Selecting the right wire rope is crucial. It’s not just about the rope’s specs; it’s about fitting the equipment perfectly. This is why tailored solutions for different industries and machines are so important. We’ll explore selection for various equipment to answer your questions.

Choosing wire rope for your equipment matters. It ensures safety and efficiency. Getting this right means your operations will run smoothly and reliably.

Wire ropes are vital for heavy lifting, but picking the correct one can be tricky. Do you know what to look for in wire ropes for critical equipment like crawler cranes? Let’s find out together.

What Makes a Crawler Crane Wire Rope Selection Different?

Crawler cranes are workhorses in construction and lifting. They need reliable wire ropes to perform safely. The main lifting rope and the boom luffing rope have different jobs, so they need different features.

Understanding the distinct roles of hoist and luffing wire ropes is key to selecting the correct type for your crawler crane to ensure optimal performance and safety.

Let’s break down the specific requirements for each. We’ll look at structural designs, strength, and how standards influence the choice. This will help you make informed decisions for your crane operations.

Why is Anti-Rotation and High Tensile Strength Crucial for Hoist Wire Ropes?

The hoist wire rope directly lifts heavy loads. It faces dynamic loads, constant winding, and impacts. Therefore, its selection must prioritize resistance to rotation and high tensile strength.

Structural Choices for Hoist Ropes

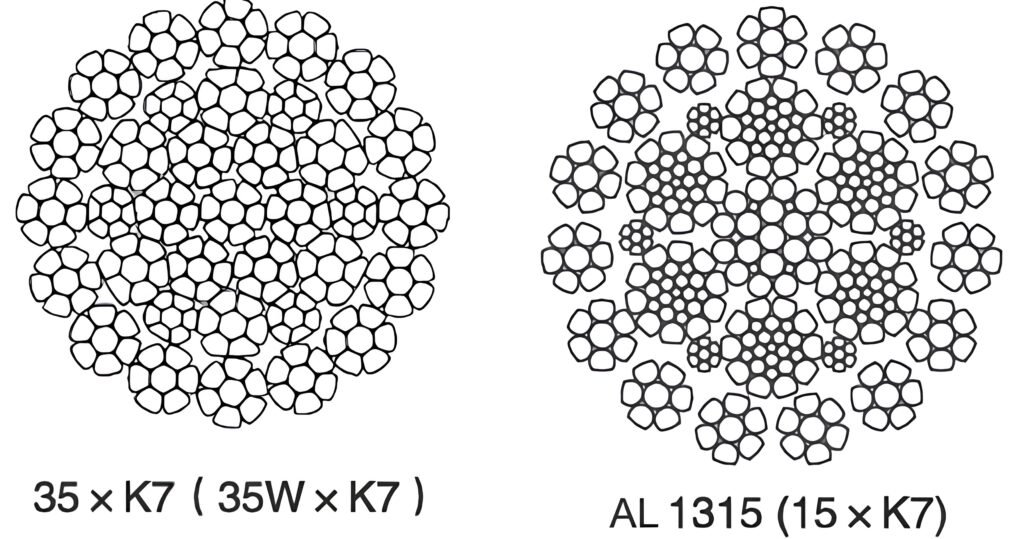

- 35W×K7/15×K7: These ropes have outer and inner strands twisted in opposite directions. This design counteracts rotational forces, preventing dangerous “bird-caging” or deformation. They are particularly suitable for lifting operations where the load is not guided, common in many construction scenarios.

- Compacted Strand Wire Ropes: These ropes feature strands with a compacted design. This reduces internal friction as the rope winds and unwinds. It leads to better wear resistance, making them ideal for frequent spooling and high-layer winding operations on the crane’s drum.

Strength and Standard Compliance

- Tensile Strength: It is recommended to use wire ropes with a tensile strength of at least 1960 MPa. For heavy-duty applications or those involving significant impacts, such as lifting prefabricated components, a strength of 2160 MPa is preferable.

- Safety Factor: For general lifting, a safety factor of 5 or higher is standard. However, when handling hazardous materials or in operations with a higher risk profile, this safety factor should be increased to 6-8.

How Do Flexibility and Fatigue Resistance Guide Luffing Wire Rope Selection?

The luffing wire rope adjusts the crane’s boom angle. It undergoes frequent bending and dynamic loading. Therefore, its selection should focus on flexibility and resistance to fatigue.

Structural Choices for Luffing Ropes

- Standard Strand Design: Ropes with finer wires in their strands are better suited for high-frequency bending. This design offers superior fatigue resistance. A good example is the 8x26WS structure wire rope, specifically the plastic impregnated version (EPIWRC).

- Plastic Impregnated (EPIWRC): Many of our products at Aulone feature a plastic layer between the core and outer strands. This layer acts like a supportive sleeve, stabilizing the rope’s structure. It increases the wire rope’s lifespan, especially in challenging environments. This protective layer prevents water and dust ingress, thus avoiding corrosion within the core. It also prevents direct contact between the steel wires, avoiding potential damage.

