Does your drilling rig suffer from unexpected downtime? The constant stress on your equipment can lead to costly failures, and your drilling line is often the first point of weakness.

A drilling line is a specialized wire rope used in the hoisting system of a drilling rig. It raises and lowers the traveling block and drill string. Its primary role is to handle immense dynamic loads safely and repeatedly.

I remember visiting a rig where they used a slightly underspecified rope to save a little money. This decision led to a premature failure that shut down their operations for days, costing them far more than they initially saved. Let’s make sure that doesn’t happen to you.

What is a Drilling Line and Why is It So Critical?

Your drilling line seems like just a simple steel cable. But it is the most important component in your rig’s hoisting system. Understanding its function is the first step toward safety and efficiency.

The drilling line is the workhorse that connects the drawworks, crown block, and traveling block. It spools on and off a drum to lift and lower hundreds of tons of equipment into the wellbore.

Dive Deeper: The Heart of the Hoisting System

The entire weight of the drill string, casing, and other tools hangs from the drilling line. It runs from the drawworks drum up to the crown block at the top of the derrick. Then, it is reeved (or threaded) multiple times between the crown block and the traveling block. This reeving creates a pulley system. This system gives the rig the mechanical advantage needed to lift extremely heavy loads.

The drilling line is always in motion. It bends constantly as it passes over sheaves and spools onto the drum. It also experiences vibration and shock loads. This combination of tension and bending is what causes fatigue and wear over time. This is why a high-quality, correctly specified drilling line isn’t just a recommendation; it’s a necessity for a safe and productive drilling operation.

How Do You Choose the Right Specifications for a Drilling Line?

Selecting the wrong drilling line is a big risk. You might face safety hazards or reduced operational life. So, knowing the key specifications is crucial before you make a purchase.

To choose the correct drilling line, you must focus on four key specifications: diameter, grade, construction, and core. These factors together determine the rope’s strength, flexibility, and resistance to wear and crushing.

Breaking Down the Specs

Let’s look at each of these specifications more closely. I always tell my clients that getting these details right from the start saves a lot of trouble later.

H3: Diameter and Grade – The Foundation of Strength

The diameter is determined by your rig’s design. You must use the size specified by the equipment manufacturer. Using a wrong size can cause improper spooling on the drum and damage to both the rope and the sheaves.

The grade of the steel tells you the rope’s nominal strength. For drilling lines, the most common grades are defined by the American Petroleum Institute (API).

| Grade | Name | Description |

|---|---|---|

| EIPS | Extra Improved Plow Steel | A common choice offering high strength. |

| EEIPS | Extra Extra Improved Plow Steel | About 10% stronger than EIPS. It is often used for deeper drilling and heavier loads. |

Choosing a higher grade like EEIPS can sometimes allow for a smaller rope diameter for the same strength, but you must check your equipment’s compatibility.

Construction – Balancing Flexibility and Durability

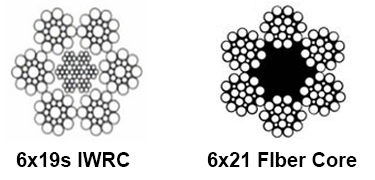

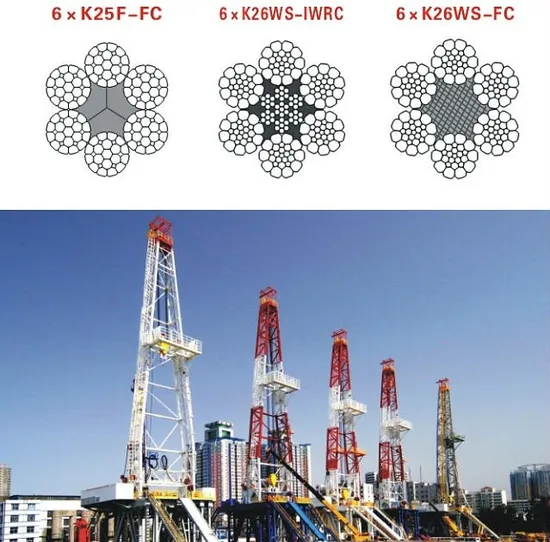

Construction refers to how the individual wires are laid to form strands, and how those strands are laid around the core. For drilling lines, a 6x19 or 6x21 classification is standard. This means there are 6 strands wrapped around a core.

| Construction | Characteristics | Best For |

|---|---|---|

| 6×19 Seale | Larger outer wires | High resistance to abrasion and crushing. |

| 6×19 Filler | Good balance of flexibility and wear resistance. | General-purpose drilling operations. |

| 6×21 Filler | More flexible than 6×19 | Good for applications with smaller sheaves or drums. |

The choice here depends on your rig’s specific setup and the type of wear you see most often.

