Are you struggling with heavy lifting? Do you need a safe and reliable solution? A 4-leg chain sling could be your answer.

A 4-leg chain sling lifts heavy loads safely. It has four chains attached to a master link. This design spreads the weight evenly.

I understand the challenges of heavy lifting. My experience in the wire rope industry has shown me the need for dependable tools. Let’s explore how these slings work.

How does a 4-leg chain sling enhance lifting safety?

Does lifting safety worry you? A 4-leg chain sling improves safety. It offers stability and strength.

A 4-leg chain sling enhances safety by distributing the load. This reduces stress on individual chains. It provides better balance for awkward or heavy items.

When I talk to clients, safety is always a top concern. We develop products that meet high safety standards. A 4-leg chain sling is one such product. It is designed to maximize safety during lifting operations.

Dive Deeper: The Core of Safe Lifting

A 4-leg chain sling is a crucial tool for safe lifting. It offers significant advantages over other types of slings.

The design is simple yet effective. Four separate chains connect to a central master link. This design helps in several ways:

- Load Distribution:

- Each leg shares the load.

- This reduces stress on any single point.

- It minimizes the risk of failure.

- Stability:

- The four points of contact provide excellent stability.

- This prevents the load from swinging.

- It helps in controlling the load precisely.

- Versatility:

- It can lift loads with uneven weight.

- It is suitable for different shapes and sizes.

- It adapts to various lifting scenarios.

Consider a large, irregularly shaped object. A single-leg sling would struggle to balance it. A 4-leg sling cradles the object. This keeps it stable during the lift.

For proper use, always check the sling’s Working Load Limit (WLL). This limit tells you the maximum weight the sling can safely lift. Overloading a sling is dangerous. It can lead to failure.

We ensure our products meet strict quality standards. This includes compliance with EN12385-4. This standard sets rules for wire rope safety. We also offer certifications like BV & CE, RMRS, DNV, and ABS. These certificates confirm product quality and safety.

What are the main components of a 4-leg chain sling?

Are you curious about what makes up these slings? Understanding the parts helps you use them better.

