Selecting wire ropes isn’t just about their specs; it’s about how well they fit your equipment. Different industries and machines need different solutions. I’ll share practical insights to help you choose the best wire rope, starting with marine deck cranes, which face some of the toughest conditions.

Choosing the right wire rope for your marine deck crane ensures safe and efficient operations. It needs to withstand harsh environments and heavy loads.

Marine deck cranes are vital for loading and unloading ships. The wire rope is the heart of this operation, affecting both safety and speed. These cranes constantly deal with salty air, frequent starts and stops, and sudden heavy impacts. That’s why the wire rope needs to resist corrosion, wear, and twisting. I’ve put together guidance based on industry standards and real-world marine engineering practices to cover the key aspects of selecting and maintaining these essential ropes.

How Do I Balance Anti-Rotation and Flexibility in Crane Wire Rope Structure?

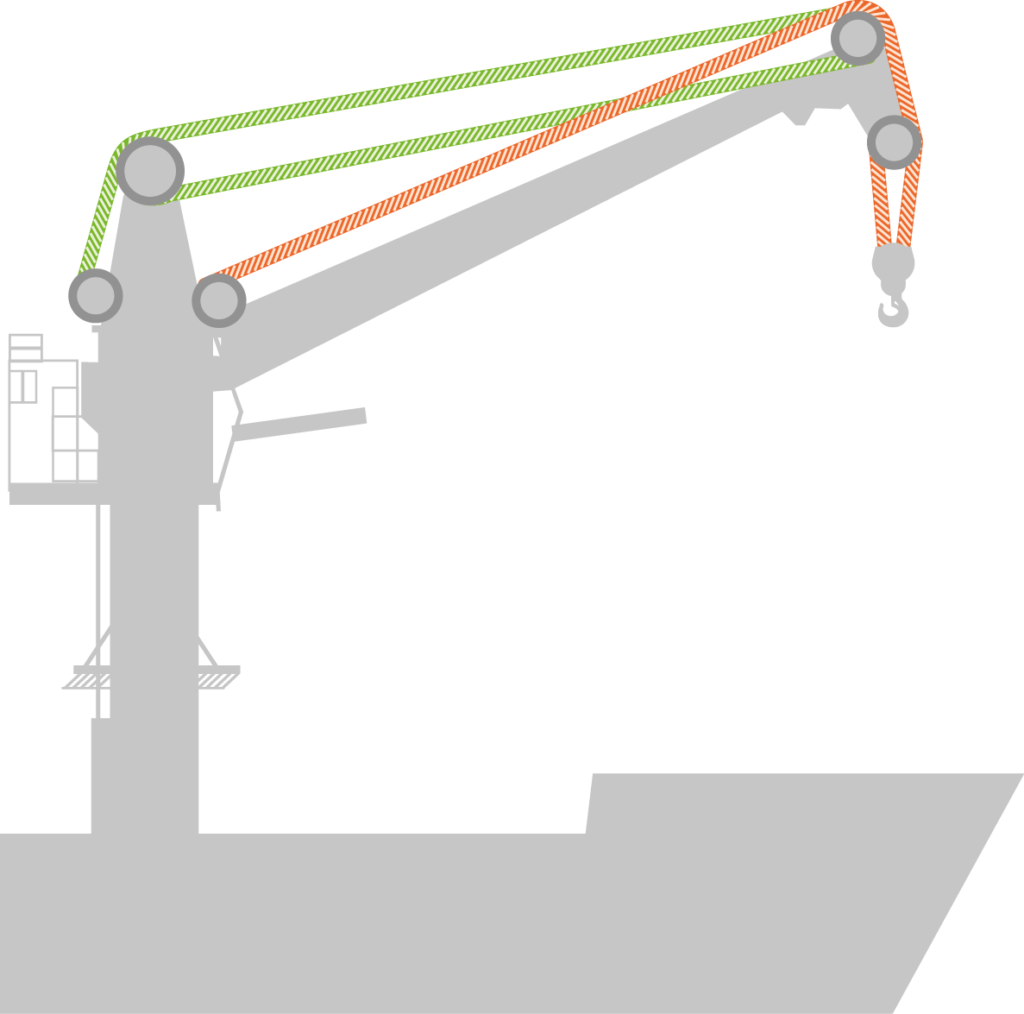

When considering wire ropes for deck cranes, understanding the specific needs of the hoisting and luffing mechanisms is key. The right structure dramatically impacts performance and longevity.

