Are you struggling to find reliable wire ropes that meet stringent quality standards? We understand the frustration of uncertain sourcing and the pressure to deliver.

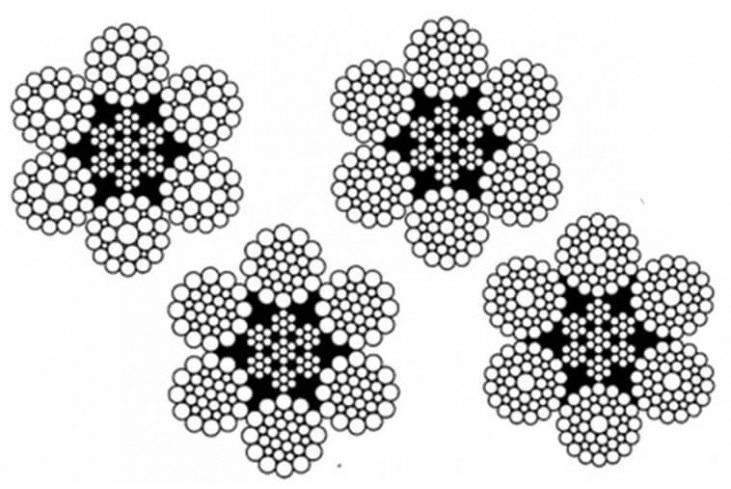

When selecting wire ropes, Class 6×19 IWRC and Fiber Core are often the go-to options due to their balanced strength, flexibility, and affordability, making them suitable for a wide range of industrial uses.

Let me tell you about a time when choosing the right wire rope made all the difference. It was a crucial project, and the stakes were high. The right choice meant success, the wrong one could lead to costly delays.

Why is the core of a wire rope so important for its performance?

Understanding the core’s impact is key to selecting the best wire rope. It directly influences strength and operational characteristics.

The core provides essential internal support, affecting the rope’s overall strength, flexibility, and resistance to crushing.

The Role of the Independent Wire Rope Core (IWRC)

An Independent Wire Rope Core provides superior strength and stability. It’s like giving the wire rope its own internal skeleton of steel. This makes it more resistant to crushing and deformation, especially under heavy loads or in demanding environments. Think of it as a robust internal structure that can take a beating. For applications requiring maximum strength and durability, IWRC is often the preferred choice. The steel wires in the core are specifically designed to bear significant loads, ensuring the rope maintains its integrity even under extreme stress.

Here’s a breakdown of its benefits:

| Feature | Description |

|---|---|

| Strength | Higher tensile strength compared to fiber cores. |

| Crush Resistance | Excellent resistance to crushing and deformation under load. |

| Heat Resistance | Performs better in elevated temperature conditions. |

| Stability | Maintains its shape and integrity more effectively under stress. |

In general, IWRC ropes are ideal for heavy lifting operations, such as those found in crane applications, where durability and load-bearing capacity are paramount. They are also well-suited for winches and other equipment that face constant, heavy strain.

Understanding the Fiber Core (FC) in Wire Ropes

A Fiber Core, often made from synthetic materials like polypropylene or nylon, offers a different set of advantages. It makes the wire rope lighter and more flexible. This added flexibility is crucial for applications where the rope needs to bend easily around pulleys or drums without kinking or losing its structural integrity. While it might not offer the same absolute strength as an IWRC, its flexibility can significantly improve handling and reduce wear in certain operational contexts.

Here’s a look at the advantages of a fiber core:

| Feature | Description |

|---|---|

| Flexibility | Greater flexibility, making it easier to handle and spool. |

| Weight | Lighter weight, which can be beneficial in some applications. |

| Cost | Generally more economical than IWRC ropes. |

| Corrosion | Less prone to internal corrosion compared to steel cores. |

When choosing between IWRC and Fiber Core, consider the specific demands of your operation. For instance, if you’re operating in corrosive environments, a fiber core rope might offer better longevity due to its resistance to internal rust. However, if your primary concern is the absolute maximum load capacity and resistance to deformation, the IWRC would be the more suitable option.

How does the construction of 6×19 relate to its versatility?

The 6×19 construction is a sweet spot for many applications. It offers a good balance between strength and flexibility. This means it can handle significant loads while still being manageable for everyday use.

This construction means the rope is made of six main strands, with 19 wires in each strand. This pattern provides a robust yet pliable structure. It’s a design that has stood the test of time because it works so well in so many different situations.

Let’s break down why this specific construction is so popular:

- Flexibility for Ease of Handling: The 19 wires per strand allow for good flexibility. This makes the rope easier to bend, wrap, and maneuver, which is a big plus during installation and operation.

- Strength for Demanding Tasks: Despite its flexibility, the total number of wires and the way they are laid up provide substantial tensile strength. This allows it to carry significant loads, making it suitable for a variety of industrial uses, from lifting to pulling.

- Durability Against Abrasion: The construction also offers decent resistance to abrasion on the outer surface. This is important because ropes often rub against machinery or other elements, and wear and tear can be a significant factor in their lifespan.

- Adaptability to Various Applications: Because of this balanced combination of properties, Class 6×19 ropes find their way into many different industries. They are commonly used in cranes, excavators, general hoisting, and even some specialized applications.

