Choosing the right wire rope is crucial for any project. It’s not just about the rope’s specs; it’s about how it fits your equipment. Different machines and jobs need different solutions. We’ll explore how to pick wire ropes for various machines, starting with piling equipment.

Selecting wire ropes is not just about the rope’s own parameters and processes; it is more important that it can perfectly adapt to the applied equipment. Therefore, differentiated solutions for different industries and equipment are crucial. We will start from the selection of various subdivided industry equipment to answer questions for everyone: Piling machine wire rope selection.

Wire rope selection isn’t just about the rope itself; it’s about how well it matches your equipment. Different machines and jobs need tailored solutions. This guide focuses on choosing the right wire rope for piling machinery.

How Do I Select the Right Wire Rope for Piling Machines?

Picking the right wire rope for piling machines is vital for efficiency and safety. These machines work in tough conditions, so the ropes need to be strong and resistant. Let’s break down what makes a good piling machine wire rope.

For piling machines like rotary drilling rigs and hydraulic grabs, the wire rope choice directly impacts performance and safety. Rotary drilling rigs face complex conditions: mud, heavy loads, and constant rotation. This means the wire rope needs to resist wear, corrosion, and twisting. This article outlines the key aspects of selecting wire ropes for rotary drilling rigs based on industry standards and practical experience.

1. Structural Selection: Balancing Anti-Rotation and Wear Resistance

When choosing a wire rope for piling machines, its structure is key. The machine’s rotation puts a lot of twist on the rope. So, an anti-rotation design is essential. This design stops the rope from spinning or forming a “bird’s cage” shape during lifting.

Wire ropes for piling machines must handle the torsional stress from the rotating drill pipe, making anti-rotation structure a core selection criterion. Anti-rotation wire ropes use opposing lay directions for the outer and inner strands. The rope core and outer strands counteract each other’s torque, preventing self-rotation or “bird’s cage” deformation during lifting.

Recommended Structural Types

Finding the right structure balances strength and durability. Some structures are better for certain environments.

