Does making a strong wire rope sound complicated? It might seem so. But the process is very interesting. Knowing how it’s made can help you choose the best one.

Continuous loop wire ropes are made by splicing the ends of a single wire rope. This creates an endless loop. This method is common for slings and specialized lifting gear.

I recall a time a client asked me about the strength of our ropes. He wondered if endless loops were as strong. Sharing the manufacturing process helped him understand their quality.

How do you make a wire rope sling?

Making a wire rope sling involves specific steps. We make sure each sling is strong and safe. The process needs skill and precision.

To make a wire rope sling, we cut a wire rope to length. Then we form eyes at each end. These eyes are secured with sleeves or splices. This creates a functional loop.

When we talk about slings, it is crucial to understand different types. Each type has a specific use. For example, some slings are better for heavy lifting. Others are for delicate loads. It is important to match the sling to the job. This ensures safety and efficiency.

Types of Wire Rope Slings

| Sling Type | Common Use | Key Feature |

|---|---|---|

| Single Leg Sling | Basic lifting | One continuous length |

| Multi-Leg Sling | Distributes load, provides stability | Two or more legs from a master link |

| Endless Sling | Choking, basket, vertical hitches | No end fittings, continuous loop |

| Braided Sling | Increased flexibility | Multiple ropes braided together |

Essential Tools for Sling Fabrication

Fabricating slings requires specific tools. We use cutting tools for precise lengths. Swaging presses are used to secure sleeves. Measuring tools ensure accuracy. Safety equipment is also always used. This protects our workers.

What is the difference between an eye splice and a mechanical splice?

Understanding splices is important. They are key to a rope’s strength. There are two main ways to join rope ends. Each method has its own benefits.

An eye splice is made by weaving the rope strands back into themselves. A mechanical splice uses a metal fitting, called a swage, pressed onto the rope.

Eye splices are often used for traditional applications. They are known for their flexibility. Mechanical splices are faster to make. They offer very high strength. We use both methods depending on the rope’s purpose. For us at Aulone, quality is always the main goal.

Manual Eye Splicing Technique

Manual eye splicing is a skilled craft. It involves careful unwinding of strands. Then, these strands are re-woven into the rope body. This creates a strong and neat eye. This method is labor-intensive. But it results in a strong bond.

Mechanical Splicing Process

Our factory has modern swaging machines. These machines apply immense pressure. They press a metal sleeve around the rope ends. This creates a strong and permanent joint. This process is very efficient. It ensures consistent quality.

How do you select the best wire rope for your specific needs?

Choosing the right wire rope is crucial. Many factors must be considered. The wrong choice can lead to failure. It can also cause safety issues.

To select the best wire rope, you need to consider the application, breaking load, flexibility, and resistance to corrosion. Material, construction, and coating are also vital.

My experience with clients like Andri shows that specific needs vary greatly. He always prioritized strict quality control and certifications. This means for them, a compliant and certified rope is more important than just pricing. At Aulone, we always help our clients find the perfect match.

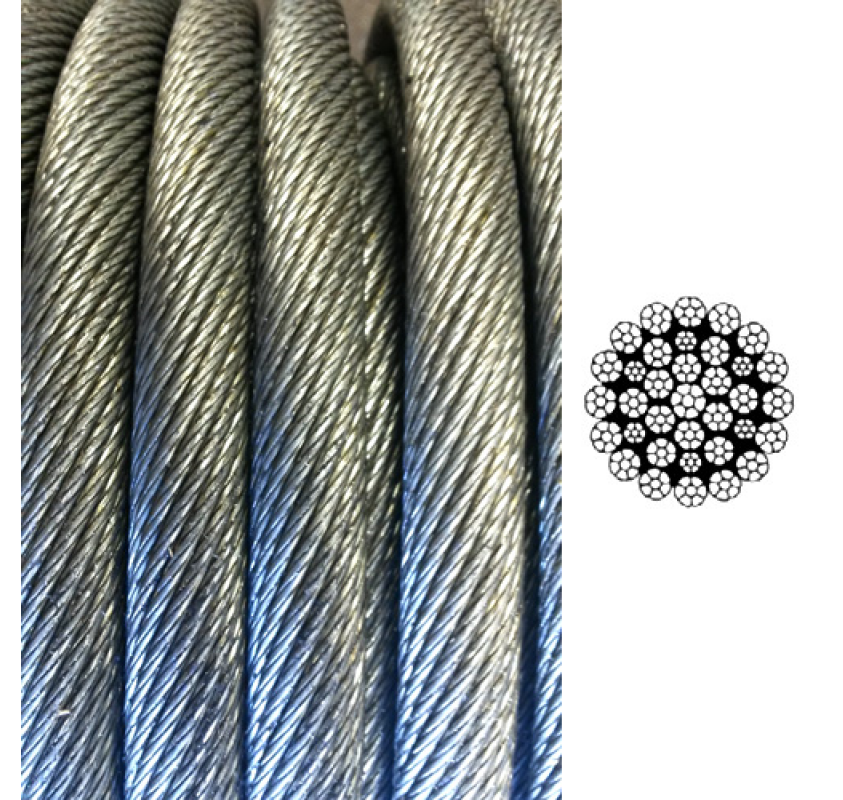

Understanding Wire Rope Construction

Wire ropes have different constructions. This refers to the number of strands and wires. For example, a 6×19 rope has 6 strands with 19 wires each. This construction affects flexibility and strength.

Importance of Material and Coating

The material of the rope wires matters a lot. Carbon steel is common. Stainless steel is used for corrosion resistance. Coatings like galvanization add protection. Plastic impregnation can also extend rope life.

Certifications and Standards

Certifications like EN12385-4 are vital. They ensure the rope meets safety standards. We can provide BV, CE, RMRS, DNV, and ABS certificates. These assure our clients of our high quality.

Conclusion

Making continuous loop wire ropes involves splicing and careful construction. Different methods provide specific benefits. Choosing the right rope demands understanding its features and purpose.