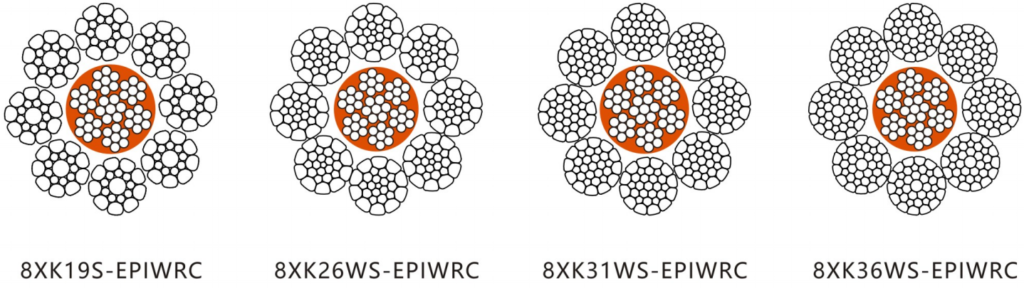

For hoisting, choose anti-rotation structures (like 35W×K7) to handle vertical loads and impacts without twisting. For luffing, opt for strand-laid constructions (like 8xK26WS-EPIWRC) for flexibility and wear resistance.

The primary applications for wire ropes on deck cranes are for hoisting and luffing. Each function has unique demands that influence the optimal rope structure. For hoisting, the rope must bear vertical loads and withstand dynamic shocks. This is where anti-rotation structures become crucial. These ropes are designed with multiple layers of strands twisted in opposite directions. This design counteracts the torque generated during lifting, preventing the rope from spinning or forming a “birdcage” shape, which is especially important when lifting loads without guides.

For the luffing mechanism, which involves frequent adjustments of the crane’s boom angle, flexibility and resistance to bending fatigue are paramount. Strand-laid rope constructions, such as those with 26 strands (like 8xK26WS-EPIWRC), offer a larger contact area between the wires. This reduces internal friction and extends the rope’s lifespan when it’s repeatedly bent.

It’s also vital to match the rope’s lay direction with the drum’s groove. Generally, if the drum has right-hand lay grooves, you should use a left-hand lay rope, and vice-versa. This seemingly small detail prevents structural deformation and potential failure due to incorrect rotational forces.

Structural Considerations for Hoisting and Luffing

To ensure optimal performance, the choice of wire rope structure needs to align with the specific demands of hoisting and luffing mechanisms.

| Mechanism | Primary Function | Recommended Structure Types | Key Benefits |

|---|---|---|---|

| Hoisting | Lifting and lowering loads, handling impacts | Multi-strand Anti-Rotation (e.g., 35W×K7) | Resists torque, prevents “birdcage” effect, stable for unguided loads |

| Luffing | Adjusting boom angle, frequent bending | Strand-Laid, High Strand Count (e.g., 8xK26WS-EPIWRC) | High flexibility, reduced internal friction, increased bending fatigue life |

Preventing Rope Twist: The Importance of Anti-Rotation Designs

Wire rope twisting can be a significant issue, especially in dynamic lifting applications. Understanding how anti-rotation structures work can prevent operational problems.

- Torque Counteraction: In hoisting, as the load is lifted, a torque is generated. Multi-strand ropes with opposing lay directions are engineered to counteract this torque. The inner and outer strands twist in opposite ways, effectively canceling out the rotational forces.

- Load Stability: This torque cancellation leads to a more stable lift. The load remains steady without excessive swinging or spinning, which is crucial for precise positioning and safety.

- “Birdcage” Phenomenon: Without proper anti-rotation design, the rope can deform into a spiral pattern resembling a birdcage. This is a sign of severe internal stress and can lead to sudden failure of the rope. Anti-rotation ropes are designed to prevent this.

Enhancing Bending Fatigue Life for Luffing Applications

The luffing mechanism involves constant bending and straightening of the wire rope as the crane boom moves. This repetitive stress, known as bending fatigue, can significantly shorten the rope’s lifespan.

- Wire and Strand Arrangement: Ropes designed for luffing, like those with a high number of strands (e.g., 26 strands) and a large lay, offer greater flexibility. The wires and strands are arranged to allow for smoother bending over sheaves and drums.

- Reduced Internal Friction: The construction minimizes the friction between individual wires and strands within the rope. This reduction in internal wear means the rope can endure more bending cycles before fatigue sets in.

- Material Properties: While structure is key, the quality of the steel wires themselves also plays a role in resisting fatigue. Using high-tensile strength steel that is also flexible is essential.

How Does Material and Anti-Corrosion Design Tackle Marine Environment Challenges?

The marine environment is unforgiving, filled with saltwater, humidity, and chemical agents that rapidly degrade unprotected steel. Therefore, selecting materials and incorporating anti-corrosion features is critical for extending wire rope life.

For marine applications, always opt for galvanized wire ropes with adequate zinc coating (Grade A or B) and consider independent wire rope cores (IWRC) or oil-impregnated synthetic fiber cores (FC) for enhanced protection.

The corrosive nature of the sea breeze and saltwater spray is a primary concern for any equipment operating in a marine environment. This harsh exposure can quickly lead to rust and corrosion, weakening the wire rope and compromising its safety. To combat this, material selection and design innovations are crucial.

Galvanized Wire Ropes: The First Line of Defense

Galvanization is the process of coating steel wires with a layer of zinc. This zinc layer acts as a sacrificial barrier, corroding before the steel does.

- Zinc Coating Grades: Different grades of galvanization exist, with Grade A offering a thicker coating and thus better corrosion resistance than Grade B. For prolonged exposure to marine conditions, selecting a rope with at least Grade A galvanization is advisable, meeting standards like GB/T 20118.

