Struggling with rope failures can halt your projects. Choosing the right auxiliary hoist rope prevents costly downtime and keeps your operations safe.

I remember the first time a rope snapped mid-lift—it was a harsh lesson. Since then, I’ve learned exactly what to look for in auxiliary hoist ropes to avoid such incidents.

What Are the Key Features of an Auxiliary Hoist Rope?

Choosing the right rope is more than just picking a strong line. The details matter for safety and efficiency.

Auxiliary hoist ropes must balance strength with flexibility. A rigid rope might break under stress. A flexible rope can handle complex lifts.

| Feature | Importance | Example |

|---|---|---|

| Tensile Strength | Prevents snapping under load | Galvanized wire ropes for mining lifts |

| Flexibility | Allows smooth operation over pulleys | Compacted 35WXK7 ropes for cranes |

| Corrosion Resistance | Extends rope lifespan | Plastic-impregnated ropes in marine use |

Steel, stainless steel, or plastic-coated ropes each offer unique advantages. Galvanized ropes resist rust. Stainless steel ropes handle harsh environments. Plastic-impregnated ropes reduce abrasion.

| Material | Best Use | Lifespan |

|---|---|---|

| Galvanized | Outdoor cranes | 5-8 years |

| Stainless Steel | Marine lifts | 8-12 years |

| Plastic-Impregnated | Heavy-duty hoists | 6-10 years |

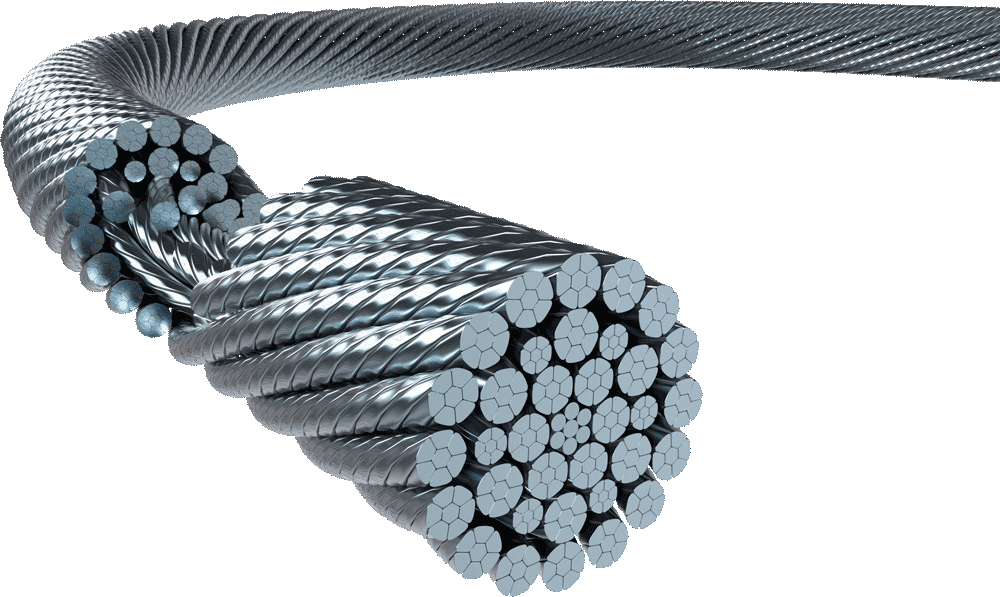

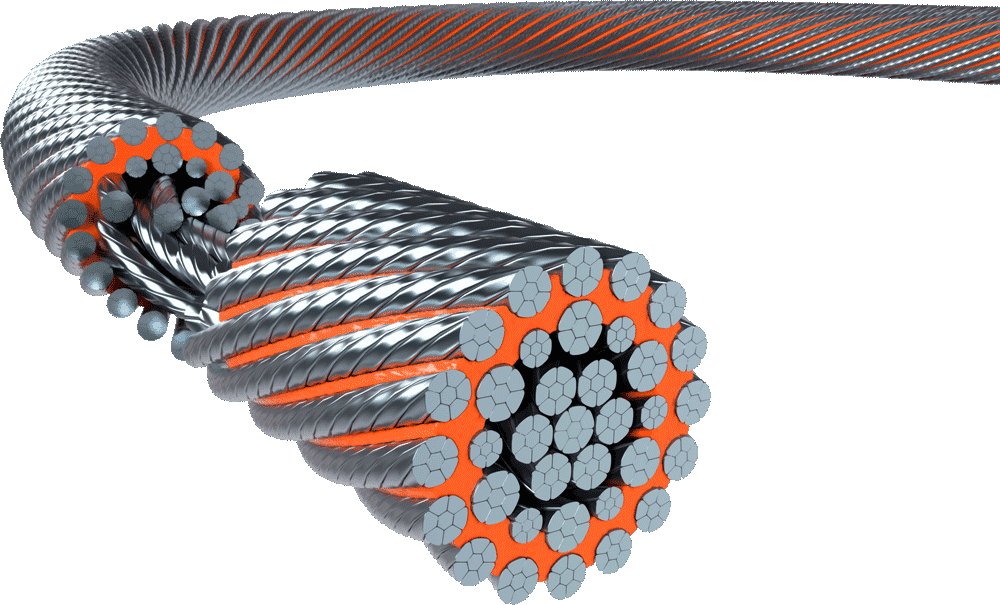

How Does Rope Construction Affect Performance?

The internal structure of a rope determines its rotation resistance and load capacity. Construction is critical for reliable performance.

Strand arrangement influences rope flexibility and strength. Wire ropes can have fiber cores (more flexible) or steel cores (higher load capacity).

| Core Type | Benefits | Drawbacks |

|---|---|---|

| IWRC (Steel Core) | High strength, low elongation | Less flexible |

| FC (Fiber Core) | Flexible, lighter | Lower load capacity |

Rotation-resistant ropes prevent sudden twisting during lifting. They are crucial when operating with hoists that lift heavy, uneven loads.

What Safety Standards Should You Look For?

Safety cannot be compromised. Understanding standards helps ensure you select a certified, reliable rope.

Auxiliary hoist ropes should comply with EN12385-4, and certificates like BV, CE, DNV, or ABS provide proof of quality and reliability.

| Certificate | Authority | Scope |

|---|---|---|

| BV | Bureau Veritas | Global lifting safety standards |

| CE | European Union | Compliance with EU machinery safety |

| DNV | Det Norske Veritas | Offshore and marine applications |

| ABS | American Bureau of Shipping | Maritime equipment safety |

How to Maintain Auxiliary Hoist Ropes for Longevity?

Proper maintenance extends rope life and prevents unexpected failures. Even the strongest rope wears out without care.

Inspect ropes visually for broken wires, corrosion, or core damage. Store ropes in dry, shaded areas. Lubricate periodically to reduce friction and wear.

| Maintenance Step | Frequency | Notes |

|---|---|---|

| Visual Inspection | Weekly | Look for broken strands |

| Lubrication | Monthly | Use rope-specific lubricants |

| Storage | Always | Keep off concrete, away from moisture |

| Replacement | As needed | Follow manufacturer guidelines |

Conclusion

Choosing the right auxiliary hoist rope, understanding its features, construction, certifications, and maintenance ensures safety, efficiency, and durability in lifting operations.