Struggling to pick the right marine rope? A wrong choice puts your vessel at risk. Understanding rope materials and construction is the key to safety on the water.

For boating, choose nylon for its stretch in dock lines and anchor rodes. Use low-stretch polyester for sails and rigging. For heavy-duty mooring or towing, consider galvanized or stainless steel wire rope for maximum strength.

I once saw a beautiful yacht damaged because of a cheap mooring line. It snapped in a mild squall. This showed me that investing in the right rope is not an expense; it’s essential insurance for your boat.

What are the Main Types of Marine Ropes?

The world of marine ropes can seem complex. But it mainly boils down to a few key types. Let’s break them down so you can choose confidently.

The main types are synthetic ropes like Nylon, Polyester, and Polypropylene, and high-modulus ropes like Dyneema. There are also traditional steel wire ropes. Each has specific uses based on strength, stretch, and resistance to elements.

When I walk through our Aulone factory, I see the incredible variety of ropes we produce. Each one is engineered for a specific job on the water. Understanding these differences is the first step for any boat owner or purchasing manager. It’s not about finding one “best” rope. It’s about finding the “right” rope for each task. Let’s dive deeper into the main categories you will encounter.

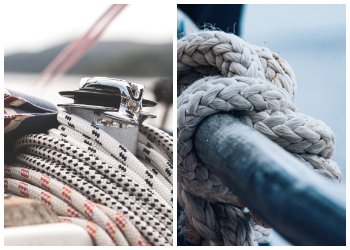

Synthetic Fiber Ropes

These are the most common ropes you’ll find on recreational and most commercial vessels today. They are generally easier to handle than wire rope and offer great performance for their cost.

- Nylon: This is probably the most popular choice for mooring and anchoring. Its key feature is stretch. When your boat is hit by a wave or surge at the dock, a nylon line stretches and absorbs the shock. This reduces the sudden, jarring load on your boat’s cleats and deck hardware. However, it’s not great for rigging where you need to control sail shape, as the stretch is a disadvantage there. It is very strong, but it does weaken slightly when wet.

- Polyester (Dacron): Think of polyester as the opposite of nylon in terms of stretch. It has very low stretch. This makes it a perfect choice for sheets and halyards on a sailboat. You want to be able to trim your sails precisely without the rope stretching and changing the sail’s shape. Polyester also has excellent resistance to UV sunlight, which is a major enemy of ropes on a boat. It holds its strength very well when wet.

- Polypropylene: This rope has one very unique feature: it floats. This makes it useful for safety lines, like heaving lines for life rings or as a painter for a small dinghy that you might tow. It is also very cheap. However, there are big downsides. Polypropylene is not very strong and degrades quickly in sunlight. I would never recommend it for any critical load-bearing application like docking or anchoring.

High-Modulus Synthetic Ropes

This is a newer category of “super” ropes. They are made from advanced materials and offer incredible performance, often replacing steel wire rope in many applications.

- Dyneema® / Spectra®: These ropes are made from Ultra-High Molecular Weight Polyethylene (UHMWPE). They are incredibly strong—stronger than steel wire of the same size—but are so light they float. They also have almost zero stretch. This combination makes them ideal for high-performance racing sailboats for halyards and control lines. Their high cost means they are usually reserved for situations where maximum performance and minimum weight are critical.

Steel Wire Ropes

Before synthetic ropes became popular, everything was done with steel wire rope. It is still the king for applications that require immense strength, durability, and abrasion resistance.

- Galvanized Steel Wire Rope: This is steel rope that has been coated in a layer of zinc to protect it from rust. It is extremely strong and cost-effective. You will find it used for standing rigging (the wires that hold up the mast), heavy-duty mooring pennants for large vessels, and in marine cranes.

- Stainless Steel Wire Rope: This type offers the best corrosion resistance. It’s made from steel alloys that include chromium, which prevents rust. It looks great and lasts a long time, but it is more expensive than galvanized wire. It’s very common for standing rigging on yachts, lifelines, and architectural uses where appearance matters. In our factory, we can create specialized assemblies using both galvanized and stainless steel rope for any marine project.