- Surface Finish: The quality and uniformity of the zinc coating are important. A smooth, consistent coating provides more reliable protection.

Core Materials: Supporting Strength and Durability

The core of a wire rope is its backbone, providing internal support and preventing crushing. In marine settings, the core also plays a role in protection against internal corrosion.

- Independent Wire Rope Core (IWRC): This is essentially a smaller wire rope used as the core. IWRC provides excellent resistance to crushing and deformation, which is beneficial for heavy-duty operations. It also offers good protection against moisture ingress into the core itself, though the steel core can still rust if exposed.

- Fiber Core (FC) with Oil Impregnation: Fiber cores, particularly synthetic fiber cores (FC), offer greater flexibility than IWRC. Impregnating these cores with a special lubricant or oil provides an additional barrier against moisture reaching the inner wires of the rope. This can help prevent internal corrosion and improve fatigue resistance.

The Role of Plastic Filling Layers

Some advanced wire ropes, like those produced by Aulone, incorporate a plastic filling layer between the core and the outer strands. This feature is particularly advantageous in demanding environments.

- Structural Stability: The plastic layer acts like a tight casing, stabilizing the rope’s structure. This stability helps maintain the rope’s shape and prevents premature wear caused by wires shifting against each other.

- Water and Dust Barrier: This filling layer effectively seals the core and the inner workings of the rope, preventing water and dust from penetrating. This is critical for stopping internal rust formation within the steel core, a common failure point in corrosive environments.

- Wire-to-Wire Abrasion Reduction: The plastic filler minimizes direct contact and friction between the outer wires and the core strands. This reduction in abrasion helps to increase the rope’s overall lifespan, especially under dynamic loading conditions.

How Do I Match Strength and Safety Factors to Specific Working Conditions?

Ensuring a wire rope has the correct tensile strength and is used with an appropriate safety factor is paramount for preventing failure and accidents. This requires understanding the loads the rope will carry and the relevant industry standards.

Higher tensile strength ropes (1960MPa or more) are recommended for lifting, while lower strength (1770MPa) can be suitable for luffing. Always adhere to safety factors of five or more for lifting, and check local regulations for specific requirements.

The operational demands on a wire rope dictate its required strength and the safety margins that must be maintained. This is not just about arbitrary numbers; it’s about ensuring the rope can handle the forces it encounters and has enough reserve capacity to remain safe even under unexpected stresses.

Tensile Strength: The Breaking Point

Tensile strength refers to a wire rope’s resistance to being pulled apart. It’s typically measured in Megapascals (MPa).

- Lifting Wire Ropes: For hoisting operations, where the rope directly bears the load and is subject to dynamic shock loads, a higher tensile strength is generally recommended. A minimum of 1960MPa is often suggested. For particularly heavy lifts or operations involving containers, where impact forces can be significant, ropes with a tensile strength of 2160MPa are preferred.

- Luffing Wire Ropes: The luffing mechanism, while still under load, involves more bending than direct pulling. Therefore, ropes with slightly lower tensile strength, around 1770MPa, can be adequate if they offer better flexibility and fatigue resistance. The trade-off here is balancing strength with the operational demands of flexibility.

Safety Factors: The Margin of Error

A safety factor is the ratio of a rope’s breaking strength to the maximum working load it will experience. It’s a critical design parameter that accounts for potential overloads, wear and tear, shock loads, and inaccuracies in load estimation.

- General Lifting: According to industry standards, a safety factor of at least five is typically required for general lifting operations. This means the rope’s breaking strength should be at least five times the maximum expected load.

- Hazardous Loads: When lifting hazardous materials or in applications where failure could have severe consequences (e.g., handling toxic substances or in specific mining operations), the safety factor is often increased to between six and eight.

- Luffing Mechanisms: For luffing mechanisms, the dynamic loads can be less severe than direct hoisting, and a slightly lower safety factor might be permissible, but regular inspections for bending fatigue are crucial. Always consult specific crane manufacturer guidelines and local maritime regulations, as these standards can vary.

Diameter Matching: Preventing Premature Wear

The diameter of the wire rope must be correctly matched to the diameters of the crane’s drum and sheaves (the grooved wheels the rope runs over). Incorrect sizing can lead to excessive wear and damage.

- Drum Diameter Ratio: The ratio of the drum diameter to the wire rope diameter should generally be 20:1 or higher. A larger drum provides a wider bending radius for the rope, reducing stress and extending its life.

- Sheave Groove Diameter: The diameter of the sheave groove should be slightly larger than the wire rope diameter, typically 5% to 10% larger. This ensures the rope seats properly in the groove without being pinched or crushed, which can lead to deformation and accelerated wear.

Conclusion

Selecting the right wire rope for marine deck cranes is crucial for safety and operational success. It requires a deep understanding of how rope structure, material properties, and proper sizing interact to withstand the demanding marine environment and lifting loads, ensuring reliability and longevity.