What are the Best Practices for Installation and Maintenance of Crane Wire Ropes?

Correct installation and consistent maintenance are vital for wire rope longevity and safety. Improper practices can lead to premature wear and potential failure.

Pulley Compatibility

- Pulley-to-Rope Diameter Ratio: The diameter of the pulley should be at least 20 times the diameter of the wire rope. This prevents excessive stress and deformation on the rope.

- Sheave Groove Diameter: The groove diameter on the pulley needs to be 5-10% larger than the wire rope’s diameter. This clearance ensures the rope seats correctly without being squeezed or chafing.

Regular Lubrication

- Lubricant Type: Use graphite-based or complex lithium-based greases. For luffing wire ropes, pay extra attention to lubricating the bending points to ensure adequate penetration. This is essential as these ropes flex constantly.

Maintaining these aspects ensures your wire ropes will perform reliably and safely, extending their service life and reducing overall operational costs for your company.

What Are the Key Product Features of Aulone Wire Ropes for Cranes?

At Aulone, we offer high-quality wire ropes designed for demanding crane applications. Our products meet international standards and can be customized to your specific needs. We understand the critical role wire ropes play in your operations, from safety to efficiency.

Our wire ropes provide high tensile strength and breaking loads, conforming to EN12385-4. We can also supply BV, CE, RMRS, DNV, and ABS certificates upon request, along with custom logo options.

We equip our factory with four production lines. This allows us to meet diverse customer demands and ensure timely delivery. Our capacity supports large-volume orders, making us a reliable partner for your procurement needs.

What Certifications and Customizations Does Aulone Offer for Wire Ropes?

We understand that different regions and industries have specific certification requirements. Aulone is prepared to meet these demands to ensure compliance and trust.

We can provide essential certifications like BV, CE, RMRS, DNV, and ABS, depending on client needs. Additionally, we offer customizable logo options on our products, allowing for brand visibility.

Our commitment to quality extends to meeting various international standards. We make sure our wire ropes are not only strong but also legally compliant in your target markets. This dual focus ensures both operational excellence and regulatory adherence.

How Does Aulone Ensure High Quality and Performance in Wire Ropes?

Quality is at the heart of what we do. We meticulously control our manufacturing processes to deliver superior wire ropes. From material selection to the final product, every step is monitored.

Our wire ropes are known for their high quality, superior tensile strength, and high breaking load capacity. They are compliant with EN12385-4, and we offer plastic impregnated and galvanized options for enhanced durability.

With four production lines, we maintain efficient and consistent manufacturing. This allows us to produce wire ropes that meet stringent performance criteria consistently across all batches.

What are Aulone’s Main Export Markets and Customer Bases for Wire Ropes?

Aulone proudly exports its high-quality wire ropes to a wide range of countries. We serve diverse industries and cater to various customer types, from large corporations to specialized distributors. Our global reach ensures that companies worldwide can benefit from our reliable products.

Our primary export markets include Singapore, Indonesia, Vietnam, Saudi Arabia, UAE, Russia, Australia, and Canada, among others. We serve purchasing managers, buyers, distributors, crane rental companies, and mining companies.

We understand that different customers have unique needs. Whether you represent a large corporation or a specialized distributor, we have the capacity and expertise to serve you effectively. Our focus is on building long-term partnerships based on trust and mutual benefit.

Who Are Aulone’s Typical Customers and What Are Their Pain Points?

We work with a diverse clientele, including purchasing managers from large corporations, buyers of wire ropes and slings, wire rope distributors, crane rental companies, and mining companies. These clients often operate on tight schedules and demanding project specifications.

Our typical clients often face challenges with pricing, stringent quality control demands, and the need for specific certifications to meet project or regulatory requirements.

For example, a client like Andri from Australia, who previously worked with German brands, values both reliable quality and competitive pricing. He might source locally for urgent needs but prefers imports for consistent quality and volume. His payment terms, typically 30% T/T in advance, reflect a practice of securing supply while managing cash flow. Understanding these pain points allows us to tailor our approach and product offerings effectively.

How Does Aulone Utilize Marketing Channels to Reach Potential Customers?

We employ a multi-channel marketing strategy to connect with our target audience effectively. Our aim is to be visible and accessible to those seeking high-quality wire rope solutions.

Our primary marketing channels include our official website, proactive client development through direct outreach, and leveraging search engines like Google for discoverability.

By maintaining a strong online presence and actively engaging with potential clients, we ensure that companies looking for reliable wire ropes can easily find and connect with us. This approach allows us to build relationships and understand specific customer needs from the outset.

Conclusion

Choosing the right wire rope for your crawler crane is essential for safety and performance. Consider structure, strength, and maintenance.

We are more than just suppliers; we are your partners in ensuring operational excellence and safety. Our commitment to quality, adherence to standards, and understanding of market needs makes Aulone the ideal choice for your wire rope requirements.

If you have any specific questions or need further assistance with your wire rope selection, please do not hesitate to contact us.