is a flexible and durable option for lifting, hoisting, and towing applications in environments where corrosion is not a significant concern. However, it requires careful maintenance to ensure a long service life, especially in non-protected conditions.