Are you struggling with unreliable wire ropes for your steel operations? It’s a common problem that causes costly downtime and safety concerns.

Aulone wire ropes offer superior tensile strength, exceptional durability, and certifications to meet stringent industry standards, ensuring peak performance and safety.

Don’t let subpar wire ropes hold back your production. Discover how Aulone can lift your steel business to new heights with our robust and dependable solutions.

What Makes Aulone Wire Ropes Stand Out in Steel Mills?

Many steel industry professionals are looking for wire ropes that can withstand extreme conditions. Ordinary ropes often fray or break under the immense pressure and heat of steel production.

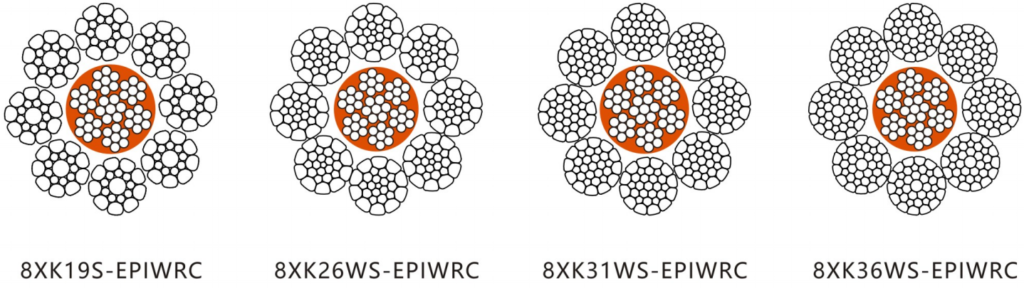

Our 8XK26WS-EPIWRC wire rope is engineered for the harshest environments. It boasts exceptional structural stability and fatigue life. This means it can handle the heavy loads of large metallurgical cranes, ensuring your operations run smoothly and safely.

Key Features of Aulone Wire Ropes for Steel Mills

To truly appreciate the value of our wire ropes, let’s break down the specifics that make them ideal for the demanding steel industry.

| Feature | Description | Benefit for Steel Industry |

|---|---|---|

| High Tensile Strength | Capable of withstanding immense pulling forces without deforming or breaking. | Ensures safe lifting of heavy materials, reducing the risk of accidents and component failure. |

| Exceptional Fatigue Life | Designed to endure repeated bending cycles without weakening. | Leads to longer service life, minimizing replacement frequency and associated costs. |

| High Breaking Load | The maximum load a wire rope can withstand before it breaks. | Provides a significant safety margin, crucial for heavy-duty lifting operations in steel plants. |

| Plastic Impregnated | Core is filled with a plastic compound to reduce internal friction and improve lubrication. | Enhances flexibility, reduces wear between strands, and protects against corrosion, extending rope life. |

| Galvanized Options | Steel wires are coated with zinc for enhanced corrosion resistance. | Protects the rope from rust and degradation, especially in the often humid or chemically exposed environments of steel mills. |

| Customizable Logo | Ability to brand the wire ropes with your company logo. | Enhances brand visibility and professionalism across your operations. |

| Certifications (BV, CE, RMRS, DNV, ABS) | Compliance with recognized international safety and quality standards. | Guarantees the rope meets rigorous specifications, essential for bidding on projects and satisfying regulatory requirements. |

| Structural Stability | Wire rope construction is optimized for maintaining its shape under load. | Prevents uneven wear and maintains consistent performance, crucial for precise material handling. |

| Resistance to Deformation | Resists crushing and deformation, even under high pressure. | Ensures the rope’s integrity when used with multi-layer spooling on drums, preventing premature failure. |

8XK26WS-EPIWRC Technical Datasheet

Standard tolerance: +2% to 4%, other tolerances and rope diameters available upon request.

