I see many crane teams struggle with rope failures, so I want to explain how choosing the right wire rope solves this problem quickly and reliably.

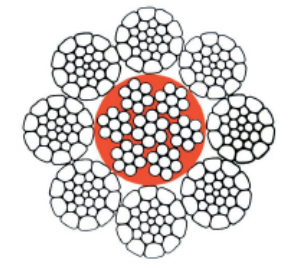

Luffing cranes need strong, flexible wire ropes for safe lifting. Hoist ropes: 35WXK7 or 15XK7. Luffing/pendant ropes: 8XK26WS-IWRC, 8XK26WS-EPIWRC, 6XK36WS-IWRC. Proper selection ensures high breaking load, bending fatigue resistance, and long service life.

After years guiding crane teams in Asia, the Middle East, and Australia, I learned the right ropes prevent downtime and improve safety. I’ll break it down simply.

How do I select the right wire rope for a luffing crane?

Luffing cranes bend their ropes constantly. Every boom angle change adds bending stress to the outer wires and core. Ropes with compacted strands and a strong IWRC core last longer under these conditions.

Key factors to consider

| Factor | Why it matters | What I recommend |

|---|---|---|

| Bending fatigue | Frequent boom angle changes | WS compacted strands |

| Breaking load | Heavy lifting | High-tensile steel |

| Stability | Prevent hook swing | IWRC core, controlled lay |

| Lubrication retention | Reduce friction and wear | Plastic-impregnated core |

| Corrosion resistance | Outdoor/sea work | Galvanized or EPI coating |

Rotation control importance

Even if luffing cranes don’t rotate the load, rope twisting can move the hook unexpectedly. I always choose non-rotating hoist ropes like 35WXK7 or 15XK7 for maximum stability.

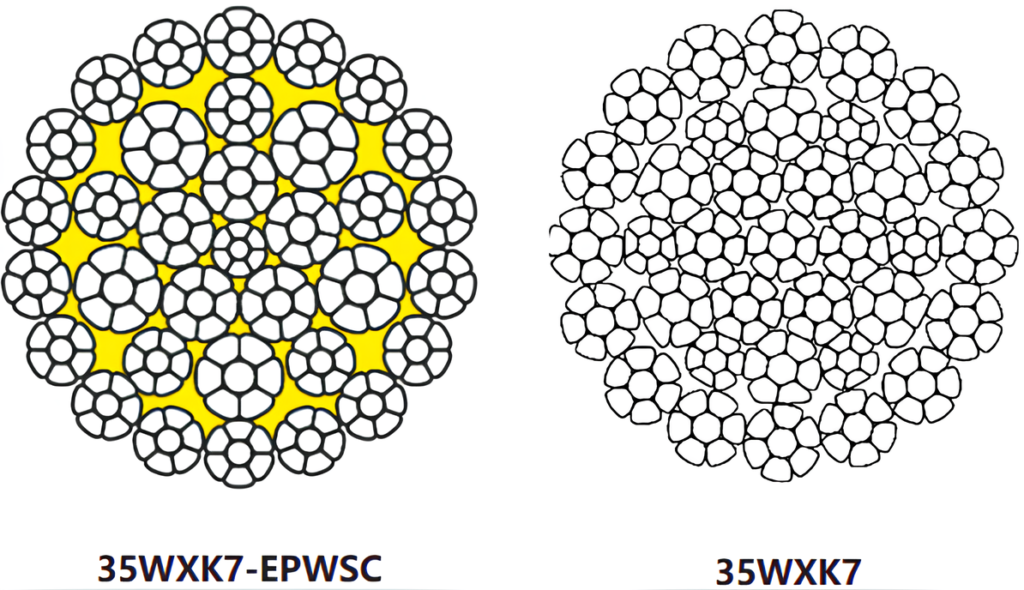

Hoist Rope: 35WXK7 and 15XK7

Hoist ropes carry the main load. They need non-rotating performance, high tensile strength, and bending fatigue resistance.

