Are you facing challenges with wire rope twisting and tangling? Does your current rope cause safety and efficiency issues? Non-rotating wire ropes can solve these problems.

Non-rotating wire ropes are designed to resist rotation under load. They prevent twisting and ensure stable lifting operations. This design improves safety and extends rope life.

Let me tell you about a time a client faced similar issues. They had constant problems with standard ropes. They needed a better solution. (Insert personal story here)

Why do non-rotating wire ropes resist rotation?

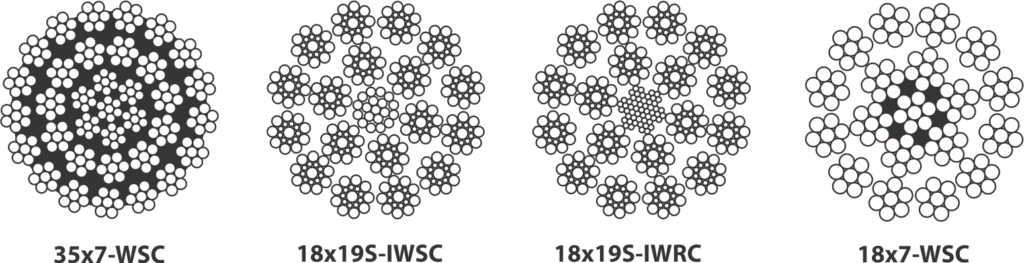

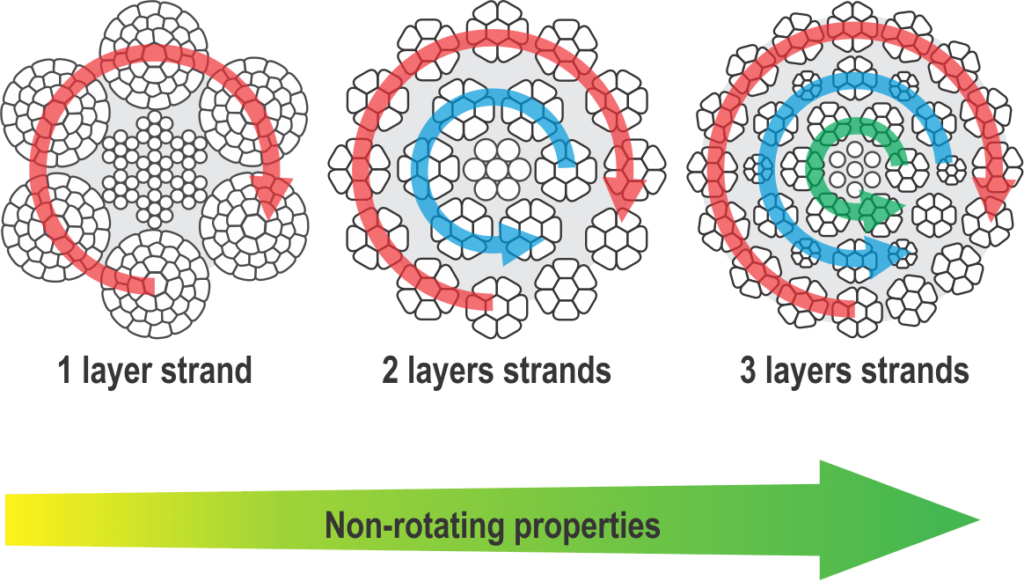

Non-rotating wire ropes resist rotation because of their unique construction. They have inner and outer layers of strands laid in opposite directions. This counter-lay design neutralizes torque.

This special construction balances the rotational forces within the rope. When one layer tries to twist, the opposing layer pulls back. This keeps the rope stable and straight.

How the Construction Works

Let’s look closer at how this construction makes non-rotating ropes so effective.

Think of it like two springs pushing against each other.

- Inner Strands: These are laid in one direction, for example, right-hand lay.

- Outer Strands: These are laid in the opposite direction, for example, left-hand lay.

When a load is applied, each layer wants to twist. But because they are laid oppositely, their twisting forces cancel each other out. This means the rope does not rotate.

This design is crucial for safety. It prevents loads from spinning. It also stops the rope from unraveling. This makes it ideal for many uses.

Where are non-rotating wire ropes commonly used?

Non-rotating wire ropes are essential in applications where twisting is unacceptable. They are used in places needing high stability and safety. This includes many heavy-duty operations.

