Your offshore rig faces harsh conditions. A failing rope means disaster and huge costs. You need a rope that survives the extreme sea environment to ensure safety and efficiency.

An offshore-grade wire rope has superior corrosion resistance, high breaking strength, and excellent fatigue life. It is specifically engineered with features like heavy galvanization and plastic impregnation to survive saltwater and extreme loads.

I remember a client who almost bought a standard rope for his rig. We talked about these key differences. That conversation saved his project from a potential failure. Let’s look at those details.

Why is Corrosion a Top Concern for Offshore Wire Ropes?

The ocean is an unforgiving place for steel. Saltwater constantly attacks it. This isn’t just about looks. It is a direct threat to your rope’s strength and your crew’s safety.

Corrosion is a top concern because it eats away the steel inside the rope. This makes the rope weaker. It lowers its breaking strength and greatly increases the risk of a sudden failure in the tough offshore environment.

The Science of Saltwater Attack

Corrosion on land is different from corrosion at sea. The salt in seawater, especially the chlorides, speeds up the chemical reaction that rusts steel. It gets deep inside the rope. It works on the inner wires you cannot see. This internal corrosion is the most dangerous. Water can get trapped between the strands. This makes the corrosion work even faster. A rope can look okay on the outside but be very weak on the inside.

Galvanization: Your First Line of Defense

To fight this, we use galvanization. This means we coat the steel wires with a layer of zinc. Zinc corrodes much slower than steel. It acts as a protective barrier. It also provides cathodic protection. This means even if the coating is scratched, the zinc sacrifices itself to protect the steel underneath.

But not all galvanization is the same. For offshore work, you need the right class.

Galvanization Classes Explained

The thickness of the zinc coating is very important. It is measured in “classes”. Using the wrong class can give you a false sense of security.

| Galvanization Class | Coating Thickness | Environment Suitability |

|---|---|---|

| Class A | Heavy | Marine, high-corrosion, saltwater spray |

| Class B | Medium | Industrial areas, high humidity, freshwater |

| Commercial | Light | Dry conditions, indoor use |

For any offshore application, from drilling lines to mooring ropes, I always recommend Class A galvanization. It provides the longest possible service life in a salty environment. It is the minimum standard for safety and reliability at sea.

How Do Breaking Strength and Fatigue Resistance Affect Performance?

An offshore rope does more than just resist rust. It lifts huge loads again and again. You need to understand its strength and endurance. This is critical for success and safety on deck.

High breaking strength ensures the rope can handle extreme single loads without snapping. Excellent fatigue resistance allows it to bend over sheaves and drums thousands of times without breaking, ensuring a long and reliable life in daily operations.

MBL vs. SWL: Know the Difference

People often mix up these two terms. It is important to know the difference for safety.

- Minimum Breaking Load (MBL): This is the force at which a new rope is expected to break. We test samples from every production batch in our factory to guarantee this strength. You should never, ever work at or near the MBL.

- Safe Working Load (SWL): This is the maximum load the rope should ever carry in service. The SWL is a fraction of the MBL. It is calculated by dividing the MBL by a safety factor.

The safety factor is not a guess. It depends on the application. For lifting people, the safety factor might be 10:1 or higher. For lifting equipment, it might be 5:1. Always follow the crane manufacturer’s or a qualified engineer’s recommendation for the safety factor.

The Invisible Killer: Bending Fatigue

A rope rarely breaks from a single overload. More often, it fails from fatigue. Every time a rope bends around a sheave or a drum, its individual wires bend. This repeated bending causes tiny cracks to form over time. Eventually, these cracks grow, and the wire breaks. When enough wires break, the whole rope fails.

The main factors affecting fatigue are:

- Load: Heavier loads cause more fatigue.

- Bend Radius: Bending over a small sheave is much worse than bending over a large one.

- Frequency: More bending cycles mean a shorter life.

