Cutting braided stainless steel cable can be tricky. Are you struggling with frayed ends or a messy cut? Many people face this challenge when working with strong cables.

The best way to cut braided stainless steel cable cleanly is by using sharp, specialized tools like cable cutters or angle grinders, often combined with pre-wrapping the cut area. This prevents fraying and ensures a neat finish.

A while ago, I was working on a project that needed precise cuts for our specialized assemblies. I remember thinking, “There must be a better way to do this without all the fuss.” That experience got me thinking about the best methods.

How to choose the right cutting tool?

Choosing the right tool is key for a good cut. What tools can you use for braided stainless steel cable? It depends on the cable’s thickness and your desired finish.

You need tools designed for cutting metal or strong ropes. For thinner cables, a good cable cutter works best. For thicker cables, an angle grinder is often needed. Using the right tool prevents common problems like fraying.

When I started out, I used whatever I had. It was a disaster. The cuts were rough, and the cables frayed badly. Over time, I learned that investing in proper tools saves a lot of headaches and ensures our wire ropes look professional, just like the high-quality product they are.

Using the wrong tool can damage the cable. It can also be very unsafe. Here’s a look at common tools and their uses:

Cable Cutters

- Use: Suitable for thinner braided stainless steel cables.

- Feature: They have sharp blades that cut through the cable without crushing it.

- Pros: Clean, fast cuts, portable.

- Cons: Cannot be used for very thick cables.

| Cable Diameter Range | Recommended Tool | Pros | Cons |

|---|---|---|---|

| < 1/4 inch | Cable Cutters | Portable, Fast | Only for small diameters |

| 1/4-1/2 inch | Large Cable Cutters | Better cutting force | Requires more effort |

Angle Grinders

- Use: Suitable for thicker or high-strength braided stainless steel cables.

- Feature: Uses a rotating abrasive disc to cut.

- Pros: Powerful cutting ability, can handle very hard materials.

- Cons: Creates sparks and heat, requires protective gear.

Bolt Cutters

- Use: Only for specific situations, not recommended for precise cuts.

- Feature: Primarily used for cutting bolts or rebar.

- Pros: High cutting force.

- Cons: Can crush or damage the cable, resulting in an uneven cut.

For our high tensile strength wire rope, we often lean on robust methods. This ensures the integrity of the high breaking load characteristic of our products.

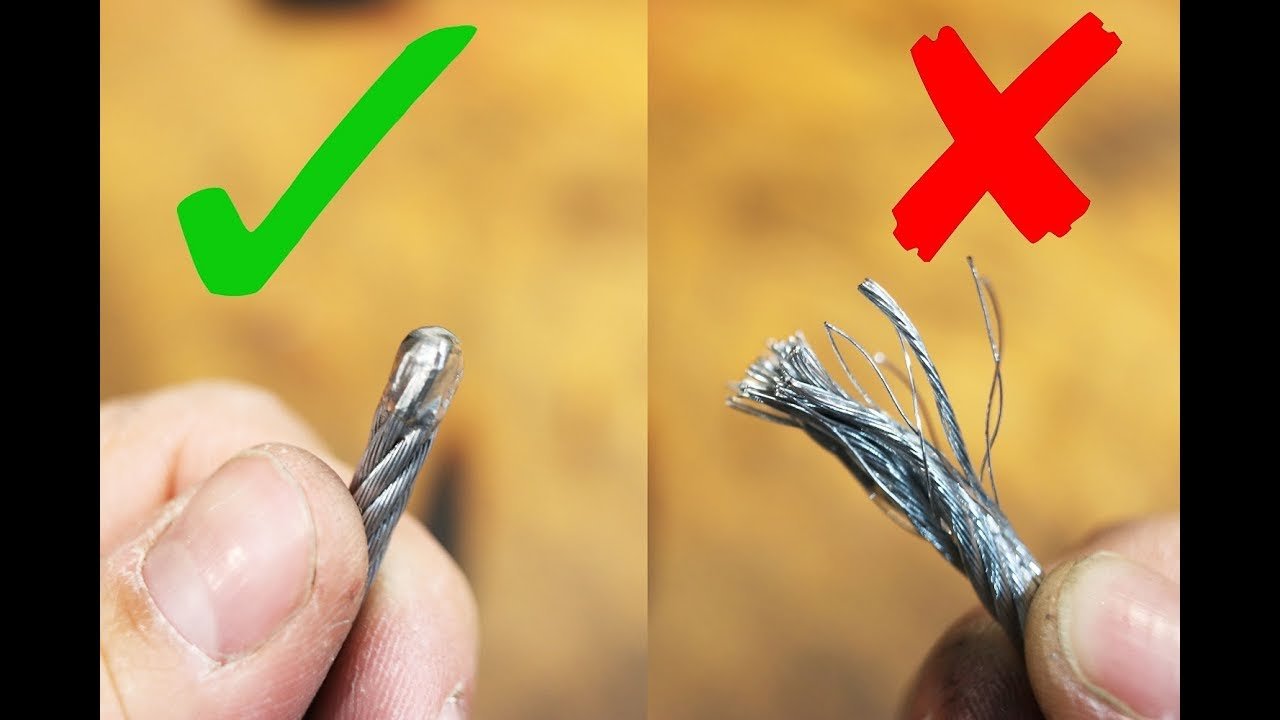

How to prevent the cut end from unraveling?