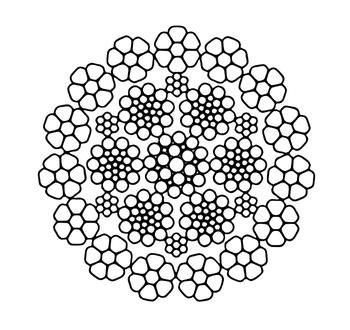

15XK7

Structure and features

| Product | Strands | Core | Feature |

|---|---|---|---|

| 35WXK7 | 35 wires per strand | IWRC | Non-rotating, flexible, fatigue-resistant |

| 15XK7 | 15 wires per strand | IWRC | Non-rotating, high breaking load, heavy-duty |

Practical advice

- 35WXK7: Medium-duty cranes or frequent bending cycles.

- 15XK7: High-capacity cranes for heavy lifting.

- Maintain lubrication for maximum lifespan.

Case example

A Singapore port crane used 35WXK7 for one year of daily operation. Minimal outer wire wear proved its fatigue resistance. Standard 19-strand ropes from other suppliers failed within six months.

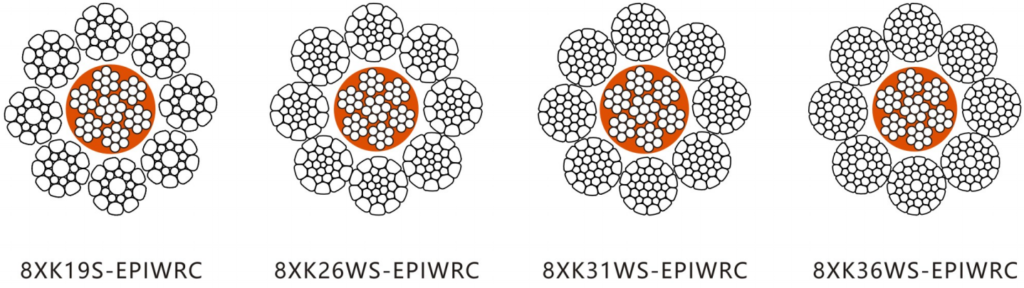

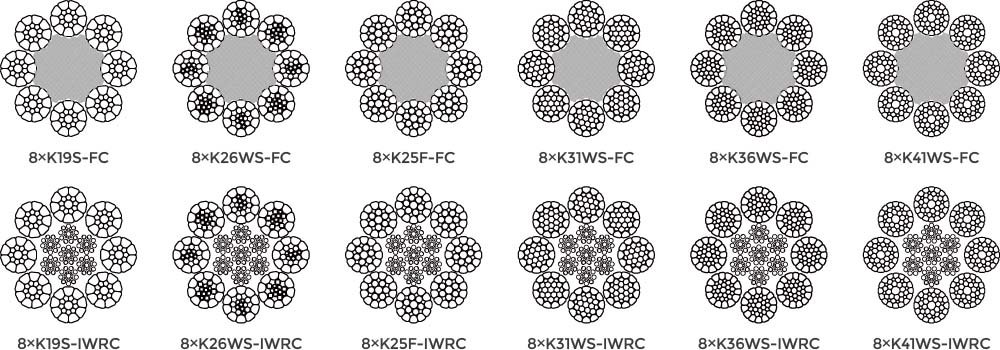

Luffing / Pendant Rope: 8XK26WS-IWRC, 8XK26WS-EPIWRC, 6XK36WS-IWRC

Luffing and pendant ropes control boom movement. They need high breaking load, flexibility, and bending fatigue resistance.

Structure and features

| Product | Strands | Core | Feature |

|---|---|---|---|

| 8XK26WS-IWRC | 8 | IWRC | Flexible, abrasion-resistant |

| 8XK26WS-EPIWRC | 8 | IWRC, Plastic-impregnated | Corrosion-resistant, long lubrication life |

| 6XK36WS-IWRC | 6 | IWRC | Heavy load, good bending performance |

Usage tips

- 8XK26WS-IWRC: Standard luffing ropes on land cranes.

- 8XK26WS-EPIWRC: Offshore or humid environments.

- 6XK36WS-IWRC: Heavy-duty pendant systems with long sheaves.

Case example

A Vietnamese crane near the coast used 8XK26WS-EPIWRC. Two years of operation showed no internal corrosion and excellent bending fatigue life.