Here’s a simple table to help compare them:

| Rope Type | Key Feature | Common Uses |

|---|---|---|

| Nylon | Stretchy, strong | Dock lines, anchor lines |

| Polyester | Low stretch, UV resistant | Halyards, sheets, rigging |

| Polypropylene | Floats, inexpensive | Safety lines, dinghy painters |

| Dyneema® | Extremely strong, no stretch | High-performance racing rigging |

| Galvanized Steel | Very strong, abrasion resistant | Standing rigging, mooring, cranes |

| Stainless Steel | Corrosion resistant, strong | Standing rigging, lifelines, architectural |

How Does Material Affect a Rope’s Performance at Sea?

A rope is not just a rope. Its material dictates everything from how it handles to how long it lasts. The marine environment is harsh, so material choice is critical.

Material determines a rope’s strength, stretch, UV resistance, and abrasion resistance. Nylon stretches to absorb shock. Polyester resists sun and stretch. Polypropylene floats but weakens in sunlight. Steel offers immense strength but requires maintenance.

When a purchasing manager from a large shipping company contacts me, their questions are always about performance characteristics. They need to know exactly how a rope will behave under specific conditions because failure is not an option. Price is important, but performance and safety are paramount. Let’s look at the specific properties that are defined by a rope’s material.

Strength (Breaking Load)

This is the most fundamental property of any rope. It’s the amount of force a rope can take before it breaks. This is often listed as “tensile strength” or “minimum breaking load” (MBL). It’s crucial to choose a rope with a breaking load that is many times higher than the “safe working load” (SWL) it will experience. A typical safety factor is 5:1, meaning the rope’s breaking strength should be five times the heaviest load you expect it to handle.

In our factory, every batch of Aulone rope is tested on a massive machine that pulls it apart. This quality control test is not just for a certificate; it is our promise to the client that the rope will perform as specified.

Stretch (Elasticity)

Stretch, or elasticity, can be a rope’s best friend or worst enemy, depending on the job.

- High-Stretch Applications: As I mentioned, for an anchor line or a dock line, you want stretch. When your boat is tugged by a wave, a rope that stretches (like nylon) smoothly absorbs that energy. A low-stretch rope would transfer that entire shock load directly to your boat’s hardware, which could break a cleat right off the deck.

- Low-Stretch Applications: For a sailboat’s halyard, which pulls the sail up, stretch is terrible. If the halyard stretches, the sail’s shape becomes baggy and inefficient. You lose performance. That is why polyester or, for racers, Dyneema®, is the right choice. It stays firm and keeps the sail tight.

Resistance to Environmental Factors

A boat rope lives in a brutal world of sun, salt, and friction.

- UV Degradation: The sun’s ultraviolet rays break down the fibers of a rope over time, making it weaker. Polypropylene is the worst for this. It can become brittle and weak in just one season of sun exposure. Polyester, on the other hand, has excellent UV resistance, making it a reliable choice for lines that are always exposed.

- Abrasion: This is wear and tear from rubbing. A rope rubbing over a rough edge on a dock, a rocky seabed, or even just through a fairlead will slowly get worn down. Steel wire rope has the best abrasion resistance, hands down. For synthetic ropes, a tighter weave and certain coatings can improve it. We also offer ropes with a special plastic impregnation, which seals the rope and protects it from internal abrasion caused by salt and sand particles working their way into the core.

- Chemical and Saltwater Resistance: Most synthetic ropes like polyester and nylon are very resistant to saltwater and common chemicals. Steel wire rope, however, must be protected. That’s why we use galvanization (a zinc coating) or use stainless steel alloys. Without this protection, a steel rope would rust away quickly in a marine environment.

When Should You Choose Synthetic Rope vs. Wire Rope?

The choice between modern synthetic ropes and traditional wire ropes is a common question. Both have their place on a vessel. The key is knowing which job requires which tool.

Choose synthetic ropes for running rigging, dock lines, and anchor rodes due to their light weight and handling ease. Use steel wire rope for standing rigging, heavy-duty mooring, and crane operations where immense strength and abrasion resistance are paramount.