A common problem after cutting is fraying. How can you prevent the braided strands from unraveling after a cut? Preventing fraying is crucial for both function and appearance.

To prevent fraying, you should wrap the area where you plan to cut tightly with electrical tape or masking tape before making the cut. You can also solder the ends for a more permanent solution.

Imagine you’re trying to install an elevator wire rope, and the ends are all frayed. It just doesn’t look professional. More importantly, it can compromise the cable’s performance. When we prepare our mining wire rope for shipment, we ensure every end is perfect. It’s part of our commitment to quality.

Tape Wrapping Method

- Operation: Wrap several layers of strong tape around the cable on both sides of the cut point.

- Function: This holds the strands in place, preventing them from unraveling during the cut.

- Pros: Simple, low cost, suitable for most situations.

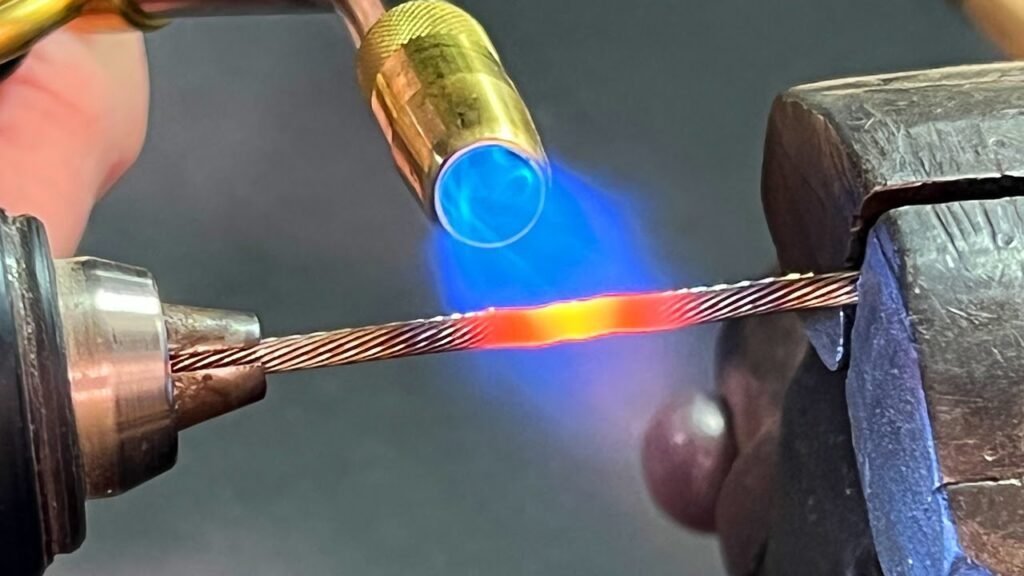

Soldering/Brazing

- Operation: After cutting, dip the cable end into solder or braze it with a flame.

- Function: This permanently solidifies the end.

- Pros: The most secure method to prevent unraveling.

- Cons: Requires specific equipment and skills.

Heat Shrink Tubing

- Operation: Slide heat shrink tubing over the cut cable end, then heat it with a heat gun to make it shrink.

- Function: Provides a protective layer and prevents unraveling.

- Pros: Clean, neat, offers extra protection.

These methods ensure that our products, whether it’s galvanized wire rope or marine wire rope, maintain their high quality from end to end.

What are the safety precautions when cutting stainless steel cable?

Safety is always first. What are the key safety precautions to take when cutting stainless steel cable? Working with metal cables can be dangerous if you don’t follow safety guidelines.

Always wear safety glasses, gloves, and protective clothing. Make sure your cutting area is clear and stable. Use the right tools and handle them with care. This protects you from injuries.

I’ve seen firsthand how important safety is. On our factory floor, where we produce tons of wire ropes, every single step is about safety. We deal with high tensile strength products. A moment of carelessness can lead to serious injury. It’s why we emphasize safety training for all our team members.

Personal Protective Equipment (PPE)

- Safety Glasses: Must be worn to protect eyes from flying debris and sparks.

- Gloves: Thick gloves protect hands from cuts and abrasions.

- Protective Clothing: Long-sleeved shirts and pants protect skin.

Work Area Safety

- Secure Workbench: Ensure the cable you are cutting is secured on a stable workbench.

- Clear Clutter: Keep your cutting area clean and free of obstacles.

- Ventilation: Ensure good ventilation if using an angle grinder, as it produces fumes.

Tool Handling

- Follow Instructions: Carefully read and follow the tool manufacturer’s instructions.

- Inspect Tools: Check tools for good condition before each use.

- Unplug: Unplug power tools when not in use.

Our factory in China follows strict safety protocols. We believe in delivering high-quality products like our stainless steel wire rope, and that starts with safe production practices. Our compliance with standards like EN12385-4 extends to our safety protocols too.

Conclusion

Cutting braided stainless steel cables requires the right tools and techniques. Remember to prioritize safety and prepare the cable properly to prevent fraying.