Benefits of plastic-impregnated ropes

Plastic-impregnated ropes hold lubrication, reduce internal friction, and prevent rust. They are ideal for long-term luffing crane operations in harsh environments.

Key advantages

| Feature | Benefit |

|---|---|

| Sealed core | Prevents internal rust |

| Lubrication retention | Extends rope life |

| Reduced wire movement | Lower fatigue and broken wires |

| Smoother operation | Less noise, stable performance |

Real example

An offshore crane in Australia used 8XK26WS-EPIWRC. Despite salty air and heavy use, the rope lasted 3 years without major maintenance. Standard ropes only lasted 18 months.

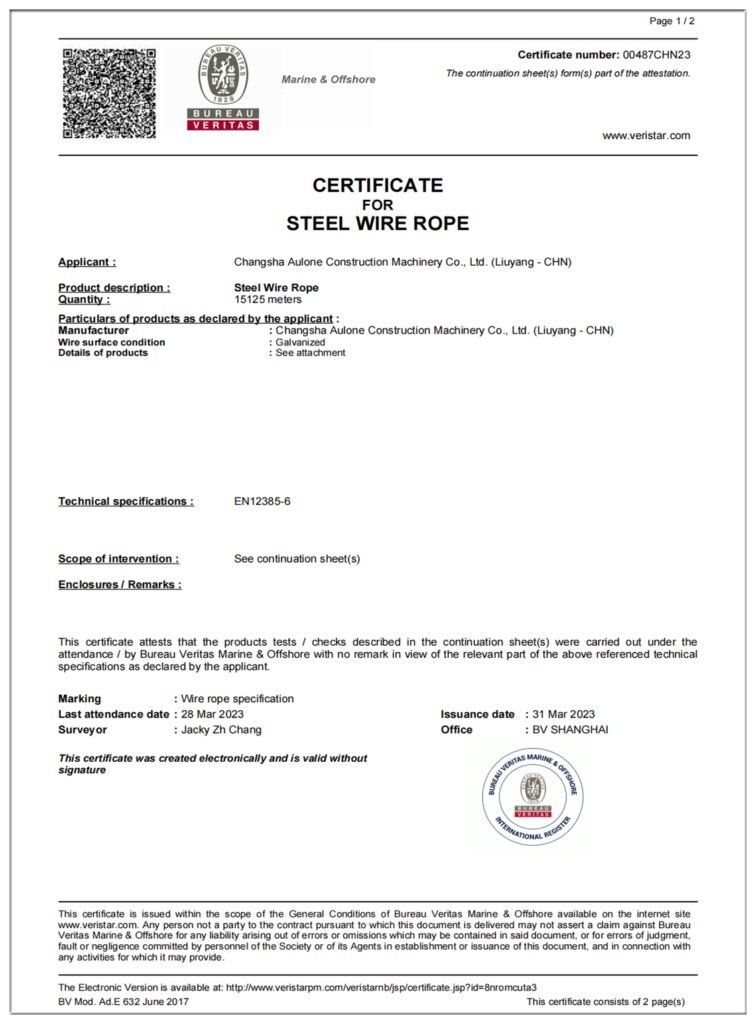

Certifications and safety standards

All ropes meet EN12385-4. Certificates like BV, CE, RMRS, DNV, ABS are available depending on client needs.

Certification details

| Certificate | Purpose |

|---|---|

| EN12385-4 | Steel rope safety standard |

| BV | Marine/offshore approval |

| DNV | Offshore and heavy-duty lifting |

| ABS | Shipyard/marine lifting |

| CE | European market compliance |

Why certification matters

Certifications ensure the rope is tested for load, bending fatigue, and safety. This reduces accidents, downtime, and regulatory issues.

Maintenance tips I always follow

- Inspect ropes every 3 months for wear or broken wires.

- Lubricate regularly to reduce friction.

- Replace hoist ropes before outer wire breaks reach critical limits.

- Keep usage records of hours and cycles.

- Use correct sheaves and drums to reduce wear.

These steps maximize rope life and prevent costly downtime.

Conclusion

Choosing the right hoist and luffing ropes, following certifications, and proper maintenance ensures safe, reliable, and long-lasting crane performance.