Are you looking for strong lifting tools? Do you need reliable ways to move heavy loads? Wire rope slings are crucial for safe lifting operations.

Wire rope slings lift and move heavy objects. They are used in many industries. They offer strength and durability for various tasks.

I once had a client, Andri, from Australia. He needed highly durable lifting solutions for his projects. He knew the importance of quality. He understood that good slings make work safer and more efficient.

Why are wire rope slings vital for heavy lifting?

Wire rope slings are critical for many lifting jobs. They ensure safety and efficiency. They are designed for tough tasks.

Wire rope slings provide high tensile strength. They have a high breaking load. This makes them ideal for demanding lifting work.

When we talk about heavy lifting, strength is key. Wire rope slings are made from high-quality steel wire. These wires are twisted into strands. Then these strands are twisted into ropes. This structure gives them incredible strength. They can lift objects that weigh many tons. This is why industries rely on them.

What makes wire rope slings so strong?

- Material Quality: They are made from high-grade carbon steel. This steel is known for its strength.

- Construction Method: The ropes are laid in a specific way. This spreads the load evenly. It prevents early failures.

- Breaking Load: Each sling has a tested breaking load. This number shows how much weight it can handle before failing.

How do wire rope slings ensure safety?

Safety is the top priority in lifting. Wire rope slings offer several safety features.

- Compliance: Our slings meet standards like EN12385-4. These standards ensure quality and safety.

- Certifications: We can provide BV, CE, RMRS, DNV, and时不时的 ABS certificates. These prove that our slings are tested and approved.

- Inspection: Slings need regular checks. This helps identify wear or damage early. Regular checks prevent accidents.

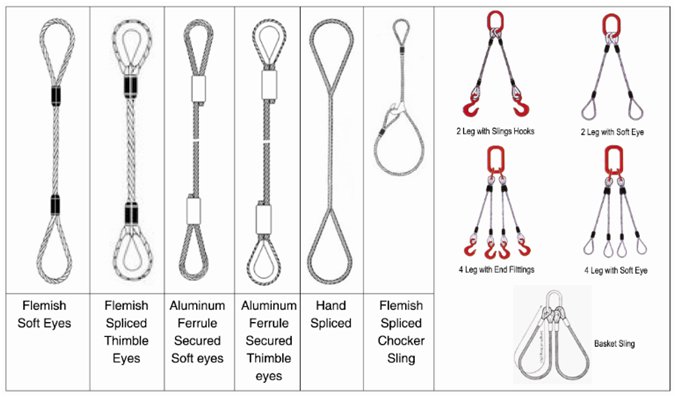

What are the main types of wire rope slings?

There are different types of slings. Each type suits specific lifting needs.

| Sling Type | Common Use | Key Feature |

|---|---|---|

| Single Leg Sling | Simple lifts | One attachment point |

| Double Leg Sling | Balanced lifting of long items | Two attachment points |

| Braided Slings | Higher capacity lifts | Multiple wire ropes braided together |

| Endless Slings | Choking or basket hitches | Continuous loop, no fixed end fittings |

Where are wire rope slings most often used?

Wire rope slings see wide use across various sectors. Their strength and adaptability make them invaluable.

Wire rope slings are used in construction, marine, mining, and oil and gas industries. They are essential for lifting heavy machinery and materials.

For example, in construction, large steel beams and concrete slabs must be lifted. Wire rope slings are perfect for this. They can handle the weight and rough conditions. On a shipyard, ships’ parts or heavy equipment are moved. Slings provide the necessary power.

How do construction sites use wire rope slings?

Construction sites are full of heavy lifting. Slings help move materials and equipment safely.

- Steel Erection: They lift large steel beams into place. Buildings go up faster and safer.

- Precast Concrete: Heavy concrete panels are moved using slings. This is for walls and floors.

- Equipment Movement: Diggers, cranes, and other machines get moved. Slings help loading and unloading.

What role do slings play in the marine industry?

The marine industry deals with huge weights and harsh environments. Slings are chosen for their resilience.

- Shipbuilding: They help assemble large ship sections. This happens in dry docks.

- Offshore Operations: Oil rigs and platforms need constant supply. Slings lift heavy pipes and equipment to them.

- Dockside Loading: They load and unload cargo from ships. This ensures quick turnaround times.

Why are wire rope slings preferred in mining?

Mining involves moving massive amounts of material. Conditions are often tough and dirty.

- Extraction: Slings lift excavated ore. They move it to processing areas.

- Equipment Installation: Large mining machines are assembled underground. Slings help place heavy components.

- Shaft Operations: They are used for deepening shafts or moving people and materials up and down.

What features should I look for in wire rope slings?

Choosing the right sling is important. Certain features ensure performance and safety.

Look for high quality, high tensile strength, and high breaking load. Also, check for compliance with industry standards and available certifications.

When Andri looked for solutions, he always asked about quality first. He knew that cheap slings could lead to big problems. He wanted to make sure they met strict standards.

How does quality affect sling performance?

Good quality means the sling lasts longer. It also means it is safer to use.

- Material Purity: High-purity steel wires offer better strength. They resist fatigue.

- Manufacturing Process: A well-controlled process leads to uniform products. This means reliable performance.

- Durability: High-quality slings withstand repeated use. They do not snap easily under stress.

What does “high tensile strength” mean for a sling?

Tensile strength is how much pull a material can take. For slings, it means how much force it can resist before breaking.

- Load Capacity: Higher tensile strength means a sling can lift heavier loads.

- Safety Margin: It provides a bigger safety buffer. This is important for unexpected stresses.

- Longer Life: Stronger slings are less likely to get damaged. They last longer.

Why are certifications important for wire rope slings?

Certifications show that a product meets certain standards. They give buyers confidence.

- Industry Compliance: Certificates like EN12385-4 show the product meets specific requirements.

- Trust and Reliability: They prove independent bodies have checked the product. This builds trust.

- Safety Assurance: They confirm the sling is safe for its intended use. This reduces accident risks.

Are there customizable options for wire rope slings?

Yes, wire rope slings can be customized to fit specific needs. This includes size, fittings, and even branding.

Customizable options include different lengths, end fittings, and even your company’s logo. This ensures the sling perfectly matches your lifting requirements.

Sometimes, standard products just do not fit. For special projects, custom slings are often needed. We understand this. We work with clients to make slings that are just right for their unique jobs.

What customization options are available for sling length and fittings?

The length of the sling is crucial. The type of end fitting also matters a lot.

- Length: Slings can be made to any required length. This depends on the lifting height and space.

- End Fittings: Various fittings are available. These include thimbles, eye hooks, and master links. Each fits a specific connection point.

- Plastic Impregnation: Some slings can be plastic impregnated. This protects the core from dirt and damage.

Can I have my company’s logo on the slings?

Branding is important for many businesses. Yes, you can add your logo.

- Brand Identity: Adding your logo reinforces your brand. It helps to identify your equipment.

- Professional Look: Branded slings look more professional. They show attention to detail.

- Asset Tracking: It can also help with tracking your assets on big sites.

What about specialized assemblies and other wire products?

Beyond standard slings, other wire products also offer specialized solutions.

- Specialized Assemblies: We can create unique wire rope assemblies. These are for complex lifting or pulling tasks.

- Piling Tools: Some projects need wire ropes for piling machines. These are high-strength ropes for heavy-duty ground work.

- Galvanized and Stainless Steel: For harsh environments, galvanized or stainless steel options are available. They resist corrosion.

Conclusion

Wire rope slings are essential lifting tools. They offer strength, safety, and versatility. My company, Aulone, strives to provide the highest quality solutions for all your heavy lifting needs.