The Core – IWRC is Standard

The core is the center of the wire rope that supports the outer strands.

- FC (Fiber Core): Provides good flexibility but can be crushed under high loads. Not recommended for drilling lines.

- IWRC (Independent Wire Rope Core): This is a small wire rope in itself, acting as the core. It provides excellent crush resistance and strength. It is the standard for almost all drilling line applications. You should always insist on an IWRC for your drilling line.

Why is a Regular Cut-Off Program So Important?

You bought a high-quality drilling line. That’s great. But your work is not done. You must have a plan to manage wear and tear to ensure a long, safe service life.

A cut-off program is a planned maintenance procedure where you systematically cut and remove the most worn sections of the drilling line. This practice extends the rope’s total service life and prevents unexpected failures.

Dive Deeper: Managing Inevitable Wear

I have seen many companies replace their entire drilling line too early. They do this because they don’t have a proper cut-off program. A good program saves you money and, more importantly, improves safety.

Where Does the Wear Happen?

The wear on a drilling line is not uniform. It concentrates at specific points.

- The Dead-Line End: The section of rope attached to the anchor is stationary and experiences high tension.

- Crossover Points on the Drum: As the rope winds onto the drawworks drum, it crosses over the layer below. These crossover points create severe crushing and abrasion.

- Sheave Contact Points: The sections of rope that are repeatedly bent over the crown and traveling block sheaves experience internal and external fatigue.

The goal of a cut-off program is to remove these heavily worn sections before they can fail.

The Slip-and-Cut Goal

The procedure is based on a “slip-and-cut” method. You calculate a specific length of rope to “slip” through the system. This moves the high-wear points to new positions. Then, you cut this length from the drum end of the rope. This process is based on the amount of work the rope has done, often measured in ton-miles. By regularly moving and removing the most damaged parts, you distribute the wear over the entire length of the rope.

Benefits of a Good Program

A well-managed cut-off practice isn’t just about safety. It’s good business.

| Benefit | Description |

|---|---|

| Increased Safety | Removes weakened sections before they can fail unexpectedly. |

| Longer Rope Life | You use more of the rope’s total length, maximizing your investment. |

| Reduced Downtime | Planned maintenance is always better than an unplanned shutdown. |

| Lower Costs | You buy new drilling lines less frequently. |

What Should I Look for in a Drilling Line Supplier?

You now understand the technical side of drilling lines. The final step is choosing the right partner to supply them. This decision is just as critical as your technical specifications.

You should look for a supplier with proven manufacturing experience, strong quality control, adherence to API 9A standards, and verifiable third-party certifications. Price is important, but reliability and trust are essential.

Choosing a Partner, Not Just a Product

Over my years in this business, I’ve learned that the best supplier relationships are partnerships. Your supplier should be invested in your success.

Quality Control and Traceability

Never buy a critical item like a drilling line based on price alone. Ask a potential supplier about their quality control process.

- Do they provide a mill certificate with every rope? This document should show the results of destructive tests, confirming the actual breaking strength.

- Can they trace the product back to the raw materials used? Full traceability is a sign of a mature and serious manufacturing process.

- We have four production lines in our factory. This capacity allows us to maintain strict quality checks at every stage without rushing the process.

The Power of Certification

Certifications are not just papers. They are proof that a third party has inspected and approved a manufacturer’s product and process. For drilling lines, the API 9A monogram is the gold standard.

| Certification | What It Means | Why It Matters |

|---|---|---|

| API 9A | Conformance to the American Petroleum Institute’s standard for wire rope. | Ensures the product is suitable for oil and gas drilling applications. |

| ABS, DNV, etc. | Approval by maritime classification societies. | Shows a high level of quality control accepted in the demanding marine and offshore industries. |

| ISO 9001 | Certification of the manufacturer’s quality management system. | Indicates a commitment to consistent processes and continuous improvement. |

A few years ago, we helped a client in Australia secure a major drilling contract. Their competitor had a slightly lower price, but their rope was not API certified. We provided our client with a fully certified rope and all the documentation. That certified quality gave the end-user the confidence to award the contract to our client.

Look Beyond the Price Tag

Your purchasing decision should be based on total value, not just the initial cost. A reliable supplier offers more. They provide technical support, understand your operational needs and help you with cut-off program calculations. They hold stock and provide reliable delivery times, which is critical for planning. A good partner helps you reduce downtime and improve safety, offering a much better return on investment in the long run.

Conclusion

Choosing and managing your drilling line correctly is a key part of running a safe and efficient operation. Focus on quality, specifications, and a supplier you can trust.