The oil and gas industry is incredibly demanding. Choosing the wrong wire rope can lead to dangerous failures and costly downtime. You need a rope that guarantees safety and reliability.

The best wire rope for oil and gas must handle extreme loads, resist harsh corrosion, and meet strict safety standards. Key factors include its construction, material, core type, and specific lubrication.

I once had a client come to me after a near-disaster offshore. Their story made me realize that selecting the right rope isn’t just a technical choice. It’s a critical safety decision.

What Specific Challenges Do Wire Ropes Face in Oil and Gas Environments?

The environment in oil and gas operations is relentless. Your wire rope is constantly under attack from many forces. It is important to know what these silent destroyers are.

Wire ropes in the oil and gas sector mainly face extreme tension from heavy lifting, severe corrosion from saltwater and chemicals, and abrasion from contact with equipment.

The Battle Against Corrosion

Corrosion is a constant enemy for wire ropes, especially in oil and gas. There are two main types you will face. The first is environmental corrosion, like from saltwater on an offshore platform. The second is chemical corrosion, from things like sour gas (H₂S), which can make steel very brittle.

We have two main defenses against this.

- Galvanization: We can coat the steel wires with a layer of zinc. This

galvanized wire ropesacrifices the zinc coating to protect the steel underneath. - Plastic Impregnation: We can fill all the empty spaces inside the rope with a special plastic. This creates a barrier, sealing the lubricant in and sealing corrosive elements out. This

plastic impregnatedrope offers fantastic protection.

Here is a simple comparison:

Table: Corrosion Resistance Methods

| Feature | Standard (Bright) Rope | Galvanized Rope | Plastic Impregnated Rope |

|---|---|---|---|

| Protection Mechanism | Oil/Grease only | Sacrificial Zinc Layer | Complete Plastic Barrier |

| Best For | Dry, low-corrosion environments | Offshore, humid environments | Extremely corrosive areas, marine use |

| Lifespan in Harsh Areas | Short | Good | Excellent |

Managing Extreme Loads and Fatigue

A wire rope on a drilling rig is not just holding a static weight. It is constantly moving, lifting, and lowering immense loads. This creates dynamic forces and causes fatigue. The individual wires bend over sheaves and drums thousands of times.

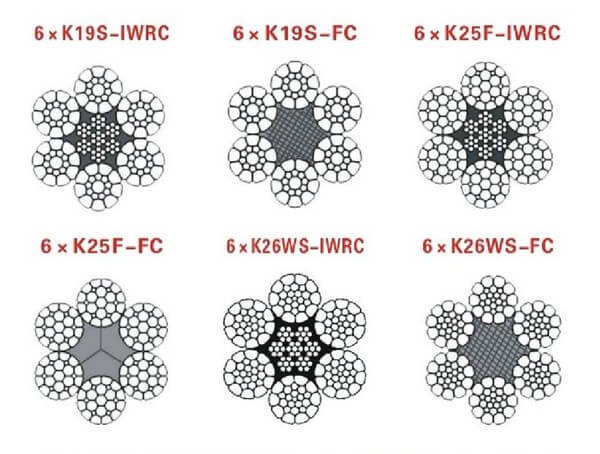

The rope’s construction is key to fighting fatigue. For example, a 6x36 WS IWRC construction has many outer wires. This design spreads the wear over a larger area. It makes the rope more flexible and resistant to bending fatigue. The Independent Wire Rope Core (IWRC) also adds significant strength and helps the rope keep its shape under heavy load. A high breaking load is essential, but fatigue resistance is what ensures a long service life.

Combating Abrasion and Crushing

Abrasion happens when the rope rubs against something. This could be the grooves of a sheave or multiple layers of rope grinding on a winch drum. This friction wears away the outer wires and reduces the rope’s diameter and strength.

Crushing happens when the rope is squeezed under high pressure on a drum. A rope with a soft core can be flattened, permanently damaging it. This is why an IWRC is so important in most oil and gas applications. The solid steel core provides excellent support from the inside, helping the rope maintain its round shape.

Table: Core Type Comparison for Oil and Gas

| Core Type | Independent Wire Rope Core (IWRC) | Fiber Core (FC) |

|---|---|---|

| Crush Resistance | Excellent | Poor |

| Tensile Strength | Higher | Lower |

| Flexibility | Good | Excellent |

| Typical Use | Drilling lines, crane ropes | Applications needing high flexibility |

| Recommendation for Oil & Gas | Highly Recommended | Not usually for main load lines |

Which Types of Wire Ropes Are Best for Onshore and Offshore Drilling?

