Does lifting heavy things feel complicated? Are you worried about safety and damage? Many people face these problems when moving loads.

Rigging is setting up equipment to lift and move loads. Slinging is connecting the load to the lifting device. Both ensure safe and efficient movement.

I remember once working on a tough job. The client needed a huge machine moved. If we did it wrong, it could be very dangerous.

What is the difference between rigging and slinging?

Rigging and slinging are terms often used together. But they are not the same. It is important to know their specific roles.

Rigging involves planning and preparing the lifting system. Slinging is the actual attachment of slings to the load.

Dive Deeper: The Big Picture vs. The Direct Connection

Think about building a house. Rigging is like drawing the blueprints and gathering all the tools. Slinging is like actually laying the bricks. One is about the overall plan and setup. The other is about the direct action.

- Rigging: More Than Just Ropes Rigging includes picking the right crane or hoist. It means checking the ground for stability. It also involves choosing the correct shackles and hooks. Riggers plan the lift path carefully. They look at the load’s weight and shape. They decide how to balance it. This keeps people safe. It also protects the equipment.

- Key Rigging Steps:

- Load Assessment: Find out the load’s weight, dimensions, and center of gravity.

- Equipment Selection: Choose appropriate cranes, hoists, and rigging hardware.

- Lift Plan Creation: Develop a detailed plan for the lift, including safety procedures.

- Site Preparation: Ensure the lift area is clear and safe for operations.

- Key Rigging Steps:

- Slinging: The Critical Link Slingers work directly with the load. They attach the slings. They make sure the slings are correctly placed. This prevents slippage. It also stops damage. They check for twists. They ensure proper tension. A bad sling connection can cause big problems. It can lead to the load falling. This is very dangerous. Our products are designed for reliable slinging. They offer high tensile strength. They have high breaking loads. This provides safety.

- Important Slinging Aspects:

- Sling Inspection: Check slings for damage before each use.

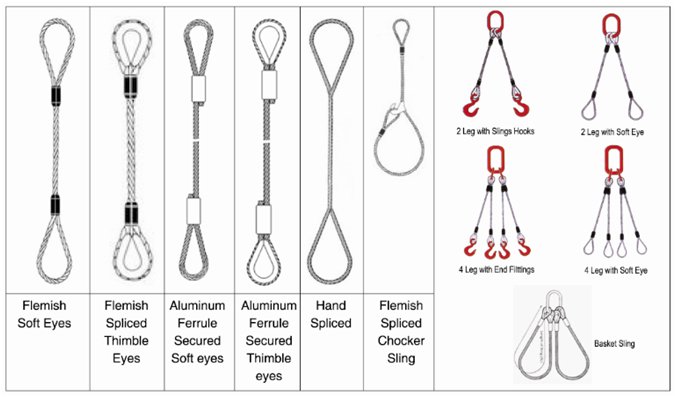

- Attachment Methods: Use correct hitches (e.g., basket, choker, vertical).

- Load securement: Ensure the load is stable and balanced in the sling.

- Communication: Work closely with the rigger and crane operator.

- Important Slinging Aspects:

What are the roles of riggers and slingers?

Riggers and slingers have distinct jobs. Both roles are vital for safe lifting. They work together closely.

Riggers plan and supervise the lift. Slingers attach and detach the loads safely.

Dive Deeper: Teamwork Makes the Dream Work

Imagine a complex surgery. The lead surgeon plans everything. The assisting nurses handle the instruments. Both are skilled. Both are necessary. It’s similar for rigging and slinging.

- The Rigger: The Brains of the Operation The rigger is often the team leader. They understand physics and engineering. They make sure all equipment is rated for the load. They oversee safety checks. They communicate with the crane operator. They are often certified in their field. They know how to handle different types of wire rope. For example, our EN12385-4 compliant wire ropes are a perfect fit. They meet strict quality standards.

- Riggers’ Main Duties:

- Planning Lifts: Designing the safest and most efficient lifting sequence.

- Equipment Setup: Ensuring all rigging gear is correctly assembled and positioned.

- Safety Oversight: Monitoring the entire operation for hazards and compliance.

- Communication: Directing the crane operator and slinging team.

- Riggers’ Main Duties:

- The Slinger: The Hands-On Expert The slinger is often on the ground. They are close to the load. They use hand signals. They guide the crane operator. They need good judgment. They must be aware of their surroundings. They also need to know about different types of wire ropes. They might use specialized assemblies or galvanized wires. Our large range of products helps here. They are used in various lifting scenarios.