Consider a scenario where a crane needs to lift heavy materials repeatedly. The 6×19 IWRC construction provides the necessary strength to handle these loads safely, while its flexibility ensures it can feed smoothly through the crane’s sheave blocks without undue stress. On the flip side, in applications like elevator ropes, where smooth operation and flexibility are critical, a 6×19 Fiber Core might be preferred for its bending capabilities and lighter weight.

How do certifications and compliance affect wire rope selection?

Choosing wire ropes with the right certifications is crucial for safety and reliability in many industries. These approvals demonstrate that the products meet specific quality and performance standards. This can be a major factor, especially for international trade or highly regulated sectors.

When you need to ensure your wire ropes meet international standards, looking for certifications like BV, CE, RMRS, DNV, or ABS is important. These are recognized globally and show that the rope has been tested and verified against strict performance criteria. For example, a company might need a DNV-certified rope for offshore applications where safety is paramount.

Here’s why these certifications matter:

| Certification Body | Typical Areas of Focus | Importance for Users |

|---|---|---|

| BV (Bureau Veritas) | Marine, offshore, industrial | Ensures products meet international maritime and industrial safety standards. |

| CE | General product safety in Europe | Indicates conformity with health, safety, and environmental protection standards within the EEA. |

| RMRS | Russian Maritime Register of Shipping | Essential for operations in Russian waters or importing goods into Russia. |

| DNV | Maritime, oil & gas, renewable energy | Guarantees high standards of safety and performance, especially in harsh environments. |

| ABS | American Bureau of Shipping (Marine and offshore) | Certifies that equipment meets safety and structural integrity standards for marine use. |

These certifications are not just paper certificates; they represent a commitment to quality and safety. For businesses like purchasing managers from large corporations or mining companies, this assurance can prevent costly accidents and ensure compliance with regulations. For Andri, our typical customer, who previously worked with top-tier German brands, these certifications would align with the expectation of high standards.

Moreover, compliance with standards like EN12385-4 is vital. This European standard specifically covers certain types of steel wire ropes for general hoisting purposes. Adhering to such standards means the rope has passed rigorous testing for properties like tensile strength, minimum breaking force, and dimensional accuracy, ensuring predictability in its performance.

What are the advantages of galvanized and plastic-impregnated wire ropes?

Opting for galvanized or plastic-impregnated wire ropes can significantly enhance their lifespan and performance in various environmental conditions. These treatments protect the steel wires from corrosion and improve the rope’s overall integrity.

Galvanization adds a protective zinc coating, shielding the steel from rust and corrosion. Plastic impregnation, often a polymer filling the core and outer strands, further protects against moisture and external damage, and can also improve flexibility.

Let’s look at how these specific options benefit you:

Galvanized Wire Rope: Fighting Corrosion for Longevity

Galvanized wire ropes are coated with a layer of zinc. This coating acts as a sacrificial barrier. When exposed to moisture, salt, or other corrosive elements, the zinc corrodes before the steel. This is crucial for applications in marine environments, or any place where the rope will be exposed to the elements. The process involves either hot-dip galvanizing or electro-galvanizing, with hot-dip generally providing a thicker, more robust coating.

Key benefits of galvanized wire ropes include:

- Enhanced Corrosion Resistance: Significantly extends the life of the rope in wet or corrosive conditions.

- Improved Durability: The zinc coating can also offer a degree of abrasion resistance to the outer wires.

- Cost-Effectiveness: While there is an added cost for galvanization, the extended service life often makes it a more economical choice over time compared to non-galvanized ropes in demanding environments.

For instance, a crane wire rope used outdoors, exposed to rain and humidity, would benefit immensely from galvanization, ensuring it maintains its strength and integrity for longer. Similarly, marine wire ropes commonly utilize galvanization for protection against saltwater.

Plastic Impregnated Wire Rope: Added Protection and Flexibility

Plastic impregnated wire ropes have a special polymer material infused into the core and sometimes between the outer strands. This fusion offers several advantages. Firstly, it minimizes internal friction between the wires and strands as the rope flexes, improving its fatigue life. Secondly, it creates a barrier against dirt, water, and chemicals, preventing internal corrosion and wear.

The benefits of plastic impregnation are:

- Superior Internal Protection: Prevents moisture and contaminants from reaching the steel core and wires, crucial for resisting internal corrosion.

- Increased Flexibility: The plastic can lubricate the wires, making the rope more pliable and easier to handle, especially during spooling and bending around pulleys.

- Reduced Rope Fatigue: By minimizing internal friction, the rope can withstand more bending cycles before failure.

- Enhanced Load Distribution: The plastic filling can help distribute stress more evenly across the rope’s cross-section under load.

A prime example where plastic impregnation is highly advantageous is in elevator wire ropes. These ropes undergo constant bending and require smooth, reliable operation. The impregnated plastic ensures a longer service life and consistent performance, minimizing the risk of a sudden breakdown. Similarly, for applications involving frequent spooling and unspooling, like on winches, the enhanced flexibility and reduced wear offered by plastic impregnation are invaluable. Combining plastic impregnation with galvanization, as is often done, provides a comprehensive protection package for the wire rope.

Conclusion

Class 6×19 IWRC and Fiber Core offer balanced strength and flexibility, with certifications ensuring quality and treatments enhancing durability for diverse industrial needs.