Rope Construction Matters

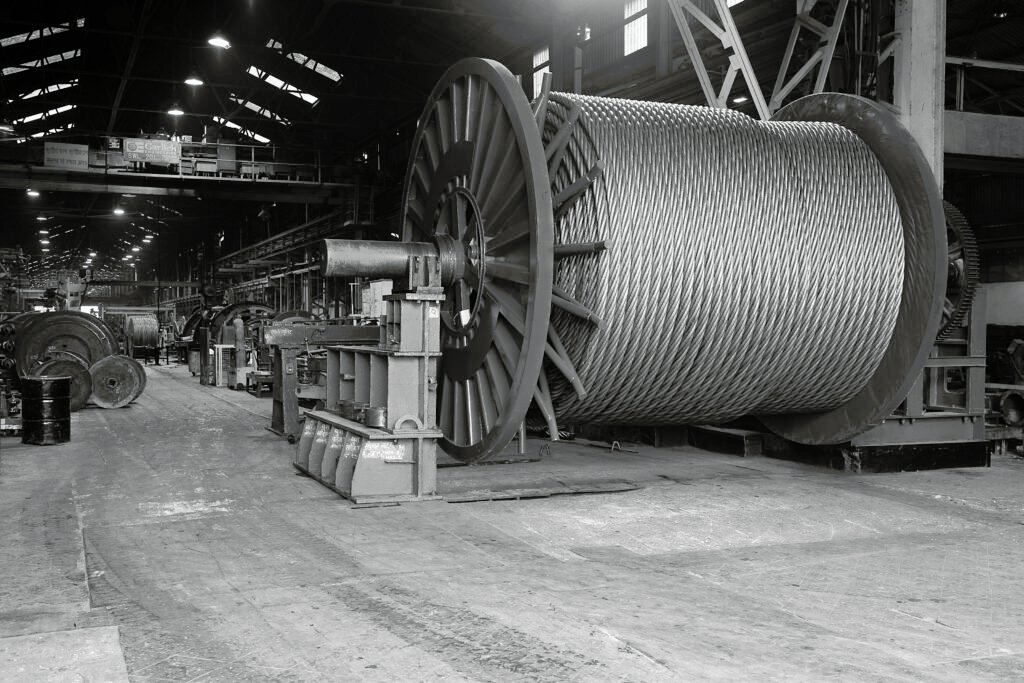

The way a rope is built has a big impact on its performance. Different constructions offer different balances of strength, flexibility, and resistance to abrasion and fatigue.

| Rope Construction | Flexibility | Abrasion Resistance | Fatigue Resistance |

|---|---|---|---|

| 6×19 Class | Low | High | Low |

| 6×36 Class | High | Medium | High |

| 8×25 Class | Very High | Low | Very High |

For many offshore crane and drilling applications, a 6x36 class rope is a good choice. It offers a great balance of fatigue resistance and durability. For applications that need even more flexibility, an 8-strand rope might be better. We can help you select the exact construction for your specific machine and operation.

What is a Plastic Impregnated Rope and Why is it Used Offshore?

Have you seen ropes that look like they are shiny or coated in plastic? That is not just for looks. This feature provides a powerful advantage in marine environments and is called plastic impregnation.

A Plastic Impregnated (PI) rope has a special polymer that fills the empty spaces between its steel strands. This process locks in lubricant, keeps out saltwater and dirt, and improves fatigue life by stopping the strands from rubbing together.

How Plastic Impregnation Works

During manufacturing, we draw the rope through a process that injects a special polymer deep into its core. The plastic fills all the internal spaces. It completely encases each strand within the rope. This creates a solid, stable rope structure. It also creates a barrier between the inner and outer parts of the rope.

This is very different from just putting extra grease on the outside. External grease can be washed off or get filled with sand. Plastic impregnation is a permanent, internal part of the rope’s structure.

Key Benefits of a PI Rope

Why do we go to this extra effort? For offshore work, the benefits are huge.

- It seals in lubrication. The factory lubricant is essential for the rope’s life. The plastic layer keeps it exactly where it needs to be, on the internal wires.

- It keeps out contaminants. Saltwater, sand, and grit cannot get inside the rope to cause corrosion and abrasion. This is a massive benefit for ropes working on a sandy drill floor or near the splash zone.

- It reduces internal friction. The plastic acts as a cushion between the strands. As the rope bends, the strands slide on the smooth plastic instead of grinding against each other. This dramatically improves fatigue life.

- It improves structural stability. The plastic helps the rope keep its round shape and prevents crushing on the drum.

Standard Rope vs. Plastic Impregnated Rope

A good quality PI rope will almost always outperform a standard rope in a harsh marine environment. The initial cost is higher. But the longer service life and increased safety often make it a much better investment in the long run.

| Feature | Standard Lubricated Rope | Plastic Impregnated Rope |

|---|---|---|

| Internal Lubrication | Can dry out or be washed away over time. | Locked in for the life of the rope. |

| Contaminant Ingress | High risk from water, sand, and dirt. | Sealed against all external contaminants. |

| Internal Corrosion | A high risk, difficult to inspect. | The risk is very significantly reduced. |

| Fatigue Life | Good | Excellent to Superior |

| Drum Crushing | More susceptible to flattening. | More resistant to crushing and deformation. |

Are Certifications Like DNV or ABS Really Necessary?