Offshore and onshore work might seem similar. But their needs for wire rope can be very different. You need to know how to pick the right rope for your exact job site.

Offshore drilling often needs ropes with the best corrosion resistance, like a galvanized or plastic-impregnated rope. Onshore jobs might focus more on abrasion and crush resistance. Both need high tensile strength.

Key Ropes for Offshore Platforms

Offshore platforms (like jack-ups and semi-submersibles) are surrounded by saltwater. This is the most corrosive natural environment. Ropes here must be built to survive.

- Mooring Lines: These ropes hold the platform in place. They need high strength and amazing corrosion resistance.

Marine wire ropewith heavy galvanization or a plastic sheath is common. - Crane Ropes: Cranes on platforms move supplies and equipment. These ropes need to be strong, flexible, and resistant to rotation, especially for deepwater lifts.

- Drilling Lines: This is the main rope for drilling operations. It needs a very high

breaking load, excellent fatigue resistance, and good crush resistance. Aplastic impregnatedIWRCrope is a top-tier choice here.

Table: Recommended Rope Specifications for Offshore Applications

| Application | Recommended Construction | Key Features |

|---|---|---|

| Main Crane Hoist | 35×7 Class Rotation Resistant | High Breaking Load, Rotation Resistant |

| Drilling Line | 6×26 WS IWRC | Crush Resistance, Fatigue Resistance, High Strength |

| Mooring Line | 6×36 WS IWRC | Very High Corrosion Resistance, High Strength |

Essential Ropes for Onshore Rigs

Onshore rigs are not exposed to saltwater. But they face dust, dirt, and extreme temperatures. Abrasion and crushing are often the biggest problems here.

- Drilling Lines: The rope spools on and off a drum constantly. An

IWRCis critical to prevent crushing. Good lubrication is the main defense against dust and moisture. - Sand Lines: These are smaller ropes used for lighter work. They need to be tough and abrasion-resistant.

- Crane Ropes: Similar to offshore, but the focus is more on strength and abrasion resistance rather than extreme corrosion protection. A standard

IWRCrope with a quality lubricant is often enough.

Table: Recommended Rope Specifications for Onshore Applications

| Application | Recommended Construction | Key Features |

|---|---|---|

| Drilling Line | 6×19 S or 6×26 WS IWRC | Excellent Crush Resistance, Abrasion Resistance |

| Well Servicing Line | 19×7 or 35×7 Rotation Resistant | Rotation Resistant, Flexible |

| Rig Support Cranes | 6×36 WS IWRC | Flexibility, Good Strength, Abrasion Resistance |

Why Is Compliance with Standards Like API 9A So Important?

You will see codes like API 9A or EN12385 on a rope’s specification sheet. These are not just letters and numbers. They are your guarantee of safety and quality.

Following a standard like API Specification 9A ensures a wire rope meets the industry’s minimum needs for performance, safety, and quality. It provides reliability in a field where failure is not an option.

What is API Specification 9A?

API stands for the American Petroleum Institute. API Specification 9A is their global standard for the Specification for Wire Rope. This document is the rulebook for making high-quality wire rope for the petroleum industry.

It tells manufacturers:

- What materials to use.

- How to construct the rope.

- What the final dimensions should be.

- How to test the rope to prove its strength.

When a rope is API 9A compliant, it means it was made and tested according to these strict rules. This is the benchmark for quality in the oil and gas world.

Beyond API: Other Important Certifications

While API 9A is key for oil and gas, other certifications add more trust. For example, EN12385-4 is a European standard specifically for crane wire rope. It has very detailed requirements for safety.

We can also provide third-party inspection certificates. A company like ABS (American Bureau of Shipping), DNV (Det Norske Veritas), or BV (Bureau Veritas) can independently witness the testing of a rope. They then issue their own certificate. This tells you that an independent expert has confirmed the rope’s quality. For many large corporations, this is a requirement.

What Does a Certificate Actually Tell You?

A manufacturer’s Mill Test Certificate (MTC) is a rope’s “birth certificate.” It contains all the critical information from its production and testing.