| Nominal rope diameter | Approx mass | Minimum breaking force | ||||||

|---|---|---|---|---|---|---|---|---|

| Rope grade | ||||||||

| 1770 | 1960 | 2160 | ||||||

| mm* | Inch | kg/m | kN | t | kN | t | kN | t |

| 6 | 0.162 | 29.3 | 2.99 | 32.4 | 3.30 | 34.1 | 3.48 | |

| 6.4 | 0.184 | 33.4 | 3.41 | 36.9 | 3.76 | 38.8 | 3.96 | |

| 7 | 0.220 | 39.9 | 4.07 | 44.2 | 4.51 | 46.4 | 4.73 | |

| 8 | 5/16 | 0.288 | 52.1 | 5.3 | 57.7 | 5.9 | 60.6 | 6.2 |

| 9 | 0.364 | 66.0 | 6.7 | 73.0 | 7.4 | 76.7 | 7.8 | |

| 10 | 0.450 | 81.5 | 8.3 | 90.1 | 9.2 | 94.7 | 9.6 | |

| 11 | 7/16 | 0.544 | 98.6 | 10 | 109.1 | 11.1 | 114.6 | 11.7 |

| 12 | 0.648 | 117.3 | 12 | 129.8 | 13.2 | 136.3 | 13.9 | |

| 12.7 | 1/2 | 0.726 | 131.4 | 13.4 | 145.4 | 14.8 | 152.7 | 15.6 |

| 13 | 0.760 | 137.7 | 14 | 152.3 | 15.5 | 160.0 | 16.3 | |

| 14 | 0.882 | 159.7 | 16.3 | 176.7 | 18 | 185.6 | 18.9 | |

| 15 | 1.012 | 183.3 | 18.7 | 202.8 | 20.7 | 213.0 | 21.7 | |

| 16 | 5/8 | 1.152 | 208.6 | 21.3 | 230.7 | 23.5 | 242.4 | 24.7 |

| 17 | 1.300 | 235.5 | 24 | 260.5 | 26.5 | 273.6 | 27.9 | |

| 18 | 1.457 | 264.0 | 26.9 | 292.0 | 29.8 | 306.8 | 31.3 | |

| 19 | 3/4 | 1.624 | 294.2 | 30 | 325.4 | 33.2 | 341.8 | 34.8 |

| 20 | 1.799 | 325.9 | 33.2 | 360.5 | 36.7 | 378.7 | 38.6 | |

| 21 | 1.984 | 359.3 | 36.6 | 397.5 | 40.5 | 417.5 | 42.5 | |

| 22 | 2.177 | 394.4 | 40.2 | 436.2 | 44.5 | 458.3 | 46.7 | |

| 22.4 | 2.257 | 408.9 | 41.7 | 452.2 | 46.1 | 475.1 | 48.4 | |

| 23 | 2.380 | 431.0 | 43.9 | 476.8 | 48.6 | 500.9 | 51 | |

| 24 | 2.591 | 469.3 | 47.8 | 519.1 | 52.9 | 545.4 | 55.6 | |

| 25 | 2.812 | 509.3 | 51.9 | 563.3 | 57.4 | 591.8 | 60.3 | |

| 25.4 | 1 | 2.902 | 525.7 | 53.6 | 581.5 | 59.3 | 610.8 | 62.2 |

| 26 | 3.041 | 550.8 | 56.1 | 609.3 | 62.1 | 640.0 | 65.2 | |

| 27 | 3.279 | 594.0 | 60.5 | 657.0 | 67 | 690.2 | 70.3 | |

| 28 | 3.527 | 638.8 | 65.1 | 706.6 | 72 | 742.3 | 75.6 | |

| 28.6 | 1-1/8 | 3.680 | 666.5 | 67.9 | 737.2 | 75.1 | 774.5 | 78.9 |

| 29 | 3.783 | 685.3 | 69.8 | 758.0 | 77.2 | 796.3 | 81.1 | |

| 30 | 4.049 | 733.4 | 74.7 | 811.1 | 82.7 | 852.1 | 86.8 | |

| 31 | 4.323 | 783.1 | 79.8 | 866.1 | 88.3 | 909.9 | 92.7 | |

| 32 | 1-1/4 | 4.606 | 834.4 | 85 | 922.9 | 94 | 969.5 | 98.8 |

| 33 | 4.899 | 887.4 | 90.4 | 981.5 | 100 | 1031 | 105.1 | |

| 34 | 5.200 | 941.9 | 96 | 1042 | 106.2 | 1095 | 111.5 | |

| 35 | 1-3/8 | 5.511 | 998.2 | 101.7 | 1104 | 112.5 | 1160 | 118.2 |

| 36 | 5.830 | 1056 | 107.6 | 1168 | 119 | 1227 | 125 | |

| 38 | 1-1/2 | 6.496 | 1177 | 119.9 | 1301 | 132.6 | 1367 | 139.3 |

| 40 | 7.198 | 1304 | 132.9 | 1442 | 146.9 | 1515 | 154.4 | |

| 41.3 | 1-5/8 | 7.673 | 1390 | 141.6 | 1537 | 156.7 | 1615 | 164.6 |

| 42 | 7.935 | 1437 | 146.5 | 1590 | 162 | 1670 | 170.2 | |

| 44 | 8.709 | 1578 | 160.7 | 1745 | 177.8 | 1833 | 186.8 | |

| 45 | 1-3/4 | 9.109 | 1650 | 168.1 | 1825 | 186 | 1917 | 195.4 |

| 46 | 9.519 | 1724 | 175.7 | 1907 | 194.3 | 2003 | 204.2 | |

| 47.5 | 1-7/8 | 10.150 | 1838 | 187.3 | 2034 | 207.2 | 2136 | 217.7 |

| 48 | 10.364 | 1877 | 191.3 | 2077 | 211.6 | 2181 | 222.3 | |

| 50 | 2 | 11.246 | 2037 | 207.6 | 2253 | 229.6 | 2367 | 241.2 |

| 52 | 12.164 | 2203 | 224.5 | 2437 | 248.3 | 2560 | 260.9 | |

| 54 | 2-1/8 | 13.117 | 2376 | 242.1 | 2628 | 267.8 | 2761 | 281.3 |

| 56 | 14.107 | 2555 | 260.4 | 2826 | 288 | |||

| 58 | 15.133 | 2741 | 279.3 | 3032 | 309 | |||

| 60 | 2-3/8 | 16.194 | 2933 | 298.9 | 3245 | 330.6 | ||

| 62 | 18.10 | 3520 | 358.94 | |||||

| 64 | 19.10 | 3718 | 379.13 | |||||

| 66 | 20.40 | 3946 | 402.38 | |||||

| 68 | 21.60 | 4189 | 427.16 | |||||

| 70 | 2-3/4 | 22.90 | 4463 | 455.1 | ||||

Why Does Structural Stability Matter in Metallurgical Cranes?

Metallurgical cranes in steel plants operate under some of the most challenging conditions imaginable. They lift massive loads—sometimes exceeding 480 tons—in environments with extreme temperatures and abrasive materials. The structural stability of the wire rope is paramount here. A rope that deforms or loses its shape under load can lead to uneven wear, increased stress on certain strands, and ultimately, premature failure.

Our 8XK26WS-EPIWRC wire rope is built with this in mind. Its robust construction ensures that it maintains its integrity and load-bearing capacity even in these extreme scenarios. This stability translates directly into increased safety for personnel and equipment, reduced downtime for inspections and replacements, and more consistent operational performance.