Some people see certifications as just extra paperwork and cost. I see them as a promise of quality. For high-stakes offshore work, this promise isn’t just nice to have. It is often a strict requirement.

Yes, certifications are often necessary. A certificate from a body like DNV, ABS, or RMRS proves the rope was made and tested to strict international rules. It gives traceable proof of quality, giving you and regulators confidence in the product’s safety.

Who are the Classification Societies?

Groups like DNV (Det Norske Veritas) and ABS (American Bureau of Shipping) are called classification societies. They are independent organizations. Their job is to set technical standards for ships and offshore structures. They want to protect life, property, and the environment.

When an offshore rig or vessel is “classed” by DNV or ABS, it means all its critical components, including wire ropes, must meet their standards. You cannot use a non-certified rope on a classed vessel.

What a Certificate Guarantees

Getting a rope certified is a serious process. It is not just about a final test. It means:

- Traceable Materials: We must prove the steel used in the rope came from an approved mill and has the correct chemical properties.

- Witnessed Testing: An inspector, or “surveyor,” from the classification society must watch us perform the break test. They witness the test with their own eyes to ensure it is done correctly and the rope passes.

- Verified Manufacturing: The surveyor often inspects our manufacturing process to ensure it meets their requirements.

- Official Documentation: If everything is correct, the society issues a unique certificate for that specific rope, linking it to the test results and production details.

This creates a chain of trust. We trust our steel supplier. You trust us. And the regulator trusts the certificate. In my factory, we have 10 production lines ready to produce certified ropes. We can provide certificates from DNV, ABS, RMRS, BV, and others.

Common Certifications and What They Mean

| Certification Body | Primary Focus | Region/Industry |

|---|---|---|

| DNV | Maritime, Oil & Gas apecialist | Global, strong in Europe, North Sea |

| ABS | Maritime, Offshore structures | Global, strong in the Americas, Gulf of Mexico |

| RMRS | Maritime, Shipping, Ice-class vessels | Russia, CIS countries |

| CE Marking | Basic Product Safety Compliance | Mandatory for sale in the European Economic Area |

You must check what certification is required for your specific vessel or operation. Using a rope with the wrong or no certificate can get your operation shut down during an inspection.

What Is the Correct Way to Inspect and Maintain Offshore Ropes?

Buying the best rope is only the first step. Proper care is what guarantees a long and safe service life. If you neglect inspection, you put your people and your entire operation at risk.

Correct inspection involves regular visual checks for broken wires, corrosion, and damage. It also includes periodic non-destructive testing (NDT). Proper maintenance means correct lubrication, careful spooling, and keeping good records to track the rope’s condition.

Daily Visual Inspection Checklist

A qualified person should visually inspect the active section of the rope every day or before each shift. You don’t need special tools for this. You are looking for obvious danger signs.

- Look for groups of broken wires.

- Look for signs of kinking, crushing, or birdcaging.

- Look for signs of heavy external corrosion or abrasion.

- Check the end termination (socket or splice) for damage or slippage.

- Watch how the rope spools onto the drum. Is it smooth and even?

If you see anything that concerns you, the rope should be more closely examined before it is used.

Knowing When to Retire a Rope

All wire ropes wear out and must be replaced. The decision to retire a rope is based on clear rules, not feelings. International standards like ISO 4309 provide detailed retirement criteria. They are based on the number of visible broken wires, diameter reduction, corrosion, and deformation.

| Type of Damage | Retirement Criteria (General Example) |

|---|---|

| Broken Wires (Running Rope) | More than 6 in one lay length, or 14 in one meter. |

| Broken Wires (Standing Rope) | More than 3 in one lay length. |

| Diameter Reduction | More than 7% of the rope’s nominal diameter. |

| Corrosion | Heavy pitting, or the rope feels stiff and not flexible. |

| Deformation | Any visible kink, birdcage, loop, or crushing. |

A “lay length” is the distance along the rope for one strand to make a full turn around the rope’s core. You must measure it on the rope. Always follow the specific criteria from the rope manufacturer or the relevant standard for your industry. Keeping a rope in service past these limits is extremely dangerous.

Lubrication is Key

Even galvanized and plastic-impregnated ropes need proper lubrication in service. The outer wires still rub against sheaves and drums. A good pressure lubricant helps reduce this external friction. It also provides an extra barrier against corrosion. Follow the rope or lubricant manufacturer’s guide on what type of lubricant to use and how to apply it.

Conclusion

Choosing an offshore rope is about safety and uptime. You must focus on corrosion resistance, strength, and certified quality. The right rope, properly maintained, is a critical investment.