Are you finding that standard wire ropes just aren’t cutting it for your 2000-ton crawler crane’s heavy lifting needs? It’s incredibly frustrating when your equipment is held back by limitations that lead to downtime and potential safety issues, which is a common pain point when sourcing specialized components.

Generic wire ropes often fall short when critical performance metrics like lifespan, breaking strength, rotational stability, flexibility, structural integrity, and spooling are paramount. Only specialized wire ropes can deliver the advanced capabilities required to handle the immense forces of large-tonnage crawler cranes.

As a trusted manufacturer of premium wire ropes, Aulone is honored to be among the top choices for major original equipment manufacturers. We recognize the vital importance of your operations and are dedicated to helping you identify the ideal wire rope solution.

How Does Aulone Ensure Superior Performance for Your Crane’s Hoists?

Many crane operators grapple with the challenge of precisely matching wire rope specifications to the rigorous demands of high-capacity cranes. This mismatch frequently results in premature wear, decreased operational efficiency, and unexpected maintenance costs.

Aulone’s specialized wire ropes are meticulously engineered to provide the exceptional performance necessary for your heaviest lifting tasks. Our flagship products, including the 35WXK7 and 8XK26WS-WIRC-EPIWRC models, are specifically designed for critical applications such as main hoist and luffing hoist operations, ensuring optimal function.

What Are the Key Wire Rope Characteristics for Heavy Crawler Cranes?

When selecting wire ropes for heavy-duty crawler cranes, several critical attributes demand careful evaluation. These fundamental characteristics encompass the rope’s structural design, inherent material properties, and adherence to recognized international standards. Understanding these elements is crucial for making an informed decision to ensure safety and efficiency.

Why is the 35WXK7 the Preferred Choice for Main Hoists?

The 35WXK7 wire rope is specifically engineered for peak performance in the most demanding scenarios. Its robust construction is built to withstand the colossal loads inherent in main hoist operations, providing reliability and safety.

- Exceptional Tensile Strength: This rope boasts incredibly high tensile strength, a non-negotiable requirement for safely lifting massive weights.

- Superior Bending Fatigue Life: Engineered to endure numerous bending cycles, the 35WXK7 significantly extends its operational service life, reducing replacement frequency.

- Enhanced Abrasion and Squeeze Resistance: Its advanced construction offers superior protection against external forces, effectively preventing premature wear and deformation.

- Ideal for Multi-Layer Spooling: The rope’s design minimizes cross-over interference and potential damage when spooled in multiple layers on the drum, guaranteeing smooth and consistent operation.

- Flexible Usage Options: It offers operational versatility, as it can be utilized either in conjunction with a stress reliever or as a standalone component.

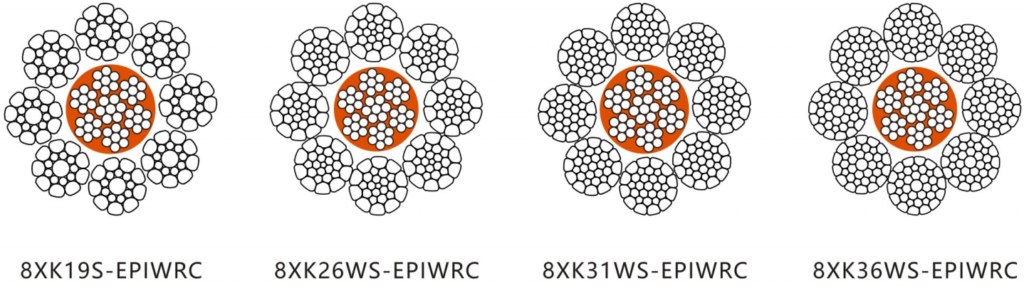

What Advantages Does the 8XK26WS-EPIWRC Offer for Luffing Hoists?

The 8XK26WS-EPIWRC stands out as a specialized 8-strand compacted wire rope, delivering unique and significant benefits specifically tailored for demanding luffing hoist applications.

- High Breaking Strength: It delivers exceptionally high breaking strength, which is vital for managing the dynamic and often fluctuating loads encountered during luffing operations.

- Stable Structure and Fatigue Resistance: The rope is designed to maintain a consistently stable structure, which translates into excellent bending fatigue results and ultimately a longer functional lifespan.

- Excellent Crushing and Abrasion Resistance: Featuring compacted outer strands and a plastic-impregnated core, it provides superior defense against the crushing forces and abrasive wear common in these applications.

- Superior Spooling Behavior: Its specialized design ensures perfect spooling characteristics on multilayer drums, effectively reducing tangling and preventing other operational disruptions.

- Important Note: For optimal performance and safety, this particular rope should not be used in conjunction with a swivel.

When Should You Consider Customizable Wire Rope Solutions?

Are you currently searching for a wire rope that perfectly aligns with your specific crane’s unique operational requirements and demands? Customization is indeed the most effective path when standard, off-the-shelf options do not quite meet your exact needs.

At Aulone, our dedicated engineering team is fully equipped to provide professional wire rope customization services. We believe in fostering close collaboration with you to meticulously optimize your crane’s performance and actively contribute to elevating industry standards through tailored solutions.

Why is Material Quality and Compliance So Critical?

We are committed to ensuring that all Aulone products consistently meet and exceed the most stringent quality control standards. Our wire ropes strictly adhere to the EN12385-4 standard, and we are able to readily provide necessary certifications, including BV, CE, RMRS, DNV, and ABS, upon client request, guaranteeing full compliance and peace of mind.

How Can You Optimize Your Crane’s Performance with Aulone?

To achieve maximum efficiency and operational excellence from your crane, it’s essential to meticulously consider the specific demands of your lifting tasks. Numerous factors, such as the precise load capacity, the required lifting height, and the unique operational environment, all play a crucial role in determining the most suitable wire rope selection.

Key Selection Factors to Consider:

| Feature | 35WXK7 | 8XK26WS-EPIWRC |

|---|---|---|

| Primary Use | Main Hoist Operations | Luffing Hoist Operations |

| Rope Structure | 35 Strands | 8 Strands |

| Core Type | Independent Wire Rope Core (IWRC) | Plastic Impregnated Rope Core |

| Tensile Purity | High | Very High |

| Fatigue Resilience | Excellent Bending Fatigue Life | Excellent Bending Fatigue Results |

| Wear Resistance | Very Good Abrasion and Squeeze Resistance | Very Good Crushing and Abrasion Resistance |

| Spooling Ability | Well-suited for multi-layer spooling | Exhibits perfect spooling on multilayer drums |

| Usage Caveat | Can be used with or without a stress reliever | Crucial: Not to be used with a swivel |

Personalizing Your Aulone Partnership Experience

We deeply understand that each of our clients possesses distinct and individual needs. This is precisely why we are pleased to offer customizable logo options directly on our products and maintain a flexible, client-centric approach to business development. Our primary objective is to cultivate strong, enduring partnerships built on trust and mutual success.

Conclusion

Aulone’s specialized wire ropes are meticulously engineered for the most demanding operational applications, ensuring that your heavy-lifting equipment receives the utmost in superior performance and unwavering reliability. Choosing Aulone means opting for enhanced safety, extended equipment life, and optimized operational efficiency.

We are committed to delivering not just wire ropes, but comprehensive solutions that empower your business. Our expertise and dedication to quality ensure you have the right tools for every heavy lift. Partner with Aulone for peace of mind and peak performance.