How Does Fatigue Life Impact Your Crane’s Uptime

Consider the constant bending and unbending that a wire rope undergoes as a crane operates. This repetitive stress, known as fatigue, is a major factor in rope lifespan. A wire rope with poor fatigue resistance will break down internally long before it shows external signs of wear. This can lead to sudden, catastrophic failures.

The 8XK26WS-EPIWRC model is specifically designed to resist this fatigue. Its advanced construction allows it to endure many more bending cycles compared to standard ropes. For steel mills, this means fewer interruptions for rope replacement. It assures you of a longer service life, which directly contributes to higher crane uptime and overall productivity.

Understanding the Importance of High Breaking Load

The breaking load is a critical safety specification for any wire rope. It represents the minimum load at which a new, unused wire rope is expected to break. In steel operations, where loads are immense and safety is non-negotiable, exceeding the required breaking load is essential.

Our 8XK26WS-EPIWRC wire rope offers a very high breaking load. This provides a substantial safety margin, ensuring that the rope can handle unexpected surges in load or operating beyond its rated capacity without immediate failure. This is particularly important for applications like charging machines or ladle cranes where dynamic loads are common.

Benefits of Plastic Impregnation and Galvanization

The combination of plastic impregnation and galvanization in our wire ropes offers a dual-action protective system. Plastic impregnation fills the interstitial spaces within the rope’s core. This reduces internal friction between the strands as the rope bends and under load. It also serves as a barrier, preventing moisture and contaminants from reaching the core.

Galvanization, the zinc coating on the individual wires, provides excellent protection against corrosion. Steel mills can be environments prone to moisture and chemical exposure. The galvanized layer acts as a sacrificial barrier, corroding before the base steel, thus significantly extending the usable life of the wire rope and maintaining its strength.

How Does Aulone Support the Steel Industry’s Demands?

We are proud to support China’s steel industry. Our clients in this sector process approximately 132 million tons of steel annually. Our 8XK26WS-EPIWRC wire rope is specifically used on metallurgical cranes with capacities up to 480 tons.

The high structural stability and exceptional bending fatigue life of the 8XK26WS-EPIWRC make it capable of withstanding the extreme operating conditions found in steel mills. It consistently meets the high demands for safety and stability required by metallurgical cranes, achieving a long service life. This model offers an extremely high breaking load, very stable rope structure, excellent bending fatigue life, and superior resistance to crushing and abrasion, making it ideal for multi-layer spooling on drums.

What Certifications Guarantee Aulone Wire Rope Quality?

Ensuring that wire ropes meet rigorous international standards is crucial for safety. Many purchasing managers and buyers are concerned about compliance and the ability to demonstrate product quality.

We can provide necessary certifications like BV, CE, RMRS, DNV, and ABS upon client request. This ensures our wire ropes meet global quality and safety benchmarks.

How Do Competitor Ropes Compare in Durability?

When assessing wire ropes, it’s important to look beyond basic specifications. Many ropes offer good tensile strength but fail to address critical factors like fatigue life or resistance to crushing. Our focus on these details sets us apart.

Unlike ropes that might degrade quickly under constant flexing or begin to deform on the drum, our ropes are engineered for longevity. This means less frequent replacements and lower overall operational costs for our clients, a key consideration for companies like those who represent significant annual purchase volumes.

Conclusion

Aulone wire ropes deliver the strength, durability, and certification needed for demanding steel industry operations.

Thank you for your interest. Please feel free to contact me at info@wireropes.net or visit our website at www.wireropes.net for more information.