Are you tired of frequent breakdowns and costly downtime? Many businesses face these challenges, impacting productivity and profitability. We understand how frustrating this can be, especially when dealing with critical lifting operations.

Having high-quality crane ropes is crucial for ensuring the safety, efficiency, and longevity of your lifting equipment. It directly impacts operational reliability and reduces the risk of accidents.

Imagine the stress of a critical lift failing. It’s a scenario no operator wants to face. But what if I told you a simple change in your wire rope could prevent such nightmares and boost your business?

What Differentiates Aulone’s High-Quality Crane Ropes from the Rest?

Are you looking for crane ropes that truly perform? Understanding the key factors that set quality ropes apart is vital for informed purchasing decisions.

Our crane ropes are manufactured with superior materials and advanced technology, ensuring high tensile strength and exceptional breaking load, compliant with EN12385-4 standards.

Material Selection and Manufacturing Process

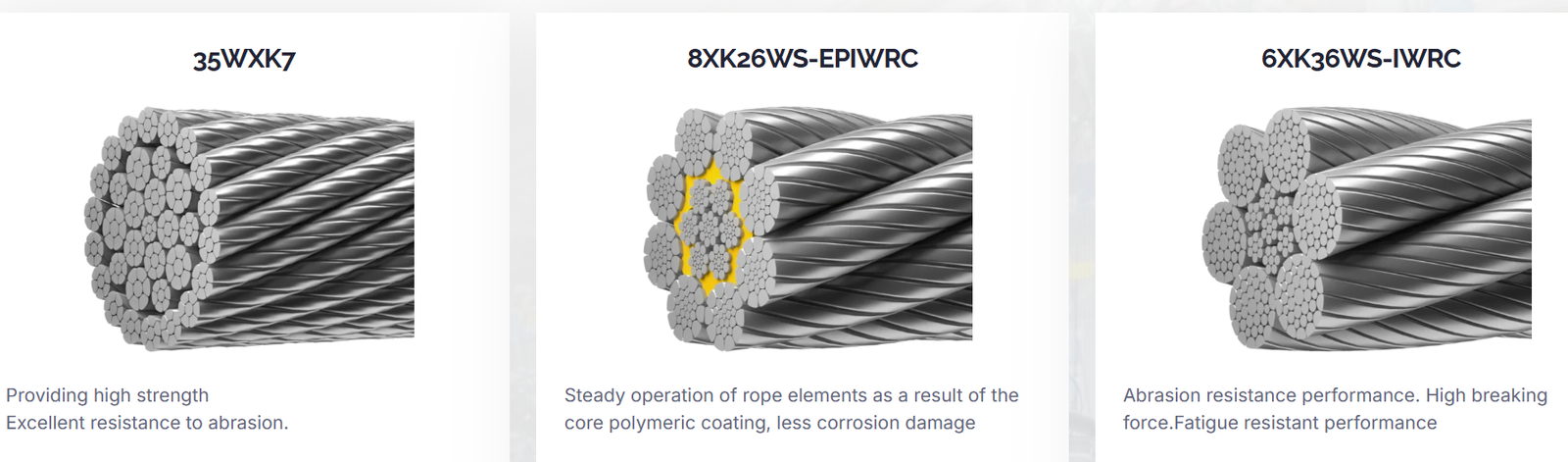

At Aulone, we start with the best raw materials. Our selection process is meticulous, ensuring only the highest grade steel is used. This is then processed through our four advanced production lines. Each line is calibrated for precision, guaranteeing consistent quality. For specialized applications, we offer ropes like 35W x K7 non-rotating steel wire rope, which is ideally suited for hoist applications due to its minimal rotation under load. We also provide construction types such as 8XK26WS-IWRC and 6XK36WS-IWRC, commonly used for luffing wire ropes where flexibility and strength are paramount.

Furthermore, we specialize in advanced manufacturing techniques. We offer plastic-impregnated wire ropes, where a layer of polymer is inserted into the core. This significantly reduces internal friction, enhances lubrication, and protects against corrosion and crushing, greatly extending the rope’s service life. We also provide compacted wire ropes. This process involves mechanically pressing the outer strands of the wire rope. Compacting increases the metallic cross-sectional area, resulting in higher breaking strength and improved resistance to abrasion and crushing compared to conventional ropes.

