Lifting heavy loads is risky without reliable wire ropes. Poor choices can lead to accidents, downtime, and extra costs. I’ve experienced this, which is why I focus on selecting the right rope for each crane.

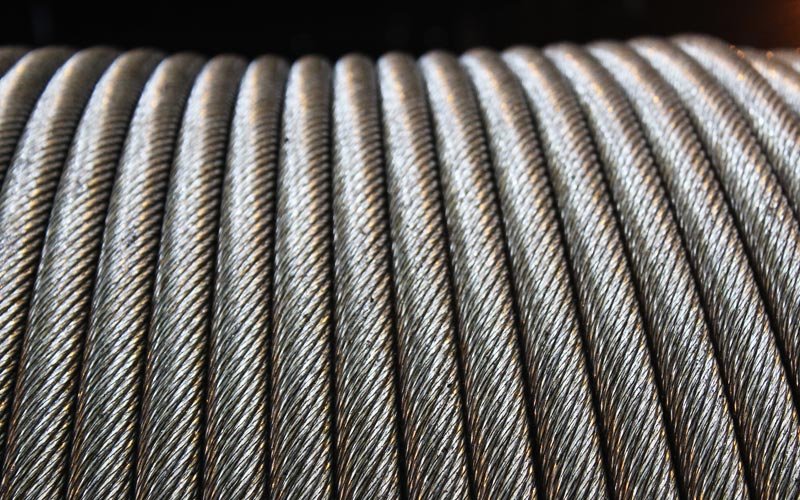

Metric overhead crane wire ropes provide precise load handling, durability, and safety, making them essential for modern industrial lifting.

Using the wrong rope can be costly. Let me share my insights and lessons from working with cranes and wire ropes over the years.

How Do Metric Overhead Crane Wire Ropes Differ from Standard Wire Ropes?

Wire ropes may appear similar, but metric overhead crane ropes are designed specifically for lifting operations. They follow strict standards for load, flexibility, and rotation resistance.

Metric ropes have defined diameters, load ratings, and EN12385-4 compliance, ensuring cranes operate safely under heavy loads.

Key Specifications

Metric overhead ropes are measured in millimeters for exact matching with crane drums and sheaves. Even small differences affect performance.

| Feature | Benefit |

|---|---|

| Diameter in mm | Ensures precise fit on drums |

| EN12385-4 compliance | Guarantees safety and legal adherence |

| High tensile strength | Handles maximum load safely |

| Customizable core | Fits specific crane design needs |

I once tested two ropes of slightly different diameters on the same crane. One caused spooling issues, while the other ran smoothly. Even minor mismatches can cause wear, downtime, and maintenance costs. Choosing the right rope avoids these problems.

What Are the Main Materials Used in Metric Crane Wire Ropes?

The material of the rope defines its performance. Steel is the base, but protective coatings or impregnation extend life. Options include galvanized, plastic-impregnated, and stainless steel.

High-grade steel with galvanization or plastic impregnation improves corrosion resistance and reduces wear, prolonging service life.

Material Selection

Material choice depends on the environment. Indoor cranes often use plain steel. Outdoor cranes, ports, and marine applications need corrosion protection.

| Material Type | Advantages | Typical Use |

|---|---|---|

| Galvanized Steel | Rust protection | Outdoor, marine |

| Plastic-Impregnated | Reduced friction, longer life | Heavy-duty lifting |

| Stainless Steel | Resistant to corrosion | Marine, chemical environments |

I remember an outdoor port crane where switching to galvanized ropes doubled the service life. Proper material selection prevents frequent replacements, reduces costs, and improves safety.

How Does Rope Construction Affect Performance?

Rope construction includes strand count, core type, and lay direction. These influence strength, flexibility, wear, and rotation resistance.

Compacted strands, rotation-resistant cores, and proper lay direction ensure safe operation, smooth spooling, and long rope life.

Understanding Construction

Ropes can be round, shaped, or compacted. Core types include fiber core (FC) and independent wire rope core (IWRC).

| Construction | Strength | Flexibility | Application |

|---|---|---|---|

| 6×36 WS IWRC | High | Medium | Overhead cranes |

| 8×26 WS FC | Medium | High | Light-duty lifting |

| Compacted | Very high | Medium | Heavy-duty lifting |

In my experience, IWRC cores are essential for heavy overhead cranes. FC cores give flexibility but lower load capacity. Compacted strands improve breaking load without sacrificing flexibility. These small differences matter when lifting heavy, high-value loads.

How to Ensure Compliance and Certification?

Certifications confirm rope quality and safety. EN12385-4, BV, CE, RMRS, DNV, and ABS certificates demonstrate adherence to strict manufacturing and testing standards.

Certified ropes meet load, durability, and safety requirements, essential for industrial operations and regulatory compliance.

Certification Importance

Using uncertified ropes may reduce crane lifespan and increase accident risk. Certificates guarantee tensile tests, manufacturing consistency, and quality control.

| Certificate | Scope | Benefit |

|---|---|---|

| EN12385-4 | European standard | Legal compliance |

| BV & CE | Quality & safety | Export approval |

| RMRS, DNV, ABS | Maritime & industrial | Global usage |

I always verify certificates before buying ropes. Doing this once saves countless hours during inspections and prevents costly legal issues. Certificates also reassure clients and auditors that operations meet international standards.

How Do You Choose the Right Rope for Your Crane?

Choosing the right rope requires considering crane load, operating frequency, environment, and rope diameter. Material, construction, and core type must fit specific requirements.

The right rope balances load capacity, durability, and operational safety for each crane application.

Selection Guidelines

Assess crane type, working frequency, and environmental conditions. Include a safety margin in load calculations.

| Criteria | Recommendation |

|---|---|

| Working Load Limit | ≥ required load + 25% |

| Rope Material | Galvanized or plastic-impregnated for outdoor use |

| Diameter | Match drum & sheave exactly |

| Construction | IWRC for heavy-duty cranes |

I’ve seen cranes fail due to mismatched rope diameters. Even minor errors cause spooling issues and premature wear. Selecting the right rope ensures safety, reduces downtime, and increases crane lifespan.

What Maintenance Practices Extend Rope Life?

Rope maintenance is as important as selection. Regular inspection, lubrication, and proper spooling prevent wear and extend service life.

Consistent maintenance reduces failures, increases safety, and lowers replacement costs.

Maintenance Tips

Check for broken wires, corrosion, or core damage regularly. Lubricate the rope to reduce friction. Spool correctly to avoid crushing or kinking.

| Maintenance Task | Frequency | Benefit |

|---|---|---|

| Visual inspection | Weekly | Detect wear early |

| Lubrication | Monthly | Reduce friction and rust |

| Correct spooling | Each use | Prevent deformation |

I remember one crane with poorly spooled ropes. Frequent rope replacements were needed. After training the team on proper spooling and lubrication, rope life doubled. Proper care saves money and prevents accidents.

Conclusion

Metric overhead crane wire ropes ensure safe, efficient, and long-lasting lifting operations. Proper material, construction, certification, and maintenance make all the difference.