- Slingers’ Main Responsibilities:

- Attaching Slings: Securely connecting the load to the lifting apparatus.

- Signaling: Giving clear, standardized signals to the crane operator.

- Load Monitoring: Watching the load during the lift for any shifts or issues.

- Hazard Awareness: Identifying and communicating potential dangers on the ground.

- Slingers’ Main Responsibilities:

What type of certifications do riggers and slingers need?

Certifications are very important. They show a worker has the right skills. They also prove they know safety rules. This protects everyone on the job site.

Riggers and slingers need specific certifications. These prove their competence and adherence to safety standards.

Dive Deeper: Ensuring Competence and Compliance

My factory follows strict rules. We know certifications matter. They reduce risks. They build trust. For example, we offer BV & CE, RMRS, DNV, and ABS certificates. This shows our commitment to quality.

- Rigging Certifications: Riggers often need more extensive training. They handle complex calculations. They manage larger projects. Certifications can come from various bodies. These include NCCER or OSHA. They cover topics like load dynamics. They also cover safety regulations. Sometimes, specialized training is needed. This might be for specific cranes or tasks.

- Common Rigger Certifications:

- NCCER Rigger Certification: Recognizes proficiency in rigging principles and practices.

- OSHA 10 or 30 (Construction/General Industry): Basic safety training for worksites.

- Specialized Crane Rigging Certifications: For particular types of cranes or advanced lifts.

- Common Rigger Certifications:

- Slinging Certifications: Slingers also need proper training. Their certifications focus on practical skills. They learn about different slings. They learn how to inspect them. They learn correct attachment methods. This ensures the load is stable. It also ensures it’s safe to lift.

- Common Slinger Certifications:

- NCCER Slinger Certification: Focuses on safe slinging techniques and equipment use.

- OSHA General Safety Training: Basic safety awareness relevant to lifting operations.

- In-House Training and Competency Assessments: Many companies provide their own specific slinging training.

- Common Slinger Certifications:

What common equipment do riggers and slingers use?

Riggers and slingers rely on specific tools. These tools help them do their jobs safely. Having the right equipment is key to a successful lift.

Riggers and slingers use various equipment. This includes wire ropes, shackles, hooks, and specialized lifting gear.

Dive Deeper: The Tools of the Trade

At Aulone, we make many of these critical items. We understand that quality truly matters. Our products support these vital tasks.

- Wire Ropes: Wire ropes are the backbone of many lifting operations. They come in different types. There are general purpose wire ropes. There are specialized wire ropes for cranes or elevators. We make wire ropes with high breaking loads. They are compliant with EN12385-4. You can even get them plastic impregnated or galvanized. This makes them last longer.

- Types of Wire Ropes:

- Crane Wire Ropes: Designed for heavy lifting in cranes.

- Elevator Wire Ropes: Specific for vertical transport.

- Mining Wire Ropes: Built for tough conditions in mines.

- Galvanized Wire Ropes: Coated for rust resistance, good for marine use.

- Types of Wire Ropes:

- Shackles and Hooks: These are connectors. Shackles link slings to loads or other rigging components. Hooks connect to lifting points. Both must be strong enough for the load. They also need to be inspected regularly.

- Common Connectors:

- Bow Shackles: Versatile, good for multi-directional pulls.

- D-Shackles: Ideal for in-line tension.

- Lifting Hooks: Available in various designs (e.g., eye hooks, clevis hooks).

- Common Connectors:

- Slings (Chain, Synthetic, Wire Rope): Slings are the actual connection between the load and the lifting device. Each type has its own strengths. Synthetic slings are lighter and don’t scratch loads. Chain slings are durable and adjustable. Wire rope slings are strong and common. We also make synthetic ropes (and of course, quality wire rope for slings!).

- Different Sling Materials:

- Wire Rope Slings: Strong, durable, widely used.

- Synthetic Slings: Flexible, lightweight, good for finished surfaces.

- Chain Slings: Adjustable, resistant to high temperatures, very strong.

- Different Sling Materials:

- Other Essential Equipment: There are many other tools. These include hoists, winches, and even spreaders. Each plays a role in safe and efficient lifting. Our specialized assemblies and wire products support these needs.

- Additional Tools:

- Hoists: Manual or powered devices for lifting.

- Winches: Used for pulling or tugging heavy loads.

- Spreader Bars: Distribute weight over a larger area to prevent load damage.

- Additional Tools:

Conclusion

Rigging and slinging are crucial for safe lifting operations. Understanding them prevents accidents and ensures efficiency. My company provides high-quality products to support these vital industries.