Table: Understanding a Wire Rope Certificate

| Certificate Section | What It Means for You |

|---|---|

| Nominal Diameter | The stated size of the rope, for example, 32mm. |

| Construction | The build of the rope, like 6x36 WS IWRC. |

| Tensile Grade | The strength of the steel wire, like 1960 N/mm² or 2160 N/mm². |

| Minimum Breaking Load (MBL) | The guaranteed force the rope must hold before breaking. |

| Actual Breaking Load | The force the rope actually held during a destructive test. This must be higher than the MBL. |

| Standard | The rulebook it was made to, for example, API 9A. |

How Do Lubrication and Maintenance Extend the Life of Oil and Gas Wire Ropes?

A brand new wire rope looks very strong. But without the right care, its service life can become very short. The secret to a long life is proper care.

Correct lubrication and regular maintenance are critical. Lubrication cuts down on internal friction and protects from corrosion. Regular checks find damage early. This prevents bad failures and gets the most value from the rope.

The Dual Role of Lubrication

Lubrication performs two jobs at the same time.

- Internal Protection: A wire rope is a machine with many moving parts. The individual wires and strands rub against each other when the rope bends. Lubricant gets between these parts to reduce friction and wear.

- External Barrier: The lubricant also creates a protective coating on the outside of the rope. This barrier seals out moisture, dirt, and chemicals that would cause corrosion.

A rope that runs dry will wear out from the inside very quickly.

Factory Lubrication vs. Field Re-lubrication

The most important lubrication happens when the rope is made. At our factory, we inject a special lubricant into the rope’s core during the manufacturing process. This ensures every single wire is coated. For the best protection, the plastic impregnated ropes seal this factory lubricant in for life.

But even the best ropes may need more lubrication in the field. When you re-lubricate, you must first clean the rope to remove dirt. Then, apply a lubricant that can penetrate into the rope. Using a heavy grease that only sits on the surface can trap moisture inside, making corrosion worse.

A Basic Inspection Checklist

You should inspect your ropes regularly. Look for any signs of damage. Finding a problem early can prevent an accident.

Table: Simple Visual Inspection Guide

| Check For… | Why It’s a Problem |

|---|---|

| Broken Wires | This is a clear sign of fatigue or mechanical damage. |

| Corrosion (Rust) | Shows that the rope’s protection has failed. It weakens the rope from the inside. |

| Reduction in Diameter | This can mean the core has failed or there is extreme external wear. |

| Kinking or Crushing | This is permanent damage. The rope has lost a lot of its strength and must be replaced. |

What Are the Key Factors to Consider When Selecting a Wire Rope Supplier?

The wire rope itself is only half of the story. The partner you choose to supply that rope is just as important. So, what should you look for in a good supplier?

A great supplier has proven manufacturing experience, strong quality control, and third-party certifications. They should also provide technical help, customization, and have a good history in the oil and gas sector.

Manufacturing Capability and Experience

You want a supplier who is an expert manufacturer, not just a middleman. An established factory has control over the entire process, from the raw material to the final product. For example, our Aulone factory has four complete production lines. This gives us control over quality and delivery schedules.

Experience with exporting is also a very good sign. A supplier who exports to countries like Singapore, Russia, and Canada understands international standards and logistical needs. It proves they can meet the requirements of demanding clients worldwide.

Quality Control and Certification

This is not negotiable. Your supplier must be able to prove their quality.

- They must provide a Mill Test Certificate (MTC) for every single rope.

- They must have a clear quality control system in place.

- They must be willing and able to get third-party certificates from agencies like

ABS,DNV, orBVif you need them.

This transparency is how you build trust. It shows the supplier is confident in their product.

Table: Supplier Red Flags vs. Green Flags

| Red Flags (Warning Signs) | Green Flags (Good Signs) |

|---|---|

| Cannot provide a test certificate. | Provides a detailed MTC for every rope. |

| Unclear about where the rope is made. | Is a direct manufacturer with their own factory. |

| Hesitates about third-party inspection. | Welcomes third-party inspectors like BV or ABS. |

| Has no experience in your industry. | Has a proven track record with clients in oil and gas. |

Beyond the Rope: Support and Customization

A good supplier is a partner. They should have the technical knowledge to help you select the exact right rope for your equipment and environment. They should be able to answer your questions about construction, standards, and maintenance.

They should also be flexible. Maybe you need a specific length, a special end fitting, or your company logo printed on the reel. A good manufacturing partner can offer these specialized assemblies and customizations. Clear communication is key. You should have a direct contact, like my email info@wireropes.net, to get the support you need.

Conclusion

Choosing the right wire rope means understanding the environment, matching the rope to the job, verifying quality with certificates, and picking a trustworthy supplier. This ensures safety and performance.