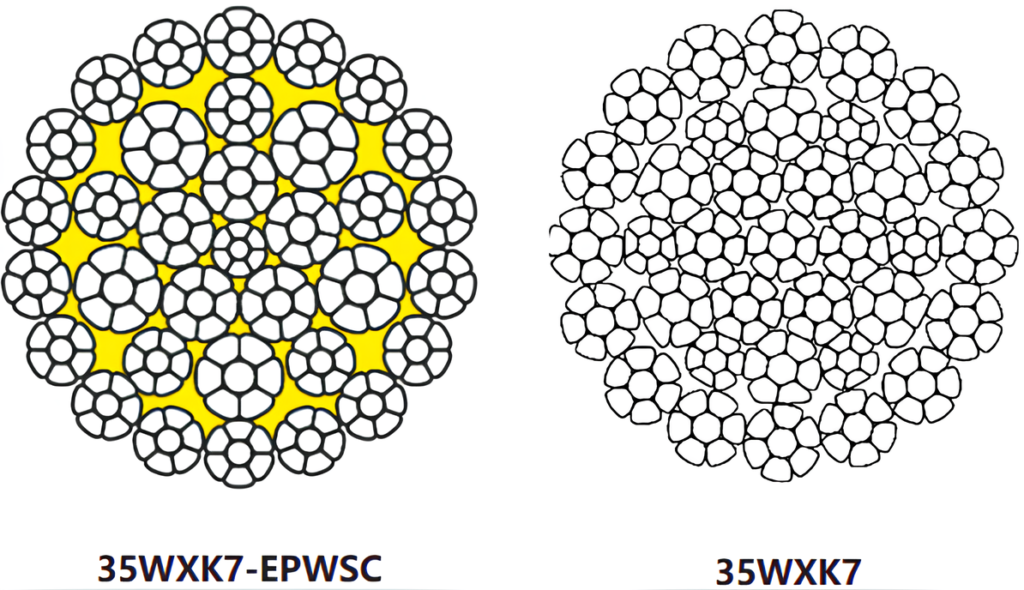

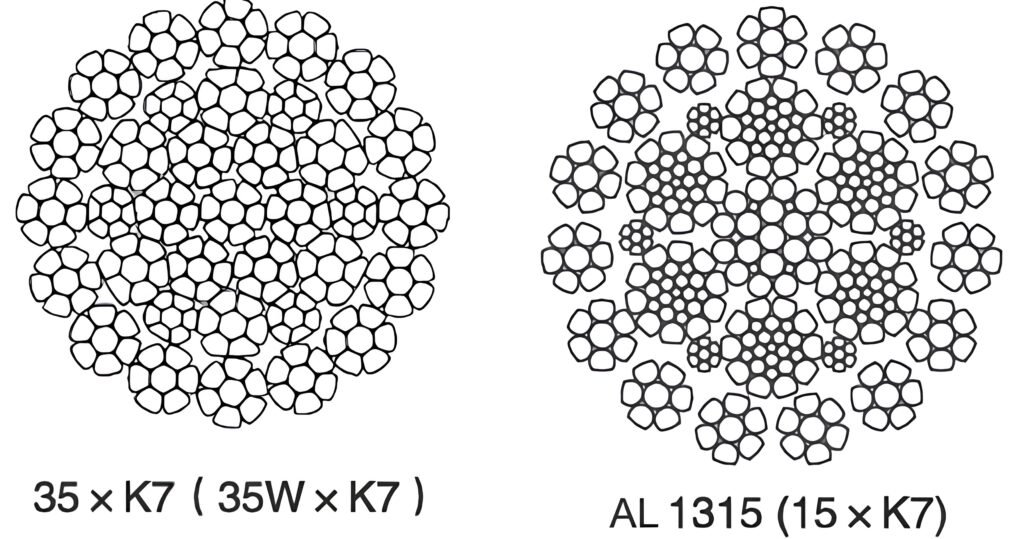

- 35W×K7/15×K7: This type has multiple layers of strands that contact each other. It has a high metal fill factor. This makes it resistant to rotation and wear. It’s especially good for environments with little mud but a lot of rocks and impacts. Examples include 35WXK7 and 35WXK7 P.

- Compacted Strand Wire Rope (e.g., 8XK26WS-EPIWRC): This design uses line contact between wires. This reduces friction between wires, extending the rope’s life.

2. Material and Surface Treatment: Combating Corrosion and Wear

Piling work often involves mud and corrosive substances. The wire rope needs protection against both corrosion and wear.

- Galvanized Wire Rope: The zinc coating helps prevent rust. This makes it suitable for jobs where the rope is often in mud.

- Wire Rope with Plastic Impregnated Core: We recommend a steel core with a plastic layer (IWRC). This improves resistance to crushing. It also prevents deformation when multiple layers wind around each other. The 35W×K7 -EPIWRC type is recommended here.

3. Diameter and Strength: Matching Equipment and Work Demands

Choosing the right diameter and strength is critical. It needs to fit the machine’s drum and pulleys and handle the job’s demands.

Diameter Selection

- Common Diameter Range: Typically between 24mm and 56mm. This depends on the size of the drum and pulleys.

- Groove Matching Principle: The drum diameter (D) and wire rope diameter (d) should meet the D/d ≥ 20 ratio. The pulley groove diameter should be 5% to 10% larger than the wire rope diameter. This reduces bending stress and crushing wear.

Strength and Flexibility Balance

- Tensile Strength: The strength grade should be at least 1770MPa for basic jobs. For hard rock or high-impact situations, 2160MPa is recommended.

- Safety Factor: When the single rope tension is high, a safety margin is needed. This prevents overload and breakage.

More Wire Rope Selection Knowledge Coming Soon!

We’ll keep sharing more tips on selecting wire ropes. Stay tuned for updates and keep an eye on our website for more insights.

Conclusion

Choosing the correct wire rope for piling machines is essential for operational safety, efficiency, and longevity. By understanding structural requirements, material properties, and matching specifications to your equipment, you can ensure optimal performance.