We also offer galvanized wire ropes, providing a crucial layer of protection against rust and environmental degradation, making them ideal for marine or humid conditions.

Compliance and Certifications

We know that specifications and certifications are non-negotiable for many of our clients. That’s why our crane ropes are designed to meet EN12385-4 standards. If your project requires it, we can provide BV, CE, RMRS, DNV, and ABS certifications. This commitment to international standards assures you of our product’s reliability and safety.

Customization and Branding

Your brand deserves to be recognized. We offer customizable logo options on our wire ropes. This not only reinforces your brand identity but also helps in asset management. It’s a small touch that signifies our dedication to meeting your specific needs.

Durability Features

Our ropes are built to last. Features like plastic impregnation protect the core, reducing internal wear, while galvanization provides a strong defense against rust and environmental degradation. These features are critical for extending the service life of the rope, especially in harsh working conditions typical of mining or heavy industrial lifting.

How Do Aulone’s Crane Ropes Enhance Operational Efficiency and Safety?

Are you seeking to minimize operational disruptions and elevate safety standards? Investing in superior crane ropes can significantly contribute to both.

Our high-quality crane ropes are engineered for maximum performance, leading to fewer failures, reduced maintenance, and a safer working environment for your personnel.

Reducing Downtime

Downtime is a major cost for any operation. Inferior ropes are prone to premature wear and breakage, leading to unexpected stoppages. Our ropes’ high tensile strength and superior construction mean they withstand heavier loads and last longer. This translates directly into fewer replacements and less time spent on maintenance, keeping your machinery running smoothly and productively.

Ensuring Operator and Site Safety

Safety is paramount in any lifting operation. A snapped wire rope can cause catastrophic damage and severe injuries. The high breaking load capacity of our ropes is rigorously tested to ensure it exceeds industry standards. This provides a vital safety margin, protecting not only your equipment and cargo but most importantly, your people. We are committed to providing the most reliable components for your critical tasks.

Optimizing Lifting Capacity

With our crane ropes, you can confidently lift heavier loads. The high tensile strength means that our ropes can handle greater stress without deforming or breaking. This allows you to maximize the efficiency of your cranes, potentially reducing the number of lifts required for a job and speeding up project completion. This is especially beneficial for industries like mining and construction where heavy-duty lifting is routine.

Longevity and Cost-Effectiveness

While the initial investment in high-quality crane rope might seem higher, the long-term savings are substantial. Our ropes’ enhanced durability means a longer service life, reducing the frequency of replacements. This lowers your overall procurement costs over time and minimizes the labor associated with rope changes. It’s an investment in reliability that pays dividends.

Dive Deeper: Critical Factors Beyond Tensile Strength

While tensile strength is a key indicator, a truly high-quality crane rope involves a holistic approach to its design and manufacture. We consider several factors to ensure optimal performance:

| Feature | Description | Impact on Performance |

|---|---|---|

| Core Material | Often fiber (e.g., IWF) or independent wire rope core (IWRC). | Affects flexibility, crush resistance, and overall strength. |

| Wire Construction | The arrangement and twist of individual wires within the rope strands. | Influences flexibility, abrasion resistance, and fatigue life. |

| Lubrication | Internal lubrication to reduce friction between wires and strands. | Crucial for preventing internal wear and corrosion, extending life. |

| Galvanization | A protective zinc coating applied to wires or strands. | Provides corrosion resistance, vital in marine or humid environments. |

| Surface Finish | The smoothness or texture of the outer wires. | Can affect snagging and resistance to surface abrasion. |

| Manufacturing Method | Techniques like preforming wire strands before spiraling them into rope. | Ensures the rope retains its shape and is easier to handle. |

Understanding these elements helps appreciate why selecting a rope from a reputable manufacturer like Aulone is crucial. For instance, our plastic-impregnated ropes offer superior internal lubrication, a factor often overlooked but critical for preventing internal strand breakage under high load and constant flexing. Our compacted ropes, whether galvanized or not, provide increased strength and smooth surfaces that improve spooling and reduce wear. This attention to detail, combined with our precise manufacturing of constructions like 8K x 26WS-IWRC and 6K x 36WS-IWRC for luffing applications, and 35W x K7 non-rotating ropes for winches, ensures you receive a product that meets the highest demands.

Conclusion

Invest in high-quality crane ropes for reliability, safety, and efficiency.