I often get requests from clients who are thinking of upgrading from wire to synthetic. Sometimes, it’s a great idea. Other times, wire rope is still the only sensible choice. The decision depends entirely on the application. You wouldn’t use a delicate racing rope to moor a huge cargo ship, and you wouldn’t use a greasy wire rope as the mainsheet on a small sailboat.

Where Synthetic Ropes Shine

The biggest advantages of synthetic ropes are their light weight, flexibility, and ease of handling. They don’t have dangerous broken wires (“fish hooks”), they don’t need to be lubricated, and they are much easier on your hands and on the boat’s finish.

- Running Rigging: This refers to all the lines that control the sails, like halyards and sheets. Polyester is the standard here. It’s strong, low-stretch, and durable. For racers looking for an edge, Dyneema® offers the same strength as steel at a fraction of the weight.

- Docking and Anchoring: Nylon is perfect for these jobs. It is strong, relatively inexpensive, and its natural stretch acts as a built-in shock absorber. Coiling a nylon dock line is a simple task, whereas handling a stiff wire rope for the same job would be a nightmare.

- Towing: While large ships may use wire for towing, many smaller commercial vessels and recreational boaters use high-strength synthetic ropes made of nylon or even UHMWPE for tow lines. They are much safer if they break, as they don’t have the same violent snap-back as a heavy wire rope.

Where Steel Wire Ropes Are Essential

Despite the advances in synthetic fibers, steel wire rope remains unbeatable for some tasks. Its incredible strength, low stretch, and resistance to abrasion and cutting are properties that synthetics still struggle to match in some contexts.

- Standing Rigging: These are the wires that support a sailboat’s mast (shrouds and stays). They are under constant, high tension and must have virtually zero stretch. Stainless or galvanized wire rope has been the trusted material here for a century for good reason.

- Heavy Mooring: For large commercial vessels, permanent moorings, or situations with very rough conditions (like on an oil rig), steel wire rope provides the ultimate security and durability against abrasion on the seabed.

- Cranes and Lifts: Any crane on a ship or at a port uses wire rope. Our

Aulonecrane wire ropes are designed for this. They can handle immense loads day after day, and they are resistant to the crushing and abrasion that occurs on winch drums and sheaves.

Here is a side-by-side comparison to make the choice clearer.

| Feature | Synthetic Rope (e.g., Polyester/Nylon) | Steel Wire Rope |

|---|---|---|

| Strength-to-Weight | Very High | High |

| Handling | Easy, flexible, soft on hands | Difficult, can be stiff, requires gloves |

| Stretch | Varies by material (High to Low) | Very Low |

| UV Resistance | Good (Polyester) to Poor (Polypropylene) | Excellent |

| Abrasion Resistance | Moderate | Excellent |

| Maintenance | Rinse with fresh water | Requires regular cleaning and lubrication |

| Primary Use Cases | Running rigging, dock lines, anchors | Standing rigging, cranes, heavy mooring |

What Certifications Should You Look For in Marine Ropes?

How do you know a rope is truly high-quality? You can’t just judge by looks. Certifications are your guarantee of performance and safety, approved by independent bodies.

Look for ropes compliant with standards like EN12385-4 for steel wire rope. Also, seek certifications from marine classification societies like DNV, ABS, or RMRS. These ensure the rope meets strict international quality and safety criteria.

This is a point I discuss constantly with my clients, especially purchasing managers like one I work with from Australia. For them, quality control is not just a preference; it’s a requirement. A certificate is not just a piece of paper. It is an assurance that the product has been made to a specific, verifiable standard. It’s proof that you are getting what you paid for.

International Manufacturing Standards

These standards define the “how” of making a rope. They cover everything from the quality of the raw material to the manufacturing process and testing procedures.

- EN 12385: This is a key European Standard for steel wire ropes. For example,

EN12385-4specifically covers steel wire ropes for cranes. When you see this on one of our ropes, it means it has passed the strict safety and performance requirements for lifting applications in Europe. - ISO Standards: The International Organization for Standardization sets global standards for many products, including ropes.

ISO 2307, for instance, specifies the methods for determining the physical and mechanical properties of fiber ropes.

Marine Classification Societies

These are independent organizations that set technical standards for the construction and operation of ships and offshore structures. If a part is going on a classed vessel, it often needs to be approved by one of these societies.