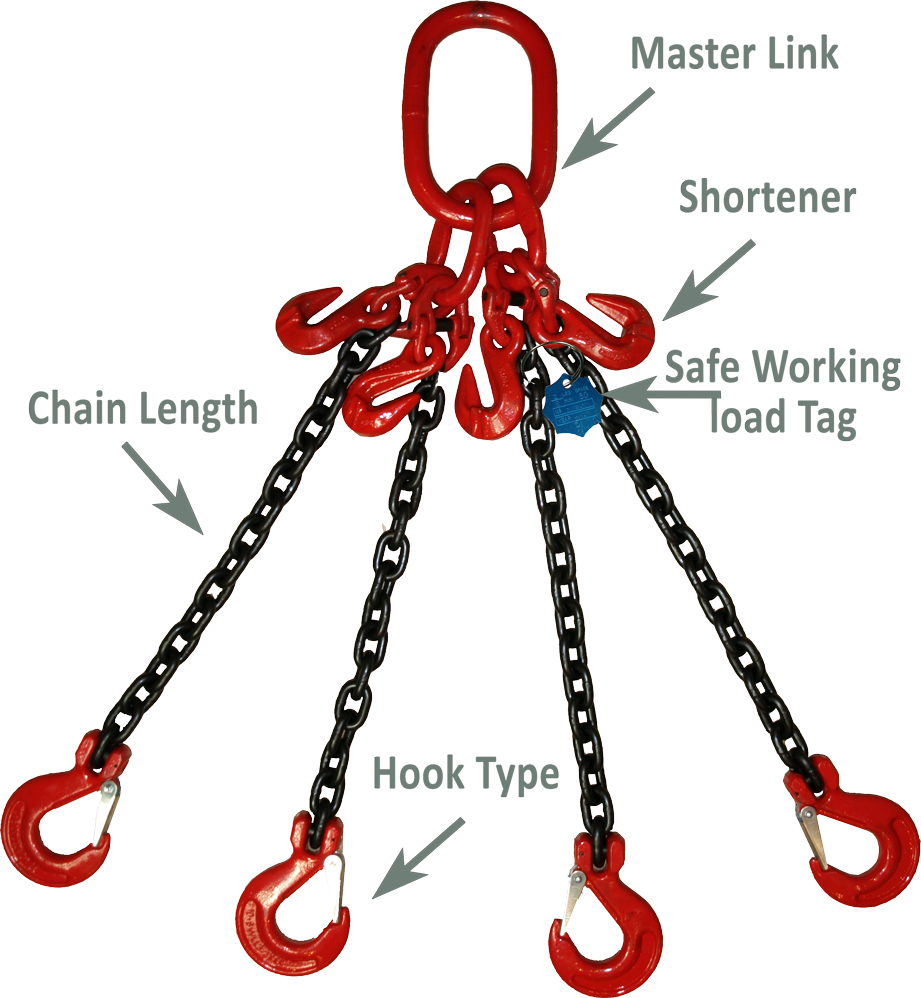

A 4-leg chain sling has a master link, four chain legs, and end fittings. The master link connects to the crane hook. The chain legs attach to the load. End fittings secure the load.

Our factory focuses on high-quality components. We use strong materials for every part. This ensures durability and performance.

Dive Deeper: Anatomy of a Chain Sling

Each part of a 4-leg chain sling plays a vital role. Knowing each part helps with proper setup and use.

The main components are:

- Master Link: This is the top ring. It connects the sling to the crane hook. It must be strong enough to hold the entire load.

- Chain Legs: There are four of these. They extend from the master link to the load. The chains are made of high-grade alloy steel. They are designed for high tensile strength. This means they can handle heavy pulling forces.

- End Fittings: These attach to the load itself. Common types include:

| End Fitting Type | Description | Common Use Cases |

|---|---|---|

| Sling Hooks | Standard hooks for general lifting. | Lifting objects with attachment points. |

| Grab Hooks | Allows chain shortening for customized lifts. | Adjusting sling length for different loads. |

| Foundry Hooks | Larger throat opening, good for larger parts. | Lifting large castings or bulky items. |

| Self-Locking Hooks | Automatically lock once tension is applied. | Enhanced safety, preventing accidental disengagement. |

Each component is crucial. The quality of each part affects the sling’s overall strength. We use rigorous testing methods. This ensures high breaking loads. Our products are made to last. They can withstand tough conditions.

For example, when we ship products to countries like Australia, they have strict quality control. Our slings are built to meet these high demands. This means durable chains and reliable fittings.

Where are 4-leg chain slings commonly used?

Do you wonder where these slings fit in? They are used in many industries.

4-leg chain slings are widely used in construction, manufacturing, and mining. They lift heavy, awkward, or multiple loads. They are essential for demanding industrial tasks.

I have seen our slings used globally. From Singapore to Canada, they help move vital materials. Their versatility makes them a popular choice.

Dive Deeper: Industries Relying on Chain Slings

The applications of 4-leg chain slings are diverse. They are found in environments where heavy and safe lifting is critical.

Here are some key sectors and their uses:

- Construction:

- Lifting structural beams.

- Moving large concrete blocks.

- Positioning heavy machinery.

- They are especially useful in multi-story building projects. They can lift materials to different levels.

- Manufacturing:

- Handling heavy machinery parts.

- Moving dies and molds.

- Transferring raw materials in factories.

- This includes automotive production. It aids in lifting engine blocks.

- Mining:

- Lifting heavy mining equipment.

- Moving excavated materials.

- Supporting underground construction.

- These slings are built tough. They withstand the harsh mining environment.

- Shipbuilding and Marine:

- Lifting boat sections.

- Moving enormous ship components.

- Loading and unloading cargo from ships.

- Our marine wire ropes are often used here. They work well with chain slings.

- Energy Sector (Oil & Gas, Wind Power):

- Lifting components for oil rigs.

- Installing massive wind turbine blades.

- Transporting heavy power generation equipment.

- Our galvanized wire ropes are popular in these corrosive settings.

These slings are ideal for loads that need stability. They handle objects that are large or have an uneven center of gravity. For example, a large engine block can be lifted evenly. This prevents tilting during the lift. Our custom solutions allow clients to choose specifications such as custom logos. This helps them meet specific project needs. We also offer plastic impregnated and galvanized options. These resist corrosion and wear even more.

Conclusion

A 4-leg chain sling offers safe and stable heavy lifting. It has a master link, four chains, and end fittings. It is crucial in many industries like construction and mining.