They are commonly used in crane hoisting, especially for single-fall lines. You will also find them in deep lifting operations, like those in mining or construction. They are crucial for passenger lifts as well.

I have seen countless projects where standard ropes caused problems. A non-rotating rope was often the only way to ensure safety.

Specific Applications

Let’s explore some key areas where these ropes shine.

Cranes and Hoists

Many cranes use non-rotating ropes for their main hoist lines. This is especially true for mobile cranes or tower cranes. These cranes often lift loads with a single line. Without a non-rotating rope, the load would spin uncontrollably. This is very dangerous.

Imagine a heavy component being lifted high. If it starts to spin, it can hit structures or injure workers. Non-rotating ropes prevent this.

Mining Operations

In mining, very deep shafts are common. Ropes are used to lift materials or personnel. Long falls mean any twist can become severe. Non-rotating ropes ensure a straight and stable lift. They are critical for miner safety and efficient material handling.

Elevator Systems

Elevator wire ropes are a prime example. The safety of passengers depends on the ropes not twisting. While many elevator ropes are complex, some designs use non-rotating principles to ensure smooth, stable vertical movement. This is a critical safety feature.

Marine and Offshore

Offshore platforms and marine vessels also use these ropes. They are often used for subsea lifting or in winches. Stability is key in a dynamic marine environment. Non-rotating ropes help maintain control.

What advantages do non-rotating wire ropes offer?

Non-rotating wire ropes offer many advantages over standard ropes. These benefits lead to better performance, safety, and cost savings. They are designed for demanding work.

Their main advantages include enhanced safety by preventing load rotation. They also provide increased stability during lifting operations. Furthermore, they can extend the service life of the rope and associated equipment.

One time, a client switched to Aulone’s non-rotating ropes. They saw an immediate drop in operational issues. This saved them a lot of money and time.

The Benefits Explained

Let’s break down these advantages.

Enhanced Safety

This is perhaps the most important benefit. By preventing load rotation, non-rotating ropes eliminate a major hazard. Worker safety improves drastically. Injuries from spinning loads are avoided. Damage to equipment or structures is reduced.

Increased Stability

When a load hangs straight, it is easier to control. Operators have better precision. This is vital in tight spaces or when placing delicate items. It also reduces dynamic loads on the crane structure.

Extended Rope Life

Twisting and untwisting under load cause stress on standard ropes. This leads to premature wear. Non-rotating ropes avoid this internal stress. They maintain their integrity longer. This means fewer rope changes and less downtime. It saves money over time.

Reduced Equipment Wear

When the rope does not twist, it puts less strain on other components. Sheaves, drums, and bearings last longer. This reduces maintenance costs for the entire lifting system.

Better Readability for Inspections

A rope that maintains its shape is easier to inspect. Damage or wear becomes more visible. This helps in early detection of problems. It allows for timely replacement, preventing failures.

How do non-rotating ropes impact operational costs and safety?

Non-rotating ropes can greatly impact operational costs and safety. They bring clear benefits across many industries. This is from a practical and financial standpoint.

They significantly reduce safety risks by preventing load rotation and improving stability. This leads to fewer accidents. In terms of cost, they lower maintenance needs and extend equipment life. This means less downtime and fewer replacements.

I always tell clients that investing in the right rope technology pays off. It’s not just about the initial cost; it’s about the bigger picture.

Cost and Safety Implications

Let’s look at the financial and safety aspects in more detail.

Safety Improvements

- Reduced Accidents: No twisting means loads won’t spin out of control. This lowers the chance of hitting workers or structures.

- Worker Confidence: Operators feel safer. This can improve morale and productivity.

- Compliance: Using the right rope ensures compliance with safety regulations. This avoids fines and legal issues.

Cost Reductions

- Less Downtime: If ropes last longer, machines run more. This increases output.

- Lower Maintenance: Parts that don’t twist violently last longer. This means less money spent on repairs.

- Reduced Replacements: You buy fewer ropes over time. This is a direct saving.

- Insurance Benefits: Some insurers might offer better rates for safer operations.

- Productivity Gains: Smooth operations without delays lead to faster project completion. This directly affects the bottom line.

Using non-rotating wire ropes is a smart decision for any business that relies on lifting. It brings both immediate and long-term benefits. It moves a business towards safer and more efficient operations. This is why Aulone focuses on providing high-quality solutions like these.

Conclusion

Non-rotating wire ropes are crucial for safe and efficient lifting. They prevent twisting, enhance stability, and cut operational costs. They are a smart investment.