- DNV (Det Norske Veritas): A highly respected society, particularly strong in the European, offshore, and maritime sectors.

- ABS (American Bureau of Shipping): A leading classification society, particularly influential in the Americas and for offshore projects.

- RMRS (Russian Maritime Register of Shipping): Essential for any client supplying to projects in Russia or to vessels flagged under the Russian register.

A few years ago, a new client from Russia approached us for a very large order of specialized mooring ropes. Their primary requirement was that every single rope had to come with a full RMRS certificate. Because we have the capability to work with these societies and provide full certification, we were able to secure the contract. It showed me again how crucial these documents are for business in the global marine industry.

Mill Test Certificates

This is the most direct proof of quality. A Mill Test Certificate is a quality assurance document provided by the manufacturer (Aulone, in our case) that shows the test results for the specific batch of rope you are buying. It will list the actual measured breaking strength, the material composition, and the standard it was made to. We provide one with every order of our wire rope. It is your proof that the rope meets and often exceeds the specifications.

How Do You Properly Maintain Your Marine Ropes?

Buying a good rope is only half the battle. Proper maintenance can double its lifespan and, more importantly, ensure it doesn’t fail you when you need it most.

Regularly rinse synthetic ropes with fresh water to remove salt and dirt. Store them away from sunlight. For wire ropes, clean them and apply appropriate lubricant to prevent corrosion and reduce internal friction. Always inspect for damage before use.

I have seen perfectly good, expensive ropes ruined in a single season due to neglect. I have also seen well-maintained ropes last for over a decade. A little care goes a long way. Think of it as protecting your investment and your safety. The process is different for synthetic and wire ropes.

Maintenance for Synthetic Ropes

The biggest enemies of synthetic ropes are UV light, salt, and abrasion.

- Cleaning: Salt crystals are abrasive and can act like tiny knives, cutting the rope’s fibers from the inside out. The best and simplest thing you can do is rinse your ropes with fresh water after they are exposed to saltwater. For a deep clean, you can soak them in a bucket with a mild soap, then rinse thoroughly.

- Inspection: Before and after each use, run the rope through your hands. Feel for stiff spots, chafed areas, cuts, or areas where the fibers look melted or fused together (a sign of high friction). If you notice significant fuzziness all over the rope, it means it’s getting old and losing strength. Any damage means the rope’s strength is compromised.

- Storage: Sunlight is a killer. When not in use, store your ropes in a rope bag or in a locker, away from direct sunlight. Coil them neatly and avoid piling heavy or sharp objects on top of them.

Maintenance for Steel Wire Ropes

For wire ropes, the main enemies are corrosion (rust) and internal friction.

- Cleaning: Before you can inspect or lubricate a wire rope, it needs to be clean. Use a sturdy wire brush to remove old, dried grease, dirt, and any surface rust. This will allow you to see the condition of the rope itself.

- Inspection: This is critical. Wear thick leather gloves for protection. Run your gloved hand slowly along the length of the rope. You are feeling for any broken wires, which will stick out and are known as “fish hooks.” Look for kinks, crushed areas, or any sign that the rope’s shape is distorted. Also, look for signs of advanced corrosion. Even one or two broken wires in a small area can be a sign that the rope should be replaced.

- Lubrication: A wire rope is a machine with many moving parts (the strands and wires). It needs lubrication to move smoothly and to protect it from corrosion. You need to use a proper penetrating rope lubricant, not just any grease. The right lubricant will work its way to the core of the rope, protecting it from the inside out.

Here is a simple checklist for your reference.

| Rope Type | Cleaning | Inspection | Storage/Lubrication |

|---|---|---|---|

| Synthetic | Rinse with fresh water after use. | Look for chafing, cuts, stiff spots, discoloration. | Store coiled, in a dark, dry place (e.g., rope bag). |

| Steel Wire | Clean with a wire brush to remove debris. | Feel for broken wires, kinks, and corrosion. | Apply a penetrating rope lubricant regularly. |

Conclusion

Choosing the right marine rope and maintaining it properly is fundamental to boating safety. Understand the materials and match